Service manual

Table Of Contents

G420F(FE) Service Manual Chapter 1. General Information 10

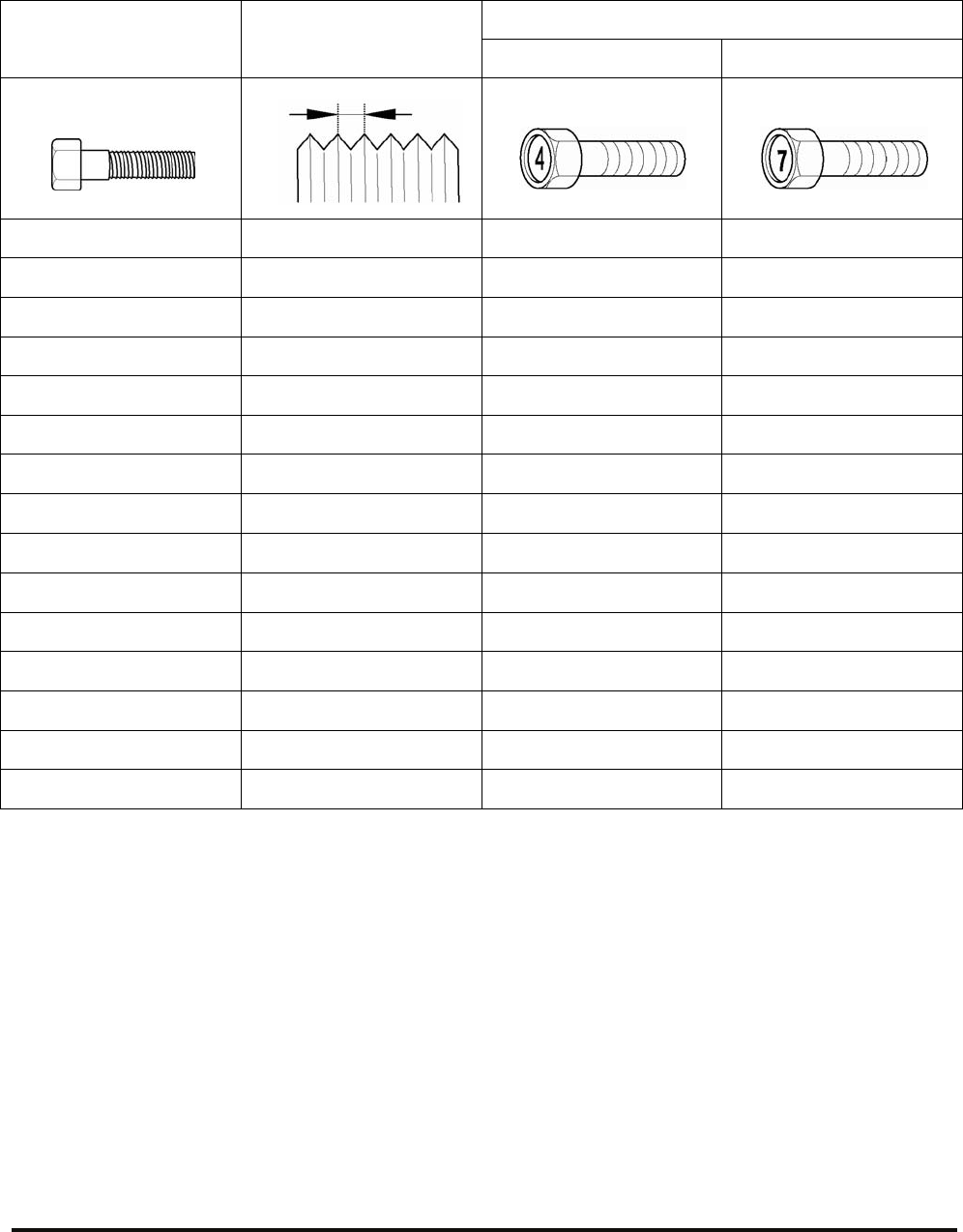

Tightening Torque

Tightening Torque Table of Standard Parts

Torque (kg·m)

Bolt nominal

diameter(mm)

Pitch(mm)

Head mark 4 Head mark 7

M5 0.8 0.3 ~ 0.4 0.5 ~ 0.6

M6 1.0 0.5 ~ 0.6 0.9 ~ 1.1

M8 1.25 1.2 ~ 1.5 2.0 ~ 2.5

M10 1.25 2.5 ~ 3.0 4.0 ~ 5.0

M12 1.25 3.5 ~ 4.5 6 ~ 8

M14 1.2 7.5 ~ 8.5 12 ~ 14

M16 1.5 11 ~ 13 18 ~ 21

M18 1.5 16 ~ 18 26 ~ 30

M20 1.5 22 ~ 25 36 ~ 42

M22 1.5 29 ~ 33 48 ~ 55

M24 1.5 37 ~ 42 61 ~ 70

M5 0.8 0.3 ~ 0.4 0.5 ~ 0.6

M6 1.0 0.5 ~ 0.6 0.9 ~ 1.1

M8 1.25 1.2 ~ 1.5 2.0 ~ 2.5

M10 1.25 2.5 ~ 3.0 4.0 ~ 5.0

NOTE: The torques shown in the table are standard

vales under the following conditions.

1. Nuts and bolt are made of steel bar and

galvanized.

2. Galvanized plain steel washers are inserted.

3. All nuts, bolts, plain washers are dry.

NOTE: The torques shown in the table are not

applicable,

1. When spring washers, toothed washers and the

like are inserted.

2. If plastic parts are fastened.

3. If oil is applied to threads and surfaces.

NOTE: If you reduce the torques in the table to the

percentage indicated below under the following

conditions, it will be the standard value.

1. If spring washers are used : 85%

2. If threads and bearing surfaces are stained with

oil: 85%