GSX Installation Manual 2019

3

Do NOT let refrigerant lines come in direct contact with plumbing,

ductwork, floor joists, wall studs, floors, and walls. When running

refrigerant lines through a foundation or wall, openings should

allow for sound and vibration absorbing material to be placed or

installed between tubing and foundation. Any gap between

foundation or wall and refrigerant lines should be filled with a

pliable silicon-based caulk, RTV or a vibration damping material.

Avoid suspending refrigerant tubing from joists and studs with

rigid wire or straps that would come in contact with the tubing.

Use an insulated or suspension type hanger. Keep both lines

separate and always insulate the suction line.

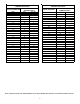

These sizes are recommended for line lengths of 79 feet or

less to obtain optimum performance. For alternate line sizing

options or runs of more than 79 feet, refer to TP-107 R-410A

Long Line Set Application Guidelines or contact your distributor

for assistance.

Cond

Unit

Tons Suct Liq Suct Liq Suct Liq

1 1/2 5/8 1/4 3/4 3/8 3/4 3/8

2 5/8 1/4 3/4 3/8 3/4 3/8

2 1/2 5/8 1/4 3/4 3/8 7/8 3/8

3 3/4 3/8 7/8 3/8 1 1/8 3/8

3 1/2 7/8 3/8 1 1/8 3/8 1 1/8 3/8

4 7/8 3/8 1 1/8 3/8 1 1/8 3/8

5 7/8 3/8 1 1/8 3/8 1 1/8 3/8

Line Diameter (In. OD)

RECOMMENDED INTERCONNECTING TUBING (Ft)

0-24 25-49 50-79*

*

Lines greater than 79 f eet in length or v ertical elev ation changes more than

50 f eet refer to TP-107 R-410A Long Line Set Application Guidelines or

contact your distributor for assistance.

Insulation is necessary to prevent condensation from forming

and dropping from the suction line. Armflex (or satisfactory

equivalent) with 3/8” min. wall thickness is recommended. In

severe conditions (hot, high humidity areas) 1/2” insulation may

be required. Insulation must be installed in a manner which

protects tubing from damage and contamination.

Existing Line Sets

Where possible, drain as much residual compressor oil from

existing systems, lines, and traps; pay close attention to low

areas where oil may collect. Use of an approved flushing agent

is recommended followed by a nitrogen purge to remove any

remaining flushing agent from the lines or indoor coil.

Replacement of indoor coil is recommended.

NOTE: If using existing indoor coil and changing refrigerant

types, ensure the indoor coil and metering device are compatible

with the type of refrigerant being used. If new indoor coil is

required check spec sheet or AHRI for approved coil. If system

is being replaced due to compressor electrical failure, assume

acid is in system. Refer to Service Procedure S-115

Compressor Burnout in service manual for clean-up procedure.

Burying Refrigerant Lines

If burying refrigerant lines can not be avoided, use the following

checklist.

1. Insulate liquid and suction lines separately.

2. Enclose all underground portions of the refrigerant lines

in waterproof material (conduit or pipe) sealing the ends

where tubing enters/exits the enclosure.

3. If the lines must pass under or through a concrete slab,

ensure lines are adequately protected and sealed.

Refrigerant Line Connections

IMPORTANT

To avoid overheating the service valve, TXV valve, or filter

drier while brazing, wrap the component with a wet rag, or

use a thermal heat trap compound. Be sure to follow the

manufacturer’s instruction when using the heat trap

compound. Note: Remove Schrader valves from service

valves before brazing tubes to the valves. Use a brazing

alloy of 2% minimum silver content. Do not use flux.

Torch heat required to braze tubes of various sizes is

proportional to the size of the tube. Tubes of smaller size

require less heat to bring the tube to brazing temperature

before adding brazing alloy. Applying too much heat to

any tube can melt the tube. Service personnel must use

the appropriate heat level for the size of the tube being

brazed. Note: The use of a heat shield when brazing is

recommended to avoid burning the serial plate or the finish

on the unit.

1. The ends of the refrigerant lines must be cut square,

deburred, cleaned, and be round and free from nicks or

dents. Any other condition increases the chance of a

refrigerant leak.