Manual

Lubrication

Operating circumstances will dictate

the frequency of required lubrication. It

is highly recommended that the Super

1050 be cleaned and lubed after every

10,000 rounds of operation.

Use a high-grade, conventional

wheel bearing grease – do not use oil.

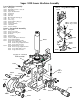

Lubrication Points:

• Casefeed Plunger (#13073*), lube the

sides and bottom.

• Casefeed Plunger Roller (#13498)

and Bolt (#13333)

• Tappet (#12995)

• Rocker Arm (#13058), cam surfaces

and hole.

• Pivot Bolt (#13296)

• Primer Punch Base (#12849 - large or

#13307 - small)

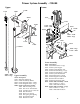

• Lube the Indexing Lever Cam sur-

face (#20312) and Index Lever

Shoulder Bolt (#13276). With the

handle in the rest position, you will

see the Index Roller (#10996) come

into contact with the Lever Cam sur-

face. The Index Roller (#10996) also

requires periodic lubrication.

• Alignment Pins (#12972 & #13515

located under the toolhead)

• Cam Guide Bolt (#12486) and its

mated slot

• Toolhead Bore (#20420 - lightly to

avoid rusting and/or freezing up)

• Mainshaft Lubrication – Use only

30 weight motor oil. DO NOT use a

penetrating lubricant such as WD-

40, Breakfree, etc…

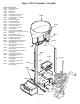

• Swage Connecting Rod (#13417) and

Clevis Pin (#13522)

• Shellplate lock ring (#20311), bottom

surface to shellplate face.

• Shellplate center hole. It’s easiest to

lubricate the shellplate center hole

when changing from one caliber to

another.

We recommend that you use a

droplet of Blue Loctite on the threads of

the following bolts prior to reinstalling:

#13333, #13296, and #13276 (see photos

and schematics).

22

casefeed plunger

(caliber specific)

13498

13333

12995

13296

13058

12849

large

or

13307

small

12486

alignment pin

Super 1050 mainshaft

10999

toolhead bore

alignment

pin

casefeed cam

13417

13522

13276

20312

operating handle shown in

down position

20311