Manual

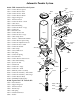

The short end of the ejector wire fits behind the

shellplate bolt (#13328). Note: The correct

positioning of the ejector wire is important or serious

damage to the sizing die could result. See Fig. 14.

Step 3: Changing and Adjusting Dies

Use of Dillon’s Bench Wrench is suggested when

changing or adjusting dies.

Remove screw (#13895) and remove the powder

measure. Remove screws (#13815) and (#14037) and

remove the toolhead assembly. Lift out the three die

inserts (#12864, #11628, #11734) from the frame.

Note: The toolhead you just removed is adjusted for

those dies. Store these parts for when you set up this

caliber again.

Now, take the dies of the caliber that you are

converting to and insert them into the frame,

corresponding to the position reference number on

each die. 1, 3 & 4. If you choose to use the toolhead

you removed, be certain that you back out the

adjustment bolt (#13908) at Station 4 and remove the

seating stem at Station 3.

Reinstall the toolhead with screws (#13815).

Drop the correct powder funnel expander in

the die body (#13865) and mount the powder

measure just as you removed it. Loosen the clamp

screw (#13895).

To achieve proper adjustment of the die it is

important to understand that the adjustable powder

bar should reach the end of its travel at the same

time that the handle reaches the bottom of its stroke

against the frame stops.

To achieve this adjustment, the die body (#13865)

must be screwed up or down. A sized empty shell

case must be placed in the shellplate at Station 2 in

order to check this adjustment. No powder should

be in the measure during these adjustments.

Beware! If you pull the handle and the powder

bar reaches the end of its travel before the handle

reaches the bottom of its stroke, STOP! Raise the die

(#13865) several turns and try again. Once the

adjustment is correct but you want the case mouth

flared a little more, just screw die (#13865) down

1/4 turn or less.

The base of the bullet needs only to set within a

slightly flared case mouth.

Tighten screws (#14037) and (#13895).

Now, you can adjust the powder measure for the

charge your loading data tells you to use. Remember

that the powder charge adjustment screw (#13943)

turns counterclockwise to decrease the volume of

charge and clockwise to increase the charge.

Your conversion kit comes with the seating stems

to fit the most popular bullet styles; wadcutters,

semi-wadcutters and round nose. Choose one and

insert it in Station 3. Simply seat the bullet to a

desired depth. Consult your loading data!

Now, index your seated cartridge to Station 4.

Lower the handle all the way against the frame

stops. Turn the die adjustment bolt (#13908) down

until you feel a slight opposition. Raise the handle

and turn the adjustment bolt clockwise 1/4 to 1/2 a

turn. Insert this cartridge back into the shellplate at

Station 4 and give the handle a full stroke. The

crimping die is now adjusted and you’re ready to

start loading.

Reloading Tips:

If you’re using new unfired brass remove the

sizing die (#12864). Virgin brass usually does not

require full length sizing. (Optional)

Always give the handle a FULL STROKE or

remove all cases and start over, as operations may

be only partially completed.

Use cleaned brass or damage to dies may result.

Avoid the use of military brass with crimped primer

pockets. Crimps can easily be removed with a Dillon

SS-600.

Mount the machine on a sturdy work bench that

will not move while loading. Bench movement will

impair your ability to prime correctly. Suggestion:

Nail or screw your bench directly to your wall.

Keep your machine clean! Read this manual

carefully! If you have any questions please call us!

We’ll help. 1-800-223-4570

NOTICE!

THIS MACHINE IS DESIGNED SPECIFICALLY

TO BE A MANUALLY OPERATED

HANDLOADING MACHINE. ANY ATTEMPTS TO

MECHANIZE THIS PRODUCT WILL VOID ANY

AND ALL WARRANTIES OFFERED BY THE

COMPANY. WE SPECIFICALLY WARN AGAINST

CONVERTING THIS PRODUCT TO AUTOMATED

OR MOTORIZED OPERATION.

All Dillon machines are warranted for life from

defects in material or workmanship, plus a one year

100% warranty against normal wear. All

electrical/electronic components in Dillon

equipment are covered by a one year warranty.

13

Caliber Conversion Chart

Caliber Shellplate Locator Powder

Button Funnel

.45 ACP #1 #1 E

.38/.357 #2 #2 D

.380 Auto #3 #3 F

.44 Mag./Spcl. #4 #4 G

9mm/.38 Super #5 #3 F

.41 Mag. #6 #1 H

.45 LC #C #4 E

10mm #W #2 W