Manual

4.) From this point on, place a bullet on the case at

Station 3 with your left hand. Insert a case at Station

1 with your right hand and cycle the handle. Each

time you cycle the machine a finished round will be

ejected into the cartridge collection bin. (See Fig. 18)

REMEMBER!

Press forward firmly on the handle to seat your

primers. Primer jams or misfeeds can be caused by

misadjustment of the set screw (#13961) in the

primer feed block. The most common case of primer

misfeeds or jams is the primer punch not seating

fully onto the primer slide. This will cause the

primer cup to strike the flexible orifice on the

bottom of the primer magazine tube.

Watch the powder bar function, make sure you’re

getting powder.

Set the bullet straight on the case at Station 3 so

that it enters the die correctly.

Watch your supply of powder and primers,

you’ll be using them faster than you think you are.

Take your time and learn the machine and its

function. The Square Deal “B” will deliver hundreds

of trouble free rounds in short order, just relax and

take your time in the beginning.

Keep it clean – primer residue, spilled powder

and just plain dirt can jam your machine. All

bearing surfaces are Delrin and require no

lubrication.

Clean your powder bar and underneath your

shellplate about every 500 rounds. Some powders

build up and will eventually stick the powder bar.

Paint or lacquer thinner works well to remove any

build up.

Friend at the Factory

We started this manual by saying if you have a

problem, call us. We mean it. Anyone can make a

mistake. There’s no such thing as a dumb question. If

something is giving you a problem, let us help you!

Technical Support & Order Line

1-800-223-4570 FAX (480) 998-2786

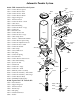

Square Deal “B” Conversion Instructions

Changing calibers on your SDB is a simple

procedure.

First, you must decide whether you need to

change the priming system that is now set up on

your machine. Small calibers use small pistol

primers and large calibers use large pistol primers.

Skip step one if there are no changes needed.

Step 1: Changing The Priming System

Remove Primer Early Warning System. Remove

three screws (#13989 – refer to schematic) to remove

the primer system from the front of the machine.

Remove the primer slide return spring from pin

(#13790) and remove the primer slide assembly from

the magazine system. Replace the correct size

primer slide in the same manner.

IMPORTANT Make sure the magazine is empty

of all primers by inverting the primer assembly.

Remove cap (#13957) and pull out the internal

magazine tube (#13673). Take the correct size

magazine tube and drop a primer, anvil side up, into

the top of the tube to make sure the primer drops

freely through the tube and orifice. Insert the

magazine tube (#13673) into the magazine shield with

the keyed side of the orifice pushed all the way down

into the notch or key way in the housing (#20900).

Replace the cap (#13957). Do not over tighten!

Now, insert a few primers, anvil side up, into the

magazine. Pull the handle, a full stroke, raise the

handle and a primer should appear at Station 2. If a

primer fails to appear, adjust the primer feed

adjustment screw (#13961a), located at the lower tip

of the flat spring (#13979) on the front of the

housing (#20900) as follows:

If changing from a large primer to a small primer

turn the primer feed adjustment scew (#13961a) in

1/8 turn increments clockwise. If changing from

small to large, turn in 1/8 turn increments

counter

clockwise.

Give the handle another full stroke and a primer

should appear. If the primer cup is not centered

under the shellplate or snaps into place when the

handle is raised it may be necessary to adjust the

primer slide travel by turning the slide stop

adjustment screw (#13961b) in 1/8 turn increments.

It is located between the primer slide and the coiled

spring (#13798) on the front on the housing. (See

pages 3 & 4.)

Step 2: Changing Shellplates

Lift out the ejector wire (#13433) and remove

the shellplate bolt (#13328). Carefully remove the

shellplate and be aware of a very small index ball

(#14019) that sits on a spring. Install the correct

shellplate.

12

Fig. 18