User's Manual

Table Of Contents

- Mark III Directional Drilling Locating System

- Table of Contents

- Table of Contents (Cont.)

- Table of Contents (Cont.)

- Safety Precautions and Warnings

- Safety Precautions and Warnings (Continued)

- Dear Customer:

- 3-3000-00b-F.pdf

- 3-3000-00c-F.pdf

- Receiver

- Display Window Icons

- On/Off

- Receiving the Transmitter’s Signals

- Clicking vs. Holding the Trigger

- Changing the Receiver’s Channel Setting

- Changing the Depth Measurement Units (English vs. Metric)

- Battery Status Display for Receiver and Transmitter

- Warning Tones for Transmitter Overheat

- Ultrasonic Function

- Calibrating the Receiver

- Using Depth Antenna Plumb Line to Mark Locate Points

- Finding Firmware Version

- 5.0 Series Firmware Functions

- Receiver

- 3-3000-00d-F.pdf

- 3-3000-00e-F.pdf

- 3-3000-00f-F.pdf

- 3-3000-00g-F.pdf

- 3-3000-00h-F.pdf

- 3-3000-00i-F.pdf

- 3-3000-00j-F.pdf

- Locating

- Locating Mode

- Locate Points (FNLP & RNLP) and Locate Line (PLL)

- Handling the Receiver

- Distance Between FNLP and RNLP Due to Depth, Pitch, and Topography

- Using Plus/Minus Indicators for Locating

- Locating the Transmitter from the Drill

- Locating the Transmitter from the Front

- Method for Confirming Position

- Locating on the Fly

- Off-Track Locating

- Splitting the Front and Rear Negative Locate Points

- Four-Turn Technique

- Calculating Depth Based on Distance Between FNLP & RNLP

- Running off Pitch or Calculating Depth from Pitch

- Transmitter’s Signal Shape

- Antenna Configuration

- Signal Reception

- Front and Rear Negative Locate Points

- Positive Locate Line Above Transmitter

- Locating

- 3-3000-00k-F.pdf

- 3-3000-00l-F.pdf

- 3-3000-00m-F.pdf

- 3-3000-00n-F.pdf

- 3-3000-00o-F.pdf

- 3-3000-00p-F.pdf

®

Remote Display

Remote Steering

Drill

Drill Path

Transmitter

Under

Roadway

Receiver Placed

on Side (Drill

Path Is Aligned

with Target Point

on Front Panel)

Target Point

Setting up DigiTrak Receiver

for Remote Steering

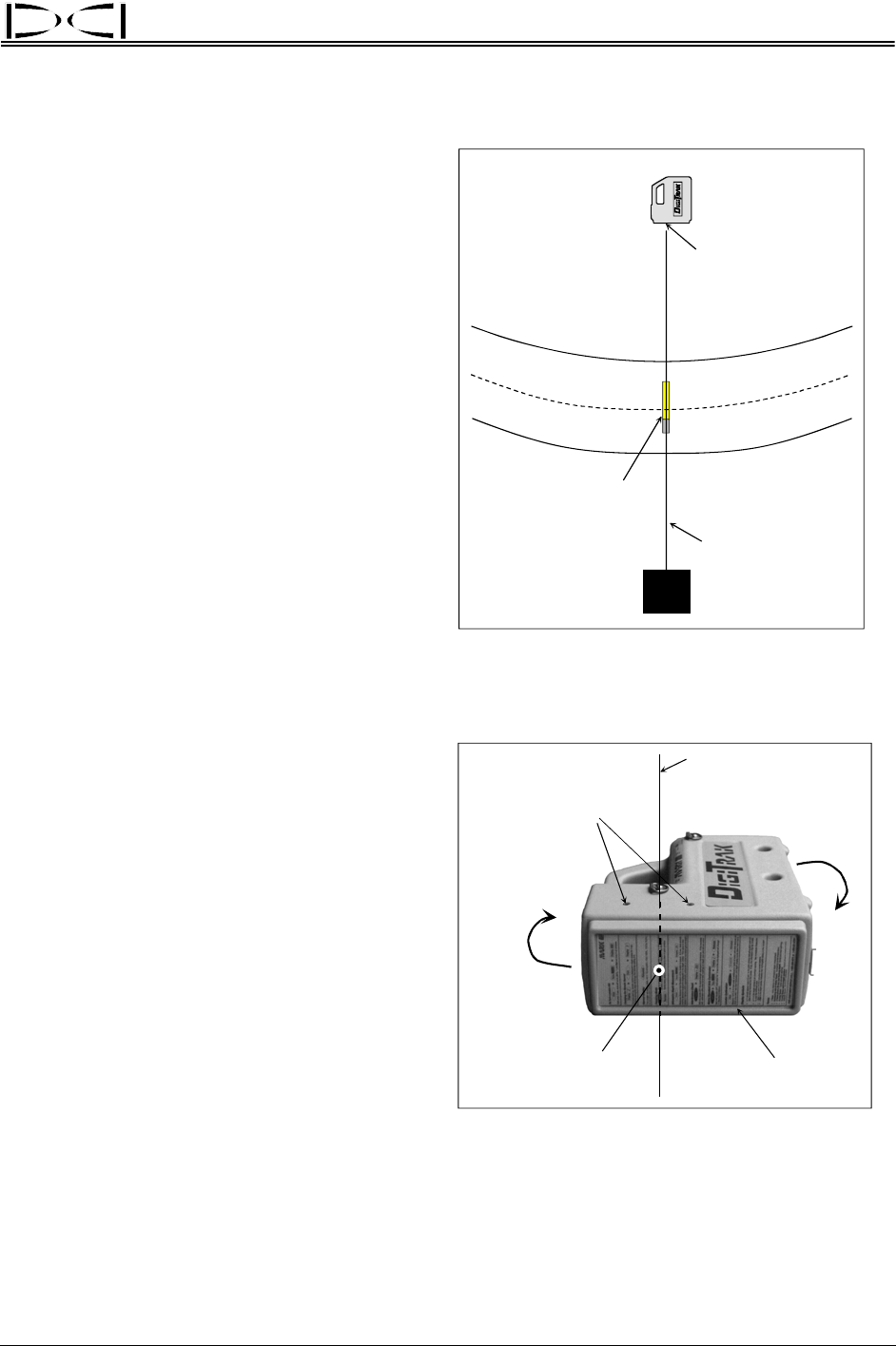

Remote steering is used to cross streams and

roadways or other inaccessible areas when it is

not possible to walk over the transmitter. To

initiate the remote steering capability, the

receiver is placed in front of the transmitter as

the “target.” The distance the receiver can be

placed ahead is limited by the range of the

transmitter and interference.

With the transmitter powered up and in the

housing ready to drill, walk with the receiver

(powered up and trigger held in) on the surface

over the intended borepath to the “target” loca-

tion. Verify that the receiver displays at least

250 points of signal at target location. Place

the receiver on its side so that the orange arrow

on the receiver points toward the ground. The

target point on the receiver is the center point

between the two depth/locating antenna

screws. The receiver’s front panel should face

the drill. To position the receiver properly, it is

important to pivot the receiver using the center

point between the two antenna screws as the

axis of rotation. When the receiver is properly

pivoted on this axis, the vertical bars (indicating

the transmitter’s position) will line up with the

two triangles (indicating the target) in the center

of the remote steering window. When the

receiver is in its target position, its top surface

must be level. If necessary, place shims under

the receiver to level it.

Axis of

Rotation

Depth/Locating

Antenna Screws

Target Point

Front Panel

Using DigiTrak Receiver for Remote Steering

On the remote steering window, the receiver

(target) is represented by two triangles, one

above and one below the window; the

transmitter is represented by a vertical bar in

this window (see photo on next page). If the bar

is to the right of the triangles, the tool will need

to be steered to the left so that the steering indi-

cator is lined up with the triangles; if the bar is to

the left of the triangles, the tool will need to be

steered to the right.

DigiTrak

®

Mark III Operator’s Manual 27