Specifications

Table Of Contents

- About This Manual

- 1.0 Introduction

- 2.0 Installation

- 3.0 Configuration Settings

- 4.0 Calibration

- 5.0 Scale Operations

- 5.1 Weight Unit Switching

- 5.2 Entering Tare Weights

- 5.2.1 One-Touch Tare, Tare Unknown

- 5.2.2 Digital Tare, Tare Weight Known

- 5.2.3 Tare Addition or Subtraction

- 5.2.4 Tare Exchange

- 5.3 Toggling Between Gross and Net

- 5.4 Entering Unit Weights

- 5.4.1 Unit Weight Operation by Sampling

- 5.4.2 Unit Weight Operation by Key Entry

- 5.5 Part Accumulation and Negative Counting - Without Recalling an Item Code

- 5.5.1 Part Accumulation

- 5.5.2 Negative Counting

- 5.5.3 Clearing Accumulated Data

- 5.6 Toggle Between Scales

- 5.7 Adding Parts To and Subtracting Parts From Inventory

- 5.7.1 Adding Parts to Inventory

- 5.7.2 Subtracting Parts From Inventory

- 5.7.3 Sample, Count and Print a Label

- 5.7.4 Scan ID Bar Code, Count and Print a Label

- 6.0 Scale Programming

- 6.1 Item Code Storage

- 6.1.1 Checking Memory Status

- 6.1.2 Program ID Code, Unit Weight, Tare Weight, Label Format, Part Name, Part Number, Lot Number, Location, Inventory Quantity, Threshold, and Setpoints

- 6.1.3 Delete Item Memory

- 6.2 Using Item Codes in Normal or Operation Mode

- 6.2.1 Recalling Numeric Item Codes using Item Code Number

- 6.2.2 Re-Computing Item Code Unit Weight

- 6.2.3 Quick Add Item to Memory

- 6.2.4 Tare Override

- 6.2.5 Inventory Operations Related to the Item Code Quantity

- 6.2.6 Delete Item Memory

- 6.3 Setting Tare in Operation Mode

- 6.3.1 One Touch Tare

- 6.3.2 Digital Tare (When Tare Weight is Known in Advance)

- 6.3.3 Tare Value Exchange (Tare Addition or Subtraction)

- 6.4 Setting a Lot Number

- 6.5 Setting a Sequence Number

- 7.0 External Printers, Barcode Scanners, Keyboards and Platforms

- 7.1 Connecting External Printers

- 7.1.1 SPEC Settings for External Printers

- 7.1.2 Connecting the Printer to the RS-232C Port

- 7.1.3 Eltron Printers

- 7.1.4 Epson Printers

- 7.2 Connecting a Barcode Scanner

- 7.2.1 Header Codes

- 7.2.2 Z Commands via Barcodes

- 7.2.3 Configuring the RS232C Port for a Scanner

- 7.2.4 Connecting the Scanner to the RS232C Port

- 7.2.5 Configuring the Keyboard Port for a Scanner

- 7.2.6 Programming the QSC-6000 Plus Quickscan RS232C Scanner

- 7.2.7 Programming the QuickScan Keyboard Wedge Scanner

- 7.3 Connecting the IBM Keyboard

- 7.4 Connecting an External Platform

- 8.0 Job Sequence Programming

- 9.0 Password Protecting the Programming Functions

- 10.0 DC-100 Error Message List

- 11.0 DC-100 Limited Warranty

6 DC-100 Operation Manual

.

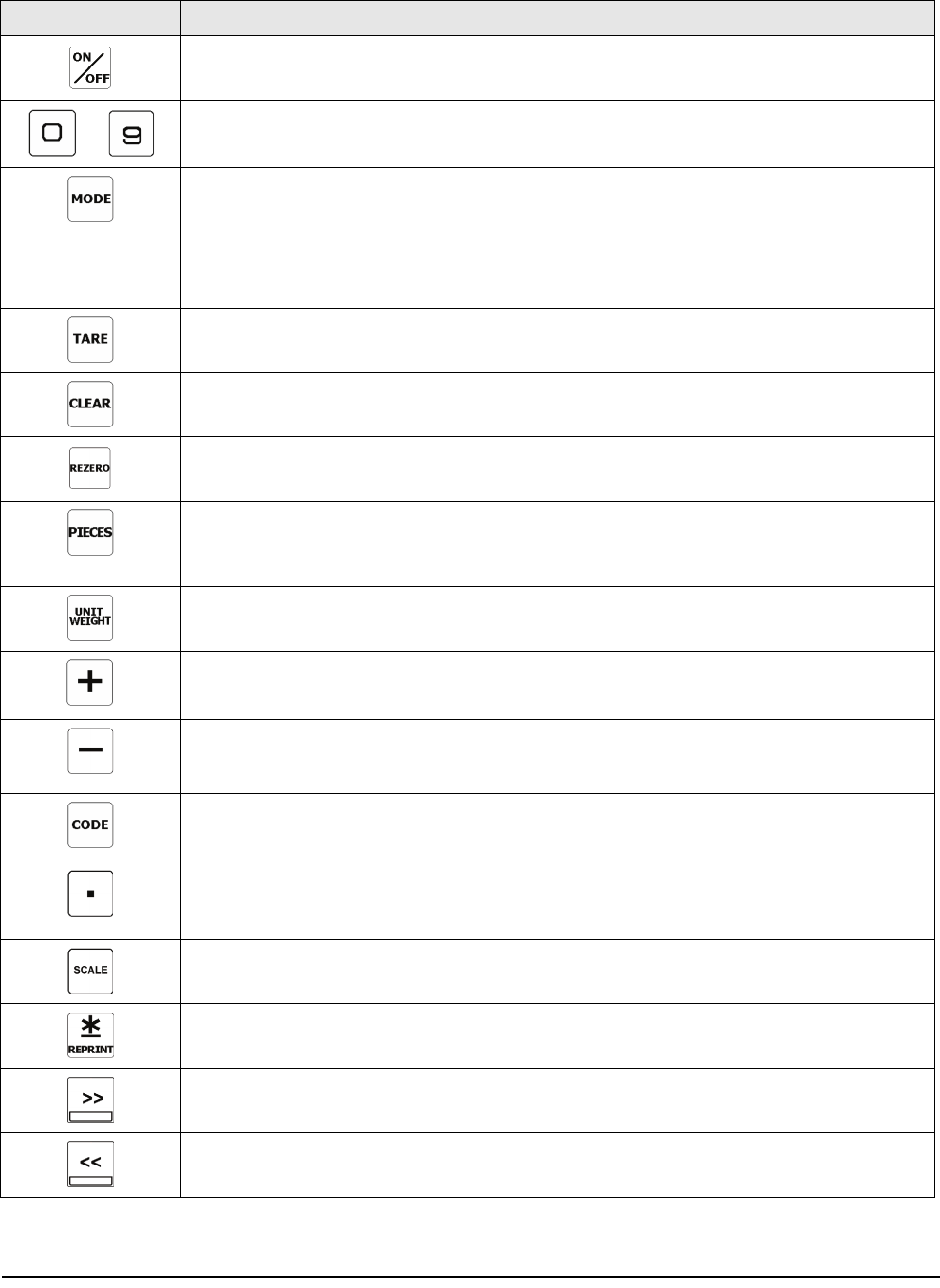

Key Description

Turns the scale display on or off

Used to enter numeric values. When using the scale, first enter a numeric value, then press the

appropriate function key.

Allows cycling between the different modes:

• Operation Mode – weighing and counting operations

• Report Mode – this mode is not used with the DC-100

• Program Mode – entering item data, factory name

• Password Mode – password protecting certain operations

• Service Mode -setup and troubleshooting by an authorized dealer or technician

• Operation Mode – set and clear tare weights

• Other Modes – used to select “No”

• Operation Mode – clear keyed-in data from the display starting with the last digit entered

• Other Modes – used to select “Yes”

Used to reset the scale to zero. Also used in conjunction with other keys to enter the maintenance

mode. The REZERO key does not function when the scale is in motion.

• Operation Mode - compute unit weight by sampling. Press the PIECES key after placing a sample

on the platform, or after using the numeric keypad to enter the sample size. On multi-channel

units, ensure that the correct scale is selected.

• Other Modes - escape the programming screen without saving data

Used to enter a known unit weight using the numeric keypad

• Program Mode – select an item to be programmed such as item code, factory name, or cycle

through set-point modes

• SPEC Setting – move between SPEC numbers (low to high)

• Program Mode –- select programming item such as item code, factory name

• Other Modes – enter the delete function

• SPEC Setting – move between SPEC numbers (high to low)

• Operation Mode – call up stored item code information and switch between item code inventory

IN and OUT modes

• Program Mode – store the programmed data

Enter numeric values containing a decimal point

Note: A numeric value must be entered before the decimal point. For example, .250 would be

entered as 0.250.

Cycle between Scales A through D when using the DC-100 as a multi-scale system.

• Operation Mode – print a label or report

• Program Mode – enter information about an item into temporary memory

Move the cursor. Change the entry to the right. Also used to cycle forward between choices in SPEC

setting mode.

Move the cursor. Change the entry to the left. Also used to cycle backward between choices in

SPEC setting mode.

Table 1-5. DC-100 Key Functions

to