Technical data

81

Version 250

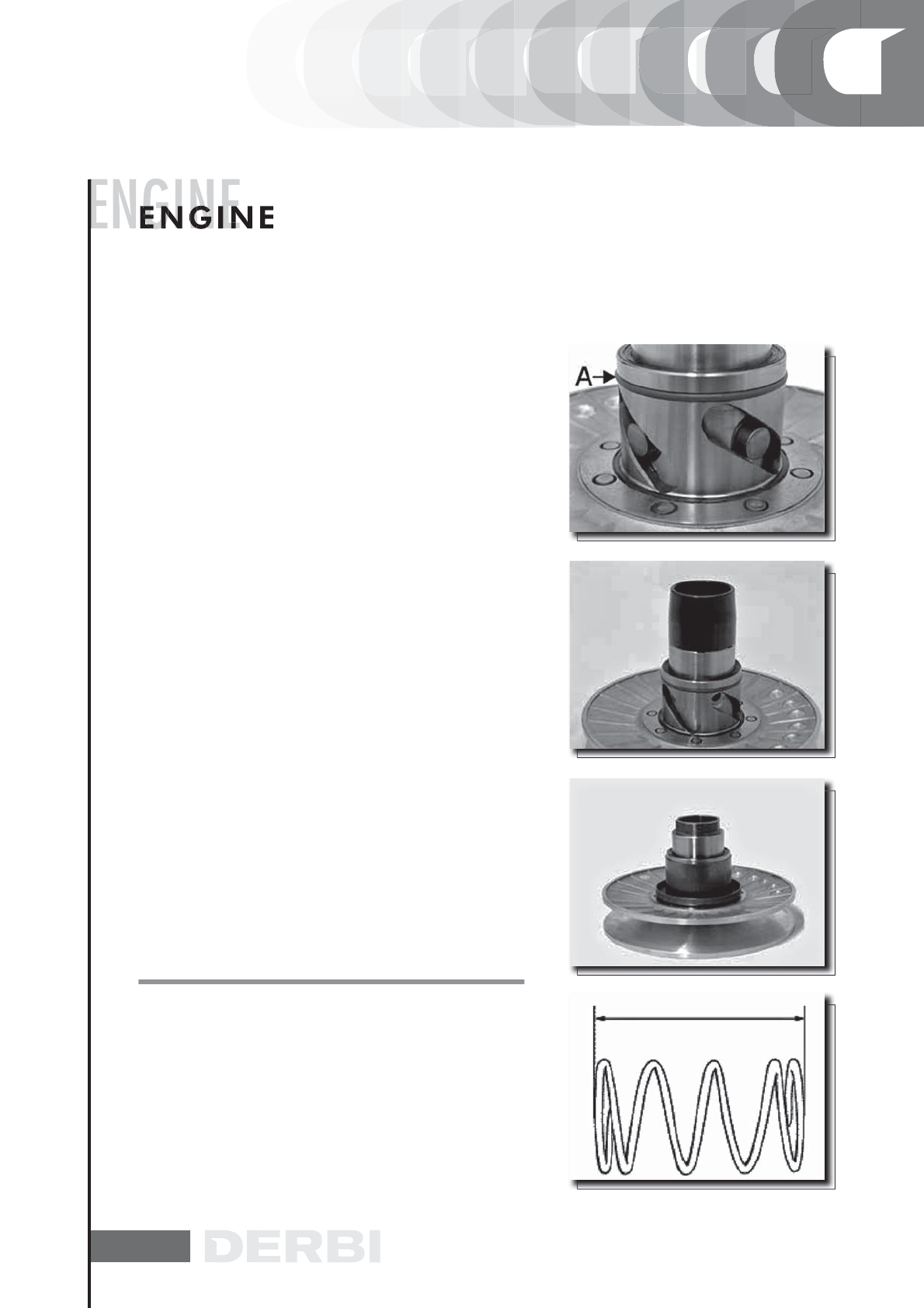

- Insert the new oil guards and O-Rings on the mobile half-

pulley.

- Slightly grease the O-Ring «A» shown in the figure.

- Install the half pulley on the bushing using thespecific tool.

- Check that the pins are free from wear and reassemble into

the relative slits.

- Replace the collar to close the servo-system.

- Using a bent beak greaser, lubricate the driven pulley unit

with about 6 gr. of grease, this operation should be carried

out through one of the two holes into the bushing to obtain

the exit of the grease from the opposite hole.

This operation is required to prevent the presence of grease

beyond the O-rings.

N.B.

THE SERVO-SYSTEM MAY BE LUBRICATED BOTH WITH BEA-

RINGS MOUNTED OR UPON THEIR REPLACEMENT; THE IN-

TERVENTION CARRIED OUT DURING THE BEARING OVER-

HAULING MAY BE EASIER

Specific tooling

020263Y Protective sheath

Recommended products

Grease for the phonic wheel turning ring

Molybdenum disulphide grease and lithium soap

INSPECTING THE CLUTCH SPRING

Version 250

- Measure the free length of the mobile driven half-pulley

spring.

Characteristic

Standard length (125)

106mm

Limit after use (125)

101 mm

Standard length (200 - 250)

123 mm

Limit after use (200 - 250)

118 mm

SC G CUC SG