Technical data

79

- Check that the surface of contact with the belt does not

show abnormal wear.

- Check the functionality of the riveting.

- Check the planarity of the belt surface of contact.

REFITTING THE DRIVEN HALF-PULLEY BEARING

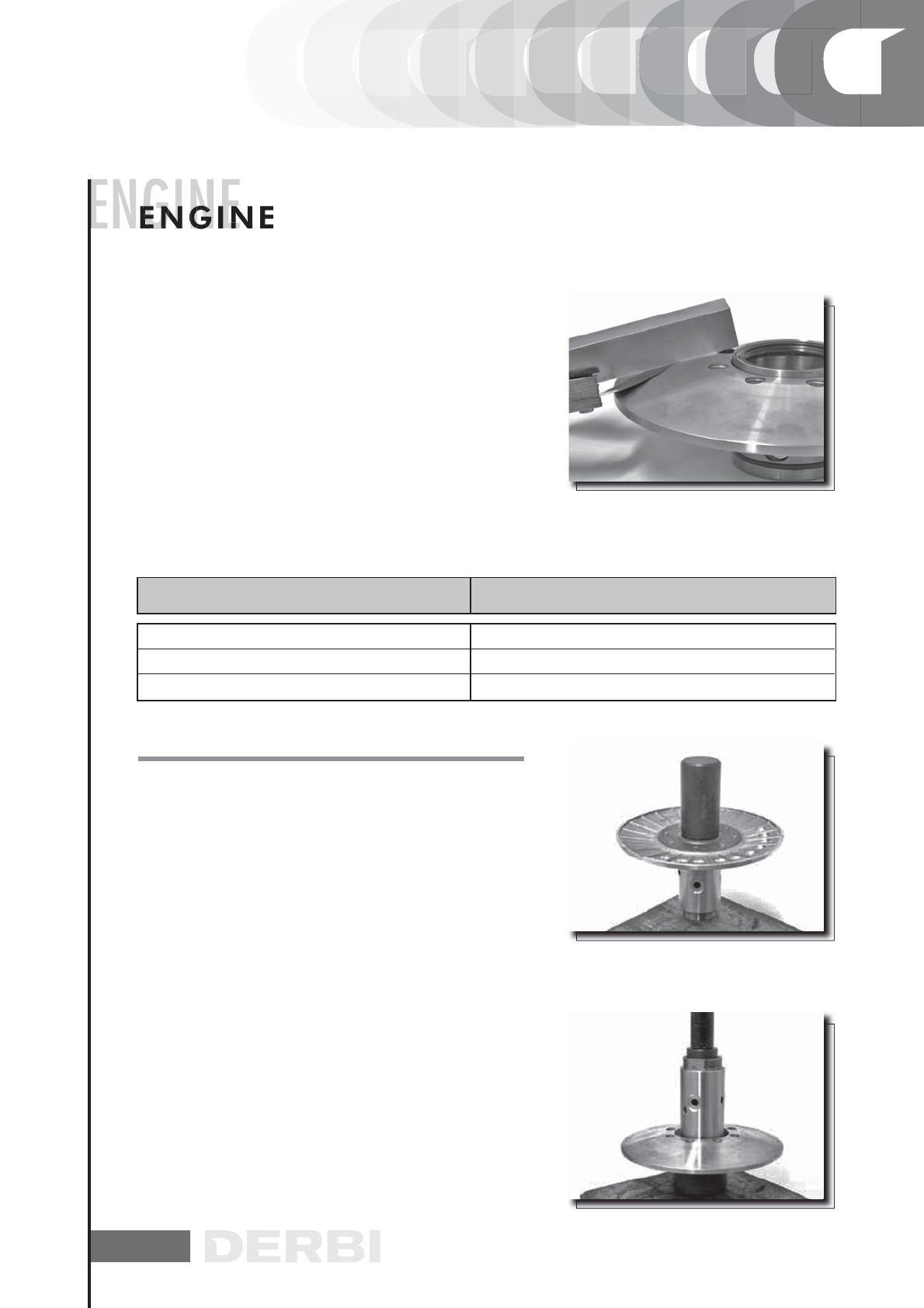

- Suitably support the pulley bushing from the threaded side

on a wooden surface.

- Install a new roller casing as shown in the figure.

- To install the new ball bearing, proceed as shown in the

figure using the modular punch.

- Install the lock ring

N.B.

INSTALL THE BEARING WITH VISIBLE SCREENING.

Specific tooling

020376Y Handle for punches

020375Y Adapter 28 x 30 mm

020424Y Driven pulley roller casing drift

MOBILE LINE HALF PULLEY DIMENSIONS

SPECIFICATION DESC./QUANTITY

Wear limit

Standard diameter

Maximum admissible diameter

0,3 mm

Ø 41,000 + 41,035

0 41,08 mm