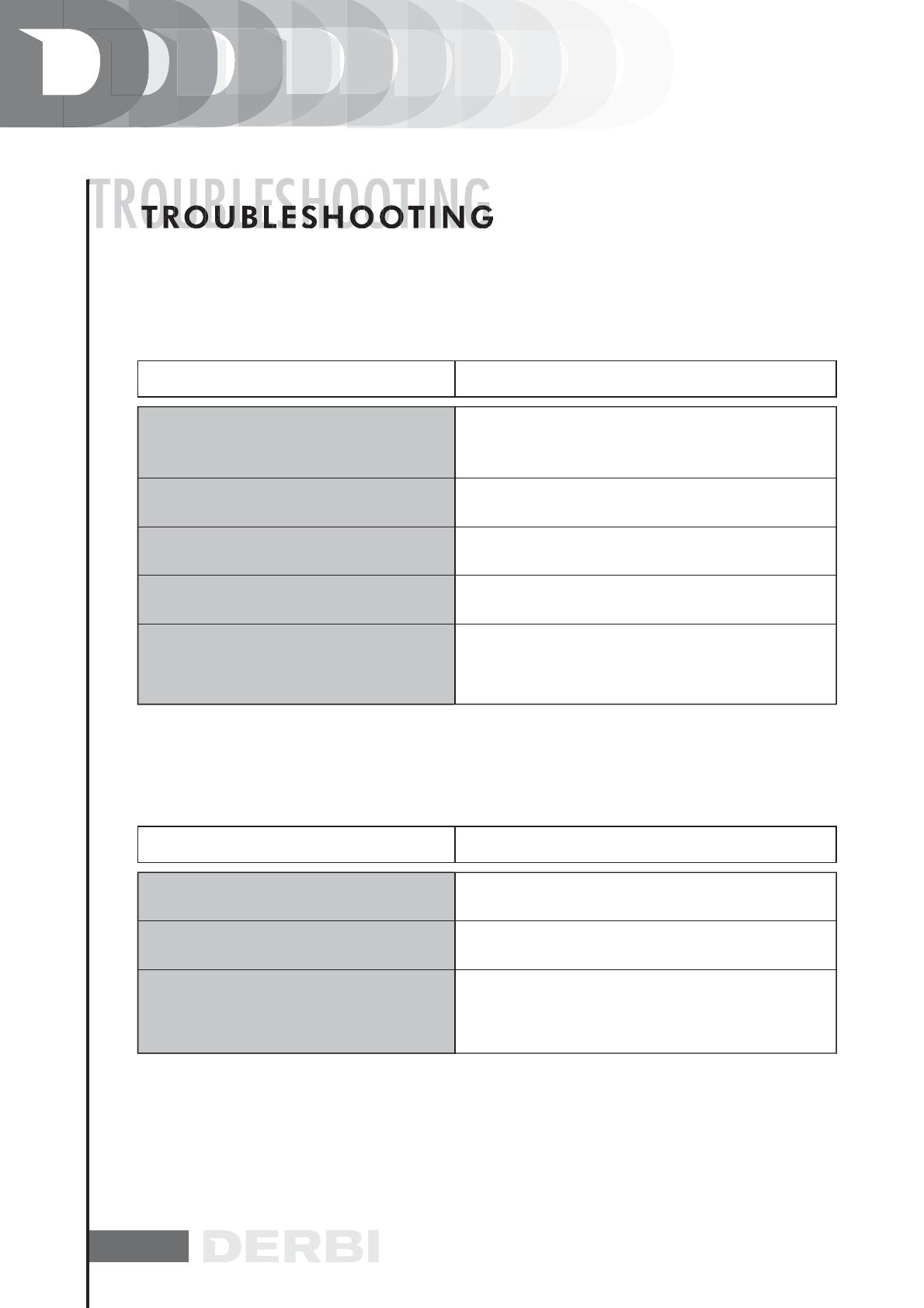

Technical data

240

POSSIBLE CAUSE

WORK

Float level Restore the level in the basin by bending the fuel inlet

pin thrusting reed on the float so as to have the float

parallel to the basin plane with upturned carburettor.

HIGH FUEL CONSUMPTION

H

IGH CONSUMPTION

Slackened nozzles Check the maximum and minimum nozzle locking into

their seat

Fuel pump failure Check that there is no fuel in the vacuum duct.

Inefficient starter Check: electric connections, circuit continuity, mecha-

nical sliding, and presence of power

Air filter clogged or dirty Remove the sponge, wash with water and shampoo,

then impregnate it in a 50% mixture of fuel and speci-

fic oil, the’n press it without squeezing, let it drip arrd

replace it.

POSSIBLE CAUSE

WORK

EXCESSIVE EXHAUST NOISE

E

XCESSIVE NOISE WITH EXHAUST

Cut-off valve of the secondary air device

does not work

Replace the secondary air device

Pressure inlet pipe from the secondary air

device disconnected or cracked

Replace the pipe

Reed valve of the secondary air device does

not close properly and deteriorates the rub-

ber coupling between the device and the

head pipe.

Replace the device and coupling