Technical data

148

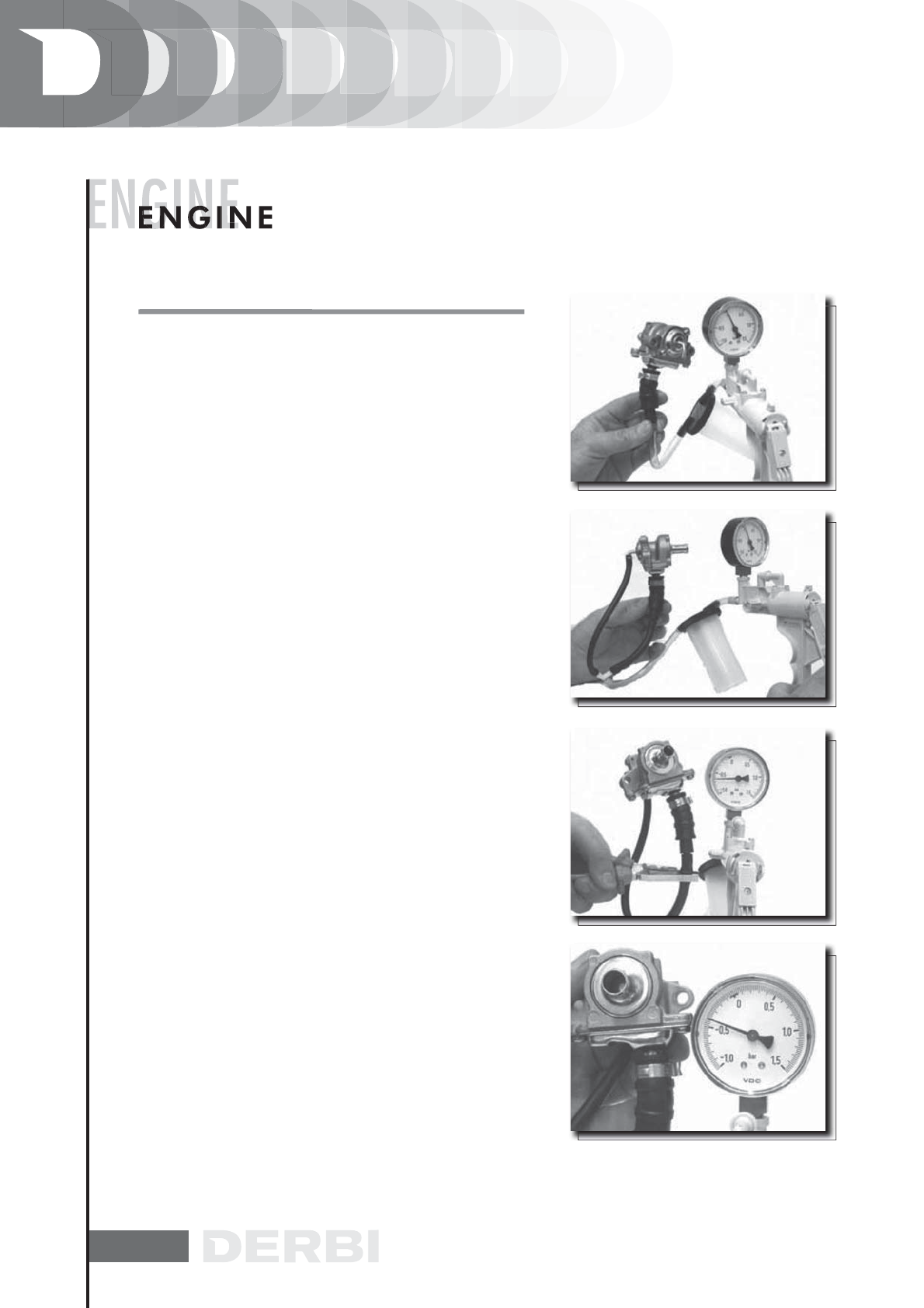

INSPECTING THE CUT-OFF

- Remove the SAS valve

- Connect the pump in vacuum position (VACUUM) to the

CUT - OFF valve vacuum inlet

- Apply a vacuum of over 0.5 BAR

- Check that this value is maintained over time

- If the value is not maintained, proceed to replace

- Using a «T» branch and rubber hoses, implement a parallel

connection between the rubber sleeve and the vacuum inlet

of the CUT - OFF valve

- Connect the branch to the ^SlQgWfSK, pump

- Set the pump in vacuum position (VACUUM)

- Using pliers with flat and long tips, temporarily clamp the

rubber hose in the proximity of the valve

- Command the pump to create a vacuum of over 0.5 BAR

- Release the hose and check the vacuum behaviour

- In normal operating conditions, the vacuum undergoes a

drop and then settles. Then there occurs a gradual and slow

depression up to the value of about 0.4 BAR. At this point,

the valve opens and vacuum suddenly resets. A seal failure

or opening at different vacuum values are abnormal. Pro-

ceed to the replacement.

N.B.

BESIDES IMPAIRING THE FUNCTIONALITY OF THE CUT - OFF,

AN INCORRECT SEAL OF THE CUT-OFF VALVE MEMBRANE

AFFECTS THE IDLE OPERATION.

N.B.

A SEAL FAILURE OF THE CUT - OFF VALVE CAUSES EXHAUST

NOISE (EXPLOSIONS IN THE SILENCER). A WRONG CALIBRA-

TION OF THE CUT

- OFF VALVE CAN IMPAIR THE CORRECT FUNCTIONALITY OF

THE CATALYTIC CONVERTER.

Specific tooling

020329Y Pump

INSPECTING THE CUT OFF