Technical data

135

N.B.

THE HEAD LUBRICATION CHANNEL IS PROVIDED WITH A

SHUTTER JET; THIS GIVES A «LOW PRESSURE» HEAD LUBRI-

CATION; THIS CHOICE WAS MADE TO REDUCE THE OIL TEM-

PERATURE IN THE SUMP. THE JET CLOGGING IMPAIRS THE

HEAD LUBRICATION AND THE TIMING MECHANISMS. A JET

FAILURE CAUSES A DECREASE OF THE BENCH BRASS AND

CONNECTING ROD LUBRICATION PRESSURE.

N.B.

THE JET IS FED THROUGH THE BENCH BRASSES. PROPER OPE-

RATION OF THIS COMPONENT IMPROVES THE PISTON TOP

COOLING. CLOGGING HAS EFFECTS THAT ARE DIFFICULT

TO DETECT (PISTON TEMPERATURE INCREASE). FAILURE OR

LEAK CAN CONSIDERABLY DECREASE THE BENCH BRASS

AND CONNECTING ROD LUBRICATION PRESSURE.

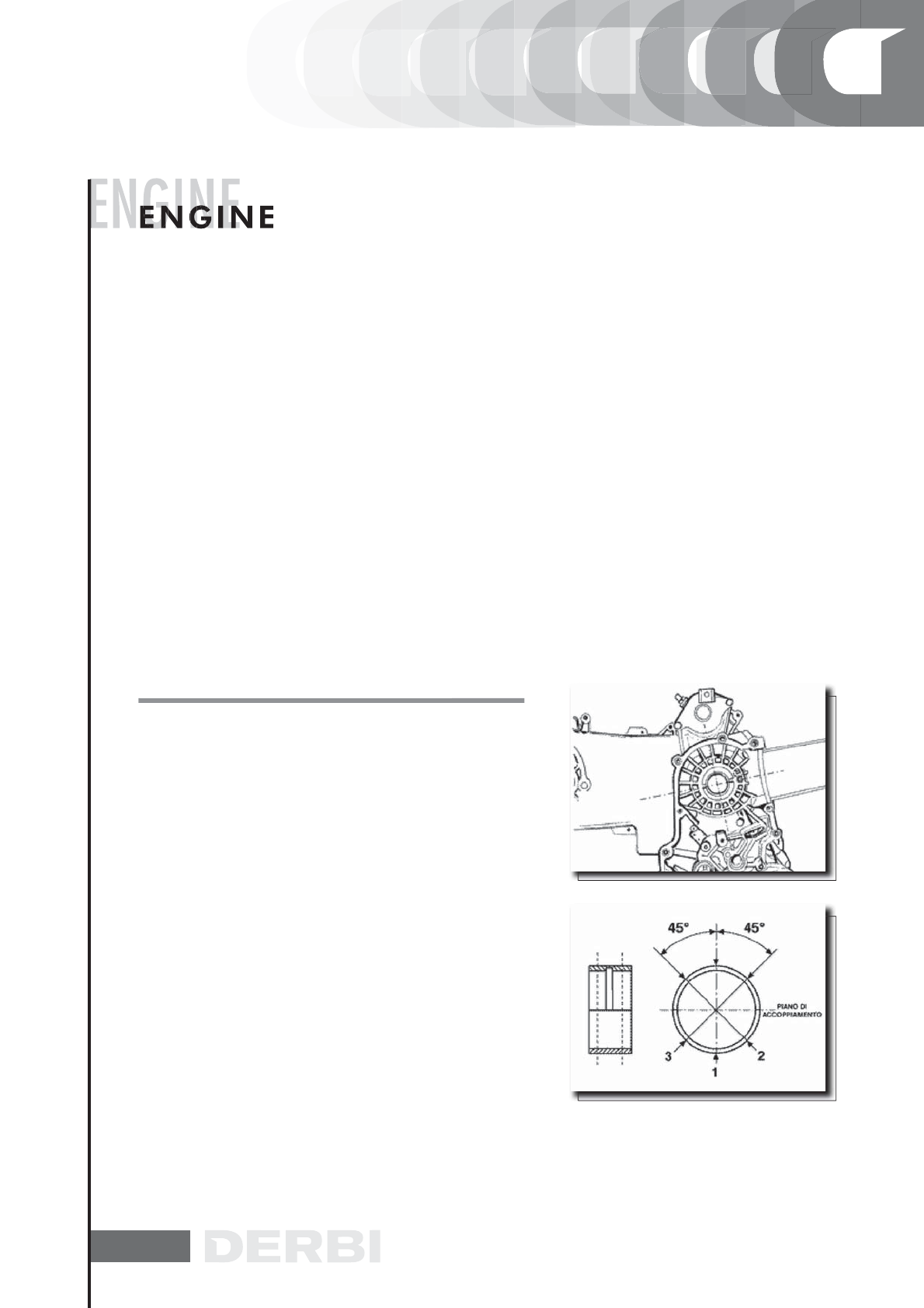

INSPECTING THE CRANKSHAFT PLAIN BEARINGS

- To obtain a proper lubrication of the brasses, it is neces-

sary to have an optimum lubrication pressure (3,2 bar) and

a good oil rate; to this purpose, the brasses must be placed

properly, so as to not have shuttering in the oil feeding chan-

nels.

- Bench brasses are realised with 2 half-bearings, one of

which is solid while the other has holes and seats for lubri-

cation.

- The solid half-bearing is intended to stand the thrusts cau-

sed by combustion, and for this reason it is arranged oppo-

sed the cylinder.

- To prevent shutters in the oil feeding channels, the mat-

ching surface of the two half-bearings must be perfectly or-

thogonal to the cylinder axis, as shown in the figure.

- The oil feeding channel section is also affected by the brass

driving depth relative to the driving shaft axial clearance

containment plane.

- Check the brass diameter in the 3 directions shown in the

figure.

- Repeat the measurements for the other half of the brass.

See figure.

- The crankcase is supplied in three setup versions: with RED

brasses, with BLUE brasses and with YELLOW brasses.

SC G CS GS