Technical data

133

Characteristic

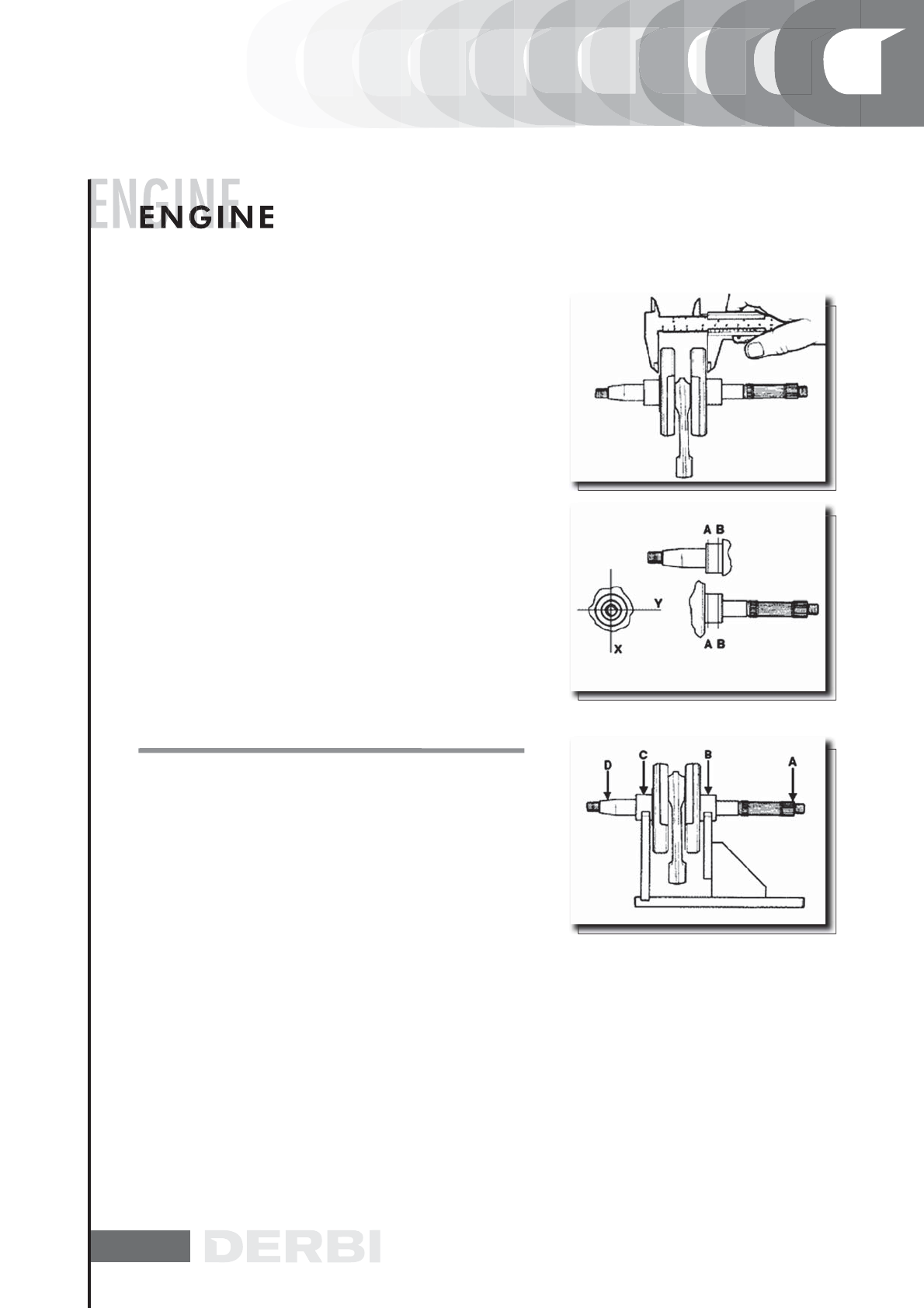

Driving shaft - case axial clearance:

Standard clearance 0,15 ÷ 0,40 mm

Driving shaft - connecting rod axial clearance:

Standard clearance 0,20 ÷ 0,50 mm

Driving shaft - connecting rod radial clear-ance:

Standard clearance 0,036 ÷ 0,054 mm

Driving shaft width with complete washers standard measurements

55,67 ÷ 55,85 mm

Driving shaft capacities:

Standard diameter: cat1 - 28,994 ÷ 29,000

Driving shaft capacities:

Standard diameter: cat 2 - 29,000 ÷ 29,006

INSPECTING THE CRANKSHAFT ALIGNMENT

To install the drive shaft on the support and to measure the

misalignment in the 4 points indicate to you in figure.

- Check that the driving shaft cone, the tab seat, the oil guard

connection and the threaded tangs are in good working or-

der.

- In case of failures, replace the driving shaft. The connecting

rod head brasses cannot be replaced.

For the same reason, when cleaning the driving shaft, be

careful to prevent any impurity from entering into the shaft

lubrication hole.

In order to prevent damaging the connecting rod brasses, do

not attempt cleaning the lubrication duct with compressed

air.

- Make sure that the 2 pads on the crank button are properly

mounted.

- A wrong installation of a pad can seriously affect the brass

lubrication pressure.

INSPECTING THE CRANKSHAFT ALIGNMENT