Technical data

132

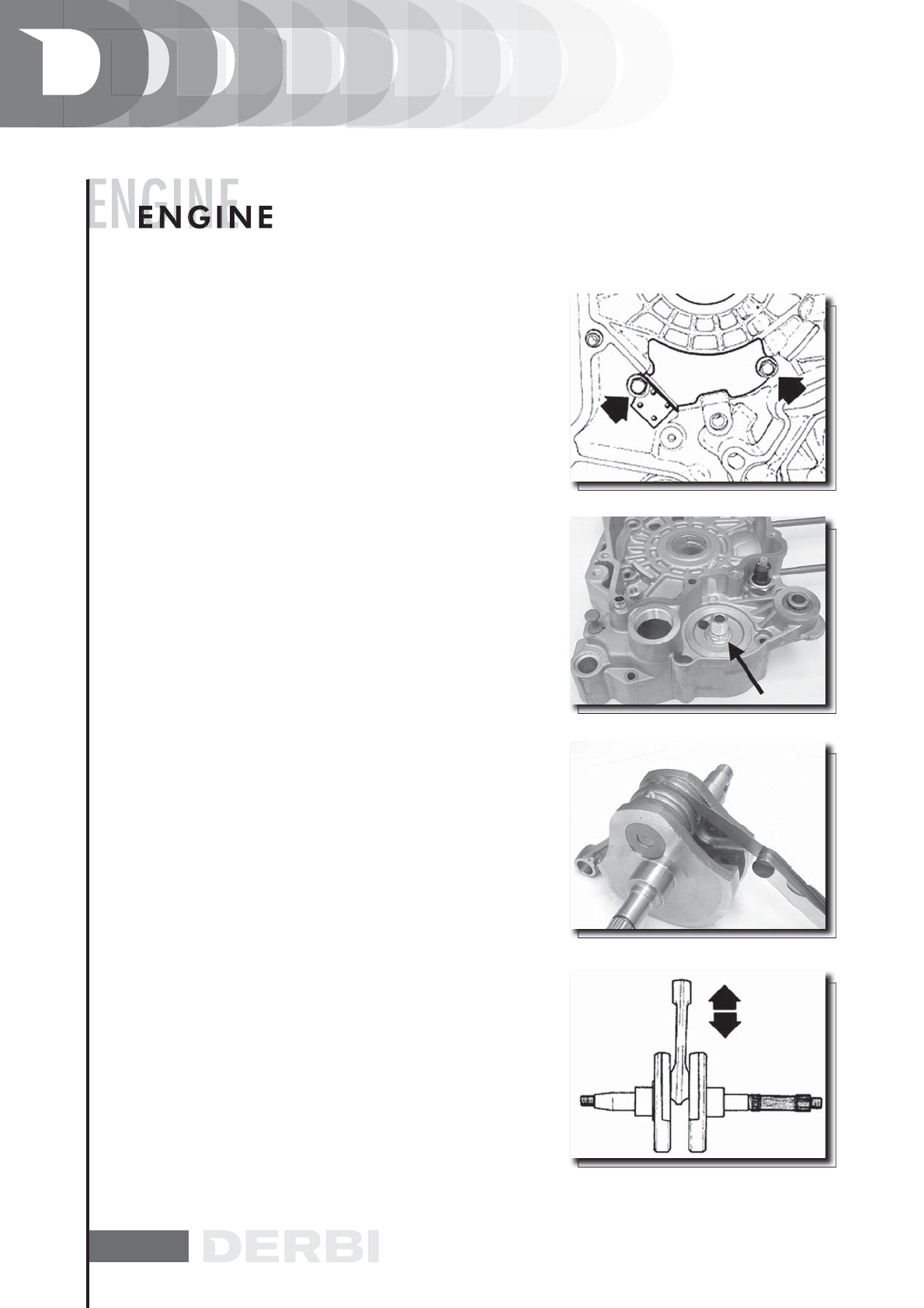

- Check the axial clearance of the connecting rod.

- Check the radial clearance of the connecting rod.

- Check that the axial clearance containment surfaces do

not show scoring and using a gauge, check the width of the

driving shaft as shown in the figure.

- If the driving shaft-case axial clearance is greater than the

standard and the driving shaft does not show any abnorma-

lity, the problem is surely due to wear or incorrect machining

of the engine case.

- Check the diameters of both capacities of the driving shaft

according to the axes and planes shown in the figure. The

shaft sections are classified in two categories, Cat. 1 and

Cat. 2 shown beneath in the table.

CAUTION

BE CAREFUL NOT TO LET THE MEASUREMENT BE AFFECTED

BY THE UNIONS WITH THE DRIVING SHAFT ENDS.

CAUTION

WHILE OPENING THE CRANKCASES AND REMOVING THE

DRIVING SHAFT, CHECK THAT THE SHAFT THREADED ENDS

DO NOT INTERFERE WITH THE BENCH BRASSES. FAILURE

TO OBSERVE THIS PRECAUTION CAN DAMAGE THE BENCH

BRASSES.

CAUTION

FAILURE TO OBSERVE THIS RULE CAN CAUSE THE ACCIDEN-

TAL DROP OF THE DRIVING SHAFT.

N.B.

THE DRIVING SHAFT CAN BE REUSED WHEN THE WIDTH FA-

LLS WITHIN THE STANDARD VALUES AND THE SURFACES ARE

FREE FROM SCRATCHES.

Specific tooling

020262Y Crankcase detachment plate

020335Y Magnetic stand and comparator