Operation Manual

60

De Dietrich Gas 310/610 ECO

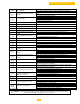

Fan not operating

- Fan defective

- Fan cable is corroded, resulting in absence of voltage or control signal.

Fan operates continuously or signal

incorrect

- Check the fan cable connectors on both the fan and the automatic burner unit

side.

- Fan electronics defective

- Excessive negative chimney pressure

Max ΔT exceeded

Check;

- Flow

- System as has proper air elimination

- Water pressure in the system

Temperature sensor fault Short circuit of flow temperature sensor

Temperature sensor fault Short circuit of return temperature sensor

Temperature sensor fault Short circuit of flue gas temperature sensor

Temperature sensor fault Flow temperature sensor not connected or defective

Temperature sensor fault Return temperature sensor not connected or defective

Air pressure differential sensor short

circuited

- Check the connecting cable of the air pressure differential sensor

- Air pressure differential sensor is defective or not connected

Air pressure differential sensor open

- Check the air pressure differential sensor connecting cable for short circuiting,

etc.

- Air pressure differential sensor is defective

Temperature sensor fault Flue gas temperature sensor not connected or defective

one or more parameters are out of limits The input of the parameter(s) are incorrect

Hydraulic pressure sensor short circuited

- Check the hydraulic pressure sensor connecting cable for short circuit, etc...

- Hydraulic pressure sensor is defective

Hydraulic pressure sensor open

- Check connecting cable of the hydraulic pressure sensor for short circuit, etc...

- The hydraulic pressure sensor is defective or not connected

Maximum flue gas temperature

exceeded

Check the heat exchanger for fouling on the flue gas side

Air pressure differential sensor not

opening

Check;

- Is the air pressure differential sensor defective

- Has the wiring been short circuited

- Excessive positive chimney pressure

Weak flame ionization signal during

operation (after 4 restarts during 1 heat

demand)

- Flue gas recirculation, check venting & heat exchanger for leaks

- Insufficient air flow due to blockage

- Check the boiler settings

Boiler block temperature too high

Check; The heating pump is operating

- There is sufficient water flow through the boiler

- The water pressure is > 11 psi or 0.8 bar

Gas leak VA1 (optional)

The VPS gas leakage control has detected a leak, Check for external leaks,

otherwise replace gas valve multiblock

Gas leak VA2 (optional)

The VPS gas leakage control has detected a leak, Check for external leaks,

otherwise replace gas valve multiblock

Air pressure differential sensor fault

Air pressure differential sensor fault during pre-purge (after 4 restarts)

Check; Is the air pressure differential sensor defective

- Has the wiring short circuited

- Excessive high positive chimney pressure

Boiler block temperature > flow

temperature + hysteresis

Check; - The heating pump is operating

- There is sufficient water flow through the boiler

- The water pressure is < 11 psi or 0.8 bar

Temperature sensor fault Short circuit of boiler block sensor

Temperature sensor fault Boiler shut-off sensor is not connected or defective

Boiler block temperature too high

Check; - The heating pump is operating

- There is sufficient water flow through the boiler

- The water pressure is < 11 psi or 0.8 bar

other

codes

Control unit has internal fault

Proceed as follows with all non-listed codes

- Press the reset button once

- Check that the wiring is not short circuited

- If the fault persists, contact our service department

Table 23 Failure codes

WARNING!! Do not reset the boiler control until you can identify and have resolved the problem. Unresolved problems

could cause personal injury or damage to the boiler and controls.