Product Manual

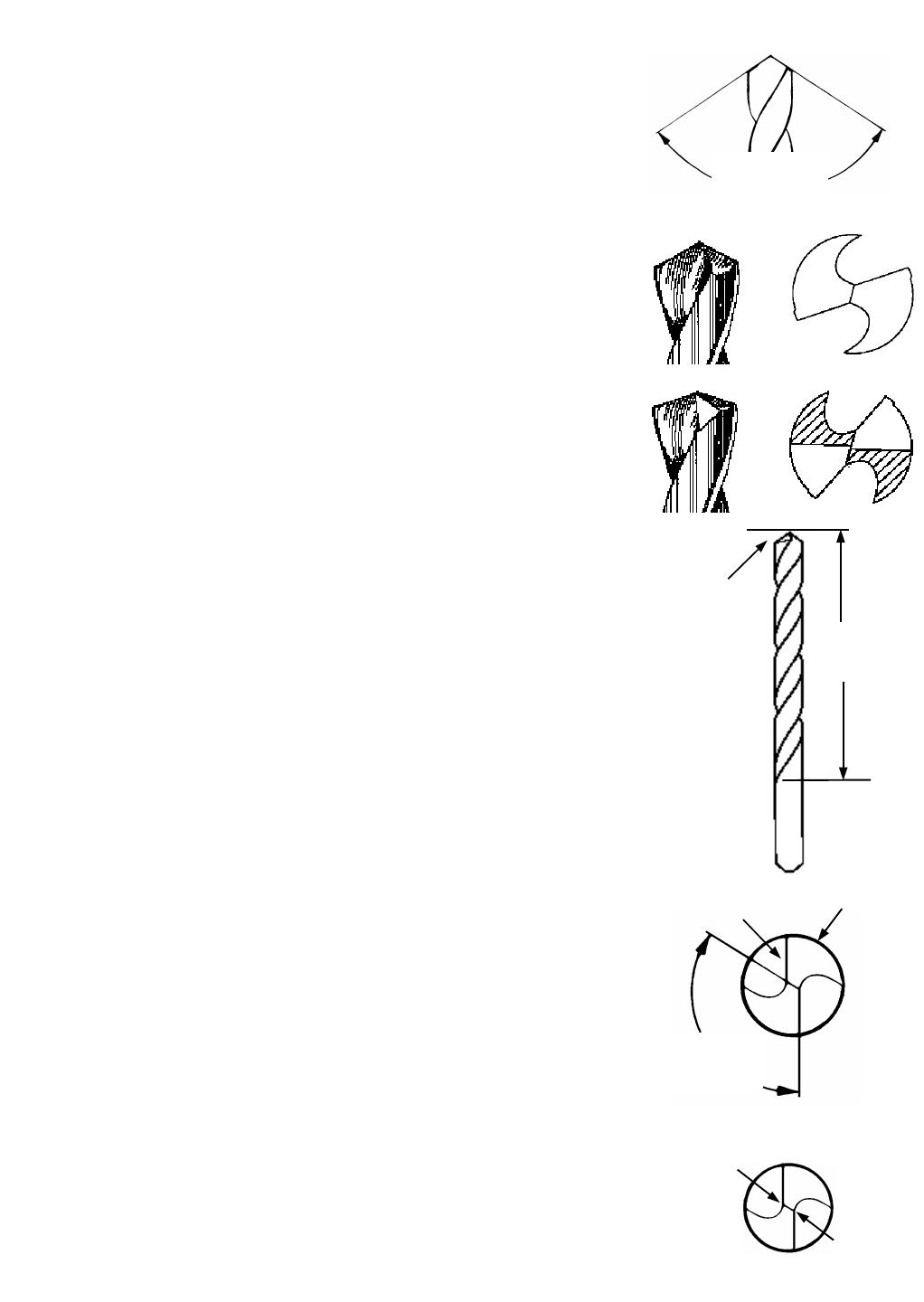

118º STANDARD POINT: This drill bit point angle is considered a

standard general-purpose geometry. It is used for drilling soft or mild

materials such as cold rolled steel, aluminum, and wood. Typically the

standard drill bit is made of High Speed Steel (HSS). The tip of the

drill bit can easily be split making it a high performance drill bit.

135º HIGH PERFORMANCE SPLIT-POINT: The flatter point angle of this

drill is designed for harder, tougher materials such as tempered steels,

hard alloys or hard cast metals. Due to the thicker web and flat point

angle this drill point works best when its split-point is maintained.

SPLIT POINTS: Split point drill bits do not walk around on the material

before they begin to cut. This feature is described as self-centering.

Center punching or center drilling is often eliminated. A standard drill

bit chisel point has to wear an area in the middle of the hole prior to

the cutting lips removing material. Due to its additional cutting lips

along the chisel edge, a split point will begin cutting immediately. Much

less thrust is required to drill a hole with a split point as compared to a

non-split or conventional point. You can split either the 118º or the

135º degree points on this DAREX V390 precision Drill Sharpener.

CARBIDE DRILL BITS: This point angle is typically 130º to 135º.

Carbide is harder and more brittle than high speed steel and cobalt.

This type of drill is used for drilling tempered steels, alloys, glass, etc..

With an optional diamond wheel carbide drill bits can be sharpened on

your DAREX V390 Drill Sharpener equipped with an optional diamond

wheel.

PARABOLIC AND COBALT DRILL BITS: These drills have a thicker web

than regular drill bits. Parabolic drill bits are designed to drill deep

holes. Cobalt drill bits are for drilling tougher metals. They are extra

thick in the center, (web) and have split points. Often these bits are

Titanium Nitride coated. TiN is applied to increase a drill bits cutting

efficiency. Most of these drill bits can be sharpened with your DAREX

V390 Drill Sharpener.

LIP RELIEF ANGLE: The relief on a drill bit is the downward angle

between the cutting lips (leading edge) and the heel (trailing edge) on

the drill point. If the drill bit cutting lips are not higher than the heel,

then the drill bit will not cut into the material. This is often referred to

as negative relief (see page 6). The DAREX V390 Drill Sharpener is

designed to grind a standard factory relief on your drill bits.

CHISEL EDGE ANGLE: The chisel edge is the line across the point of a

drill bit. Note that in the drawing (seen at right) the chisel edge angle

is between 120º and 135º . Another way to look at this is to imagine

the drill point as a clock face. With the cutting lips horizontal, the chisel

edge should point to the 1 and 7 o’clock positions. This is the most

common drill bit chisel angle.

WEB: The web is the core thickness of a drill point. A new drill is

typically around 18% of the drill bit diameter. As a drill bit is sharpened

and becomes shorter the web thickness will increase. Splitting the point

or thinning the web on a drill bit will maintain drill bit performance.

118

135

Web

Flute

Length

Lip Relief

Angle

8 to 12

Heel

Cutting Lip

120 to 135 Chisel

Edge Angle

Included Point

Angle

Drill Information