Product Manual

A. Once the drill is sharpened, do not remove it from the chuck.

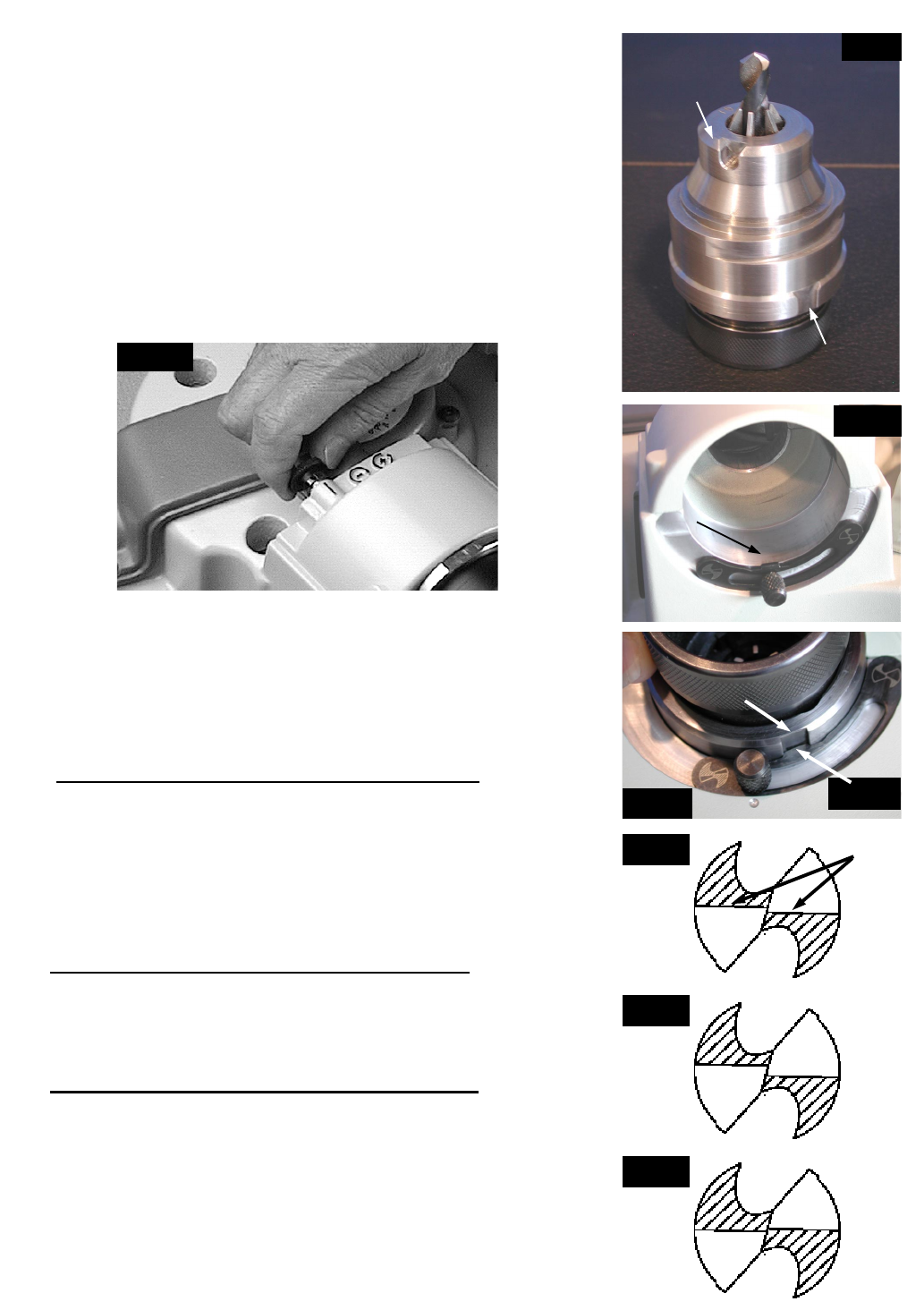

Align the Point Split Tab Notch, on the chuck, with Point Split Tab

on the point split adjustment bracket. Make sure chuck is held in-

line and square with the point split port. (See Picture # 16 & 17a

& 17b)

B. Slide the chuck into the grinding wheel for a “one count” pull

the chuck of the splitting port , about 1/2 inch and rotate it 180

degrees. Repeat “B”.

C. Use the point splitter depth adjustment screw to feed the drill

bit into the wheel. (See Picture #18)

Point Split Depth Adjustment:

What to do if the drill point is split too much or too little:

The point split depth is adjustable. The point split adjustment

screw is located at the rear of the point splitter. (See Picture #18)

If the drill point is changed at the sharpening port then a slight ad-

justment under the following notes will need to be made.

•

Drill point is split correctly: (See Diag ”A”) Use the posi-

tion of the “split line” on the right side of the drill bit as the ref-

erence line. Compare the position of the right “split line” to the

left “split line”. If the “split line” on the right is lower than the

“split line” on the left, the drill bit is under-split or split too lit-

tle. (See Diagram “B”) If the “split line” on the right is higher

than the “split line” on the left, the drill bit is over-split or split

too much. (See Diagram “C”).

•

Drill point is split too little: (See Diag “B”) Turn the ad-

justment screw counterclockwise, (unscrew). Each mark on

the sleeve of the screw will move the drill .002”. Rotate the ad-

justment screw one half of a line, at a time, in the point split

adjustment process. Re-split the point, then check the results.

•

Drill point is split too much: (See Diag “C”) The drill will

need to be realigned and re-sharpened prior to adjusting.

Once the drill is re-sharpened, turn the point split adjustment

knob clockwise approximately one line. Insert the drill into the

point split port and split both sides of the drill. Inspect the drill

point. If the split is now not deep enough then rotate the ad-

justment screw counterclockwise (unscrew), one half of a line.

Re-sharpen, then split the drill point again and check to see if

split is correct, if not, adjust accordingly.

Machine Adjustments

Point Split

Tab Notch

Alignment

Pin Slot

Pic 16

Point Split

Tab

Pic 17a

Pic 18

Diag A

Diag B

Diag C

Split

too

little

Split

too

much

Split

lines

Correct

split

Notch

Tab

Pic 17b