Specifications

Table Of Contents

- Cover

- Table of Contents

- Part 1 List of Functions

- Part 2 Specifications

- Part 3 Printed Circuit Board Connector Wiring Diagram

- Part 4 Function and Control

- Part 5 Operation Manual

- Part 6 Service Diagnosis

- 1. Caution for Diagnosis

- 2. Problem Symptoms and Measures

- 3. Service Check Function

- 4. Code Indication on the Remote Controller

- 5. Troubleshooting

- 5.1 Indoor Units

- 5.2 Outdoor Units

- 5.3 Indoor Unit PCB Abnormality A1

- 5.4 Freeze-up Protection Control or High Pressure Control A5

- 5.5 Fan Motor or Related Abnormality A6

- 5.6 Thermistor or Related Abnormality (Indoor Unit) C4,C9

- 5.7 Front Panel Open / Close Fault C7

- 5.8 Signal Transmission Error (between Indoor and OutdoorUnit) U4

- 5.9 Unspecified Voltage (between Indoor and Outdoor Units) UA

- 5.10 Freeze-up Protection Control A5

- 5.11 Outdoor Unit PCB Abnormality E1

- 5.12 OL Activation (Compressor Overload) E5

- 5.13 Compressor Lock E6

- 5.14 DC Fan Lock E7

- 5.15 Input Over Current Detection E8

- 5.16 Discharge Pipe Temperature Control F3

- 5.17 High Pressure Control in Cooling F6

- 5.18 Compressor Sensor System Abnormality H0

- 5.19 Position Sensor Abnormality H6

- 5.20 CT or Related Abnormality H8

- 5.21 Thermistor or Related Abnormality (Outdoor Unit) P4,J3,J6,J8,J9,H9

- 5.22 Electrical Box Temperature Rise L3

- 5.23 Radiation Fin Temperature Rise L4

- 5.24 Output Over Current Detection L5

- 5.25 Insufficient Gas U0

- 5.26 Low-voltage Detection or Over-voltage Detection U2

- 5.27 Signal Transmission Error (on Outdoor Unit PCB) U7

- 5.28 Anti-icing Function in Other Rooms / UnspecifiedVoltage (between Indoor and Outdoor Units) UA,UH

- 6. Check

- Part 7 Removal Procedure

- Part 8 Others

- Part 9 Appendix

- Index

- Drawings & Flow Charts

Control Specification SiBE12-713

88 Function and Control

3.4 Discharge Pipe Control

Outline The discharge pipe temperature is used as the compressor's internal temperature. If the

discharge pipe temperature rises above a certain level, the operating frequency upper limit is

set to keep this temperature from going up further.

Detail Zones (typical value)

Management within the Zone

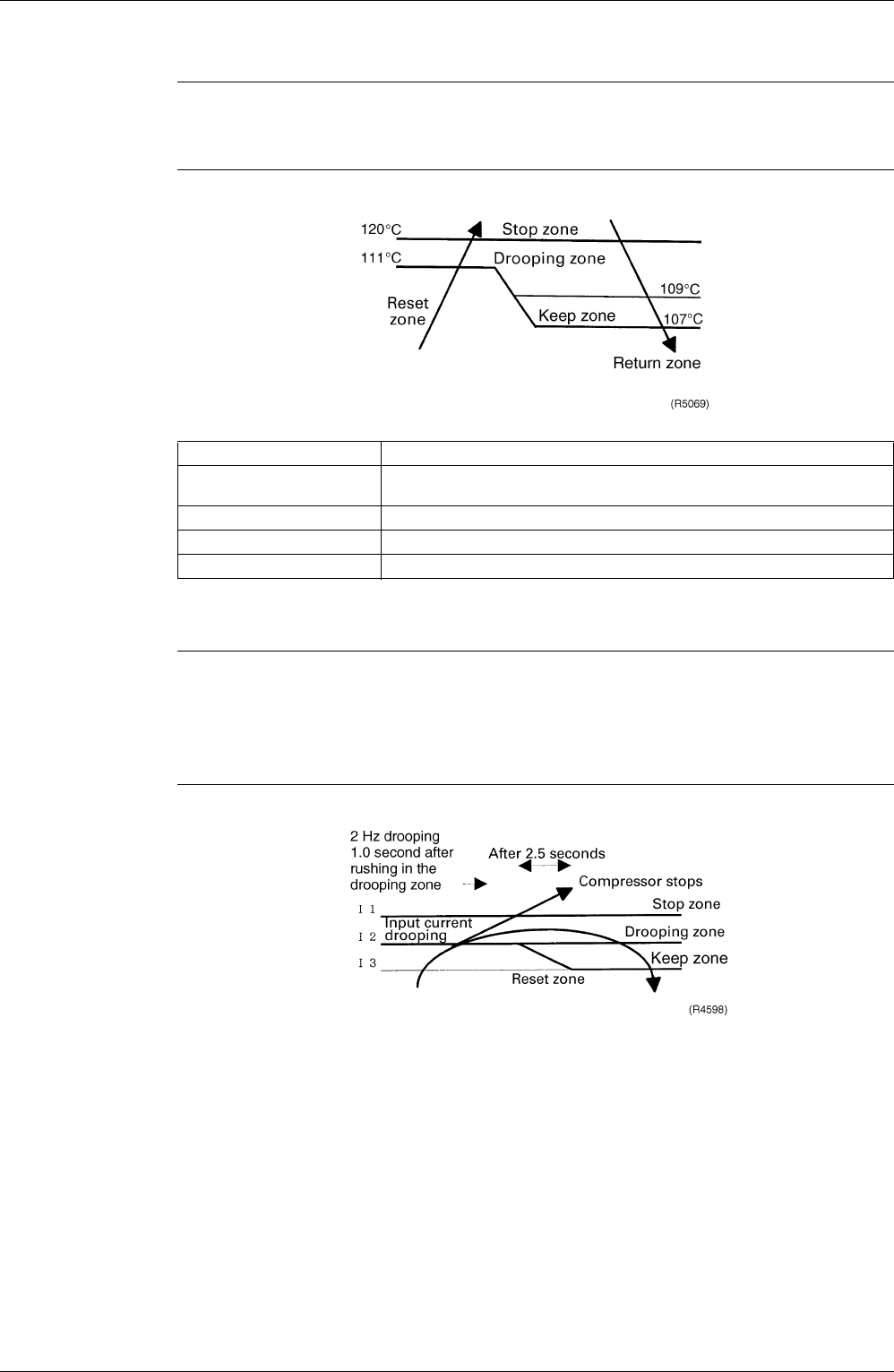

3.5 Input Current Control

Outline Detect an input current by the CT during the compressor is running, and set the frequency

upper limit from such input current.

In case of heat pump model, this control is the upper limit control function of the frequency

which takes priority of the lower limit of four way valve activating compensation.

Detail The frequency control will be made within the following zones.

When a “stop current” continues for 2.5 seconds after rushing on the stop zone, the compressor

operation stops.

If a “drooping current” is continues for 1.0 second after rushing on the drooping zone, the

frequency will be 2 Hz drooping.

Repeating the above drooping continues until the current rushes on the drooping zone without change.

In the unchanged zone, the frequency limit will remain.

In the return / reset zone, the frequency limit will be cancelled.

Limitation of current drooping and stop value according to the outdoor air temperature

1. In case the operation mode is cooling

The current droops when outdoor air temperature becomes higher than a certain level

(model by model).

2. In case the operation mode is heating (only for heat pump model)

The current droops when outdoor air temperature becomes higher than a certain level

(model by model).

Zone Control contents

Stop zone When the temperature reaches the stop zone, stop the compressor and

correct abnormality.

Drooping zone Start the timer, and the frequency will be drooping.

Keep zone Keep the frequency upper limit.

Return / Reset zone Cancel the frequency upper limit.