Specifications

Table Of Contents

- Cover

- Table of Contents

- Part 1 List of Functions

- Part 2 Specifications

- Part 3 Printed Circuit Board Connector Wiring Diagram

- Part 4 Function and Control

- Part 5 Operation Manual

- Part 6 Service Diagnosis

- 1. Caution for Diagnosis

- 2. Problem Symptoms and Measures

- 3. Service Check Function

- 4. Code Indication on the Remote Controller

- 5. Troubleshooting

- 5.1 Indoor Units

- 5.2 Outdoor Units

- 5.3 Indoor Unit PCB Abnormality A1

- 5.4 Freeze-up Protection Control or High Pressure Control A5

- 5.5 Fan Motor or Related Abnormality A6

- 5.6 Thermistor or Related Abnormality (Indoor Unit) C4,C9

- 5.7 Front Panel Open / Close Fault C7

- 5.8 Signal Transmission Error (between Indoor and OutdoorUnit) U4

- 5.9 Unspecified Voltage (between Indoor and Outdoor Units) UA

- 5.10 Freeze-up Protection Control A5

- 5.11 Outdoor Unit PCB Abnormality E1

- 5.12 OL Activation (Compressor Overload) E5

- 5.13 Compressor Lock E6

- 5.14 DC Fan Lock E7

- 5.15 Input Over Current Detection E8

- 5.16 Discharge Pipe Temperature Control F3

- 5.17 High Pressure Control in Cooling F6

- 5.18 Compressor Sensor System Abnormality H0

- 5.19 Position Sensor Abnormality H6

- 5.20 CT or Related Abnormality H8

- 5.21 Thermistor or Related Abnormality (Outdoor Unit) P4,J3,J6,J8,J9,H9

- 5.22 Electrical Box Temperature Rise L3

- 5.23 Radiation Fin Temperature Rise L4

- 5.24 Output Over Current Detection L5

- 5.25 Insufficient Gas U0

- 5.26 Low-voltage Detection or Over-voltage Detection U2

- 5.27 Signal Transmission Error (on Outdoor Unit PCB) U7

- 5.28 Anti-icing Function in Other Rooms / UnspecifiedVoltage (between Indoor and Outdoor Units) UA,UH

- 6. Check

- Part 7 Removal Procedure

- Part 8 Others

- Part 9 Appendix

- Index

- Drawings & Flow Charts

Outdoor Unit SiBE12-713

316 Removal Procedure

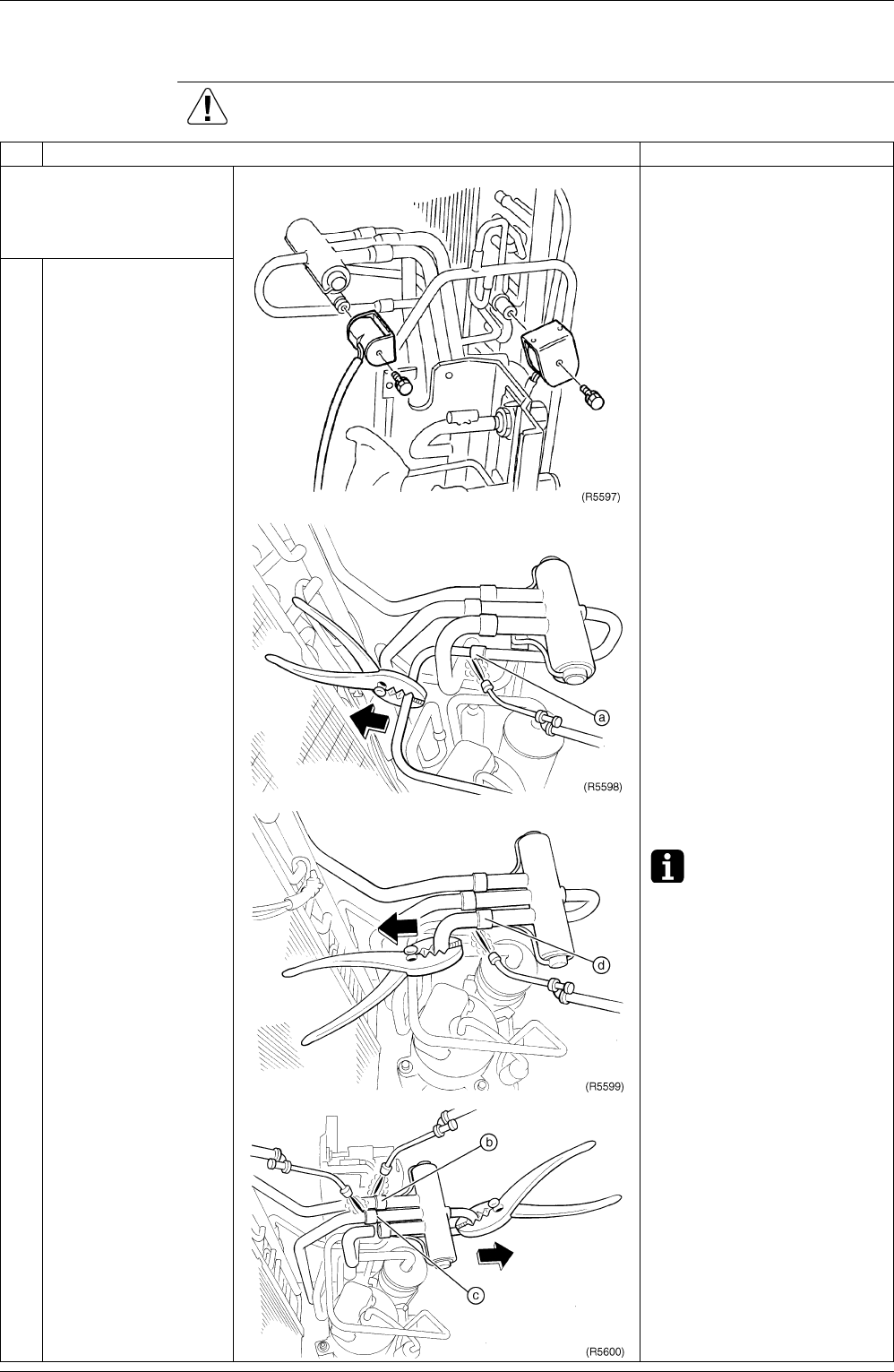

1.8 Removal of the Four Way Valve

Procedure Warning Be sure to wait 10 minutes or more after turning off all power supplies

before disassembling work.

Step

Procedure Points

Be sure to apply nitrogen

replacement when

heating up the brazed

part.

Cautions for restoration

1. Restore the piping by non-

oxidation brazing.

In case of you cannot use

the nitrogen gas, restore as

quickly as possible.

2. It is required to prevent the

carbonization of the oil inside

the four way valve and the

deterioration of the gaskets

affected by heat. For the

sake of this, wrap the four

way valve with wet cloth and

provide water so that the

cloth will not be dried and

avoid excessive heating.

(Keep below 120°C)

Be careful so as not to break

the pipes by pressing it

excessively by pliers when

withdrawing it.

In case of the difficulty with

gas brazing machine

1. Disconnect the brazed part

where is easy to disconnect

and restore.

2. Cut pipes on the main unit by

a miniature copper tube

cutter in order to make it

easy to disconnect.

Note: Do not use a metal

saw for cutting pipes by all

means because the sawdust

come into the circuit.

1

Loosen the 1 screw to

remove the four way

valve coil.

2

Heat up the 4 brazed

part of the four way

valve. First, disconnect

the part "a".

Provide a protective

sheet or a steel

plate so that the

brazing flame

cannot influence

peripheries.

3

Disconnect the part "d".

4

Disconnect the part "b"

and "c".