Specifications

Table Of Contents

- Cover

- Table of Contents

- Part 1 List of Functions

- Part 2 Specifications

- Part 3 Printed Circuit Board Connector Wiring Diagram

- Part 4 Function and Control

- Part 5 Operation Manual

- Part 6 Service Diagnosis

- 1. Caution for Diagnosis

- 2. Problem Symptoms and Measures

- 3. Service Check Function

- 4. Code Indication on the Remote Controller

- 5. Troubleshooting

- 5.1 Indoor Units

- 5.2 Outdoor Units

- 5.3 Indoor Unit PCB Abnormality A1

- 5.4 Freeze-up Protection Control or High Pressure Control A5

- 5.5 Fan Motor or Related Abnormality A6

- 5.6 Thermistor or Related Abnormality (Indoor Unit) C4,C9

- 5.7 Front Panel Open / Close Fault C7

- 5.8 Signal Transmission Error (between Indoor and OutdoorUnit) U4

- 5.9 Unspecified Voltage (between Indoor and Outdoor Units) UA

- 5.10 Freeze-up Protection Control A5

- 5.11 Outdoor Unit PCB Abnormality E1

- 5.12 OL Activation (Compressor Overload) E5

- 5.13 Compressor Lock E6

- 5.14 DC Fan Lock E7

- 5.15 Input Over Current Detection E8

- 5.16 Discharge Pipe Temperature Control F3

- 5.17 High Pressure Control in Cooling F6

- 5.18 Compressor Sensor System Abnormality H0

- 5.19 Position Sensor Abnormality H6

- 5.20 CT or Related Abnormality H8

- 5.21 Thermistor or Related Abnormality (Outdoor Unit) P4,J3,J6,J8,J9,H9

- 5.22 Electrical Box Temperature Rise L3

- 5.23 Radiation Fin Temperature Rise L4

- 5.24 Output Over Current Detection L5

- 5.25 Insufficient Gas U0

- 5.26 Low-voltage Detection or Over-voltage Detection U2

- 5.27 Signal Transmission Error (on Outdoor Unit PCB) U7

- 5.28 Anti-icing Function in Other Rooms / UnspecifiedVoltage (between Indoor and Outdoor Units) UA,UH

- 6. Check

- Part 7 Removal Procedure

- Part 8 Others

- Part 9 Appendix

- Index

- Drawings & Flow Charts

Specifications SiBE12-713

18 Specifications

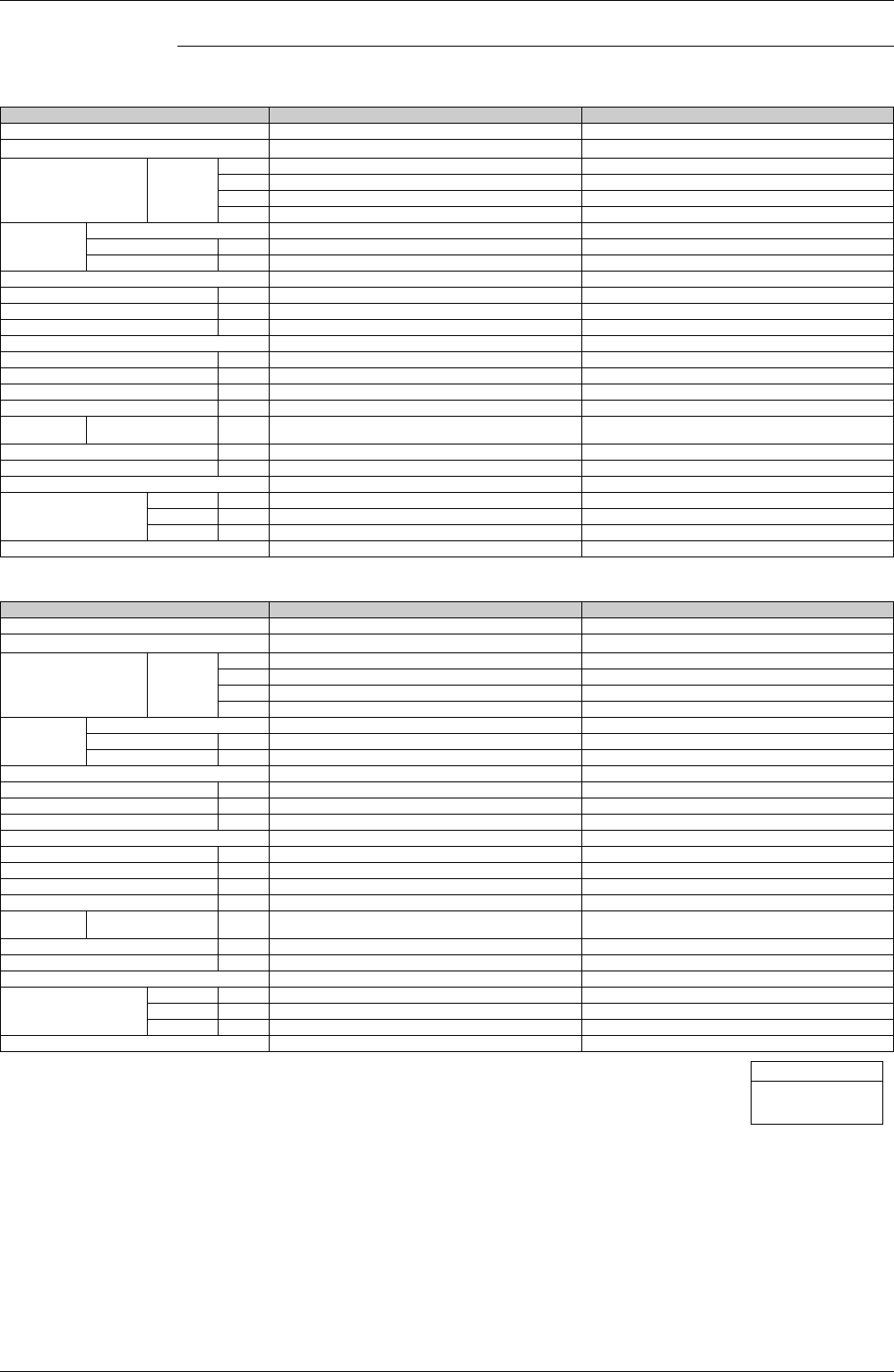

Duct Connected Type

50Hz 230V

Note:

1. The operating sound is based on the rear side suction inlet and the external static pressure 40 Pa.

Operating sound for under side suction inlet: [operating sound for rear side suction inlet]+5 dB.

However, when installation to which the external static pressure becomes low is carried out,

5 dB or more may go up.

Model FDKS25CAVMB FDKS35CAVMB

Rated Capacity 2.5kW Class 3.5kW Class

Front Panel Color

——

Air Flow Rates

m³/min

(cfm)

H 9.5 (335) 10.0 (353)

M 8.8 (311) 9.3 (328)

L 8.0 (282) 8.5 (300)

SL 6.7 (237) 7.0 (247)

Fan

Type Sirocco Fan Sirocco Fan

Motor Output W 62 62

Speed Steps 5 Steps, Quiet, Auto 5 Steps, Quiet, Auto

Air Filter Removable-Washable-Mildew Proof Removable-Washable-Mildew Proof

Running Current (Rated) A 0.47 0.47

Power Consumption (Rated) W 100 100

Power Factor % 92.5 92.5

Temperature Control Microcomputer Control Microcomputer Control

Dimensions (H×W×D) mm 200×900×620 200×900×620

Packaged Dimensions (H×W×D) mm 266×1,106×751 266×1,106×751

Weight kg 25 25

Gross Weight kg 31 31

Operation

Sound

H/M/L/SL dBA 35/33/31/29 35/33/31/29

External Static Pressure Pa 40 40

Moisture Removal L/h 1.2 1.9

Heat Insulation Both Liquid and Gas Pipes Both Liquid and Gas Pipes

Piping Connection

Liquid mm

φ

6.4

φ

6.4

Gas mm

φ

9.5

φ

9.5

Drain mm VP20 (O.D.

φ

26 / I.D.

φ

20) VP20 (O.D.

φ

26 / I.D.

φ

20)

Drawing No. 3D048947C 3D048948C

Conversion Formulae

kcal/h=kW×860

Btu/h=kW×3414

cfm=m³/min×35.3

Model FDKS50CVMB FDKS60CVMB

Rated Capacity 5.0kW Class 6.0kW Class

Front Panel Color

——

Air Flow Rates

m³/min

(cfm)

H 12.0 (424) 16.0 (565)

M 11.0 (388) 14.8 (523)

L 10.0 (353) 13.5 (477)

SL 8.4 (297) 11.2 (395)

Fan

Type Sirocco Fan Sirocco Fan

Motor Output W 130 130

Speed Steps 5 Steps, Quiet, Auto 5 Steps, Quiet, Auto

Air Filter Removable-Washable-Mildew Proof Removable-Washable-Mildew Proof

Running Current (Rated) A 0.64 0.74

Power Consumption (Rated) W 140 160

Power Factor % 95.1 94.0

Temperature Control Microcomputer Control Microcomputer Control

Dimensions (H×W×D) mm 200×900×620 200×1,100×620

Packaged Dimensions (H×W×D) mm 266×1,106×751 266×1,306×751

Weight kg 27 30

Gross Weight kg 34 37

Operation

Sound

H/M/L/SL dBA 37/35/33/31 38/36/34/32

External Static Pressure Pa 40 40

Moisture Removal L/h 2.9 3.9

Heat Insulation Both Liquid and Gas Pipes Both Liquid and Gas Pipes

Piping Connection

Liquid mm

φ

6.4

φ

6.4

Gas mm

φ

12.7

φ

12.7

Drain mm VP20 (O.D.

φ

26 / I.D.

φ

20) VP20 (O.D.

φ

26 / I.D.

φ

20)

Drawing No. 3D052134A 3D052135