Specifications

Table Of Contents

- Cover

- Table of Contents

- Part 1 List of Functions

- Part 2 Specifications

- Part 3 Printed Circuit Board Connector Wiring Diagram

- Part 4 Function and Control

- Part 5 Operation Manual

- Part 6 Service Diagnosis

- 1. Caution for Diagnosis

- 2. Problem Symptoms and Measures

- 3. Service Check Function

- 4. Code Indication on the Remote Controller

- 5. Troubleshooting

- 5.1 Indoor Units

- 5.2 Outdoor Units

- 5.3 Indoor Unit PCB Abnormality A1

- 5.4 Freeze-up Protection Control or High Pressure Control A5

- 5.5 Fan Motor or Related Abnormality A6

- 5.6 Thermistor or Related Abnormality (Indoor Unit) C4,C9

- 5.7 Front Panel Open / Close Fault C7

- 5.8 Signal Transmission Error (between Indoor and OutdoorUnit) U4

- 5.9 Unspecified Voltage (between Indoor and Outdoor Units) UA

- 5.10 Freeze-up Protection Control A5

- 5.11 Outdoor Unit PCB Abnormality E1

- 5.12 OL Activation (Compressor Overload) E5

- 5.13 Compressor Lock E6

- 5.14 DC Fan Lock E7

- 5.15 Input Over Current Detection E8

- 5.16 Discharge Pipe Temperature Control F3

- 5.17 High Pressure Control in Cooling F6

- 5.18 Compressor Sensor System Abnormality H0

- 5.19 Position Sensor Abnormality H6

- 5.20 CT or Related Abnormality H8

- 5.21 Thermistor or Related Abnormality (Outdoor Unit) P4,J3,J6,J8,J9,H9

- 5.22 Electrical Box Temperature Rise L3

- 5.23 Radiation Fin Temperature Rise L4

- 5.24 Output Over Current Detection L5

- 5.25 Insufficient Gas U0

- 5.26 Low-voltage Detection or Over-voltage Detection U2

- 5.27 Signal Transmission Error (on Outdoor Unit PCB) U7

- 5.28 Anti-icing Function in Other Rooms / UnspecifiedVoltage (between Indoor and Outdoor Units) UA,UH

- 6. Check

- Part 7 Removal Procedure

- Part 8 Others

- Part 9 Appendix

- Index

- Drawings & Flow Charts

Troubleshooting SiBE12-713

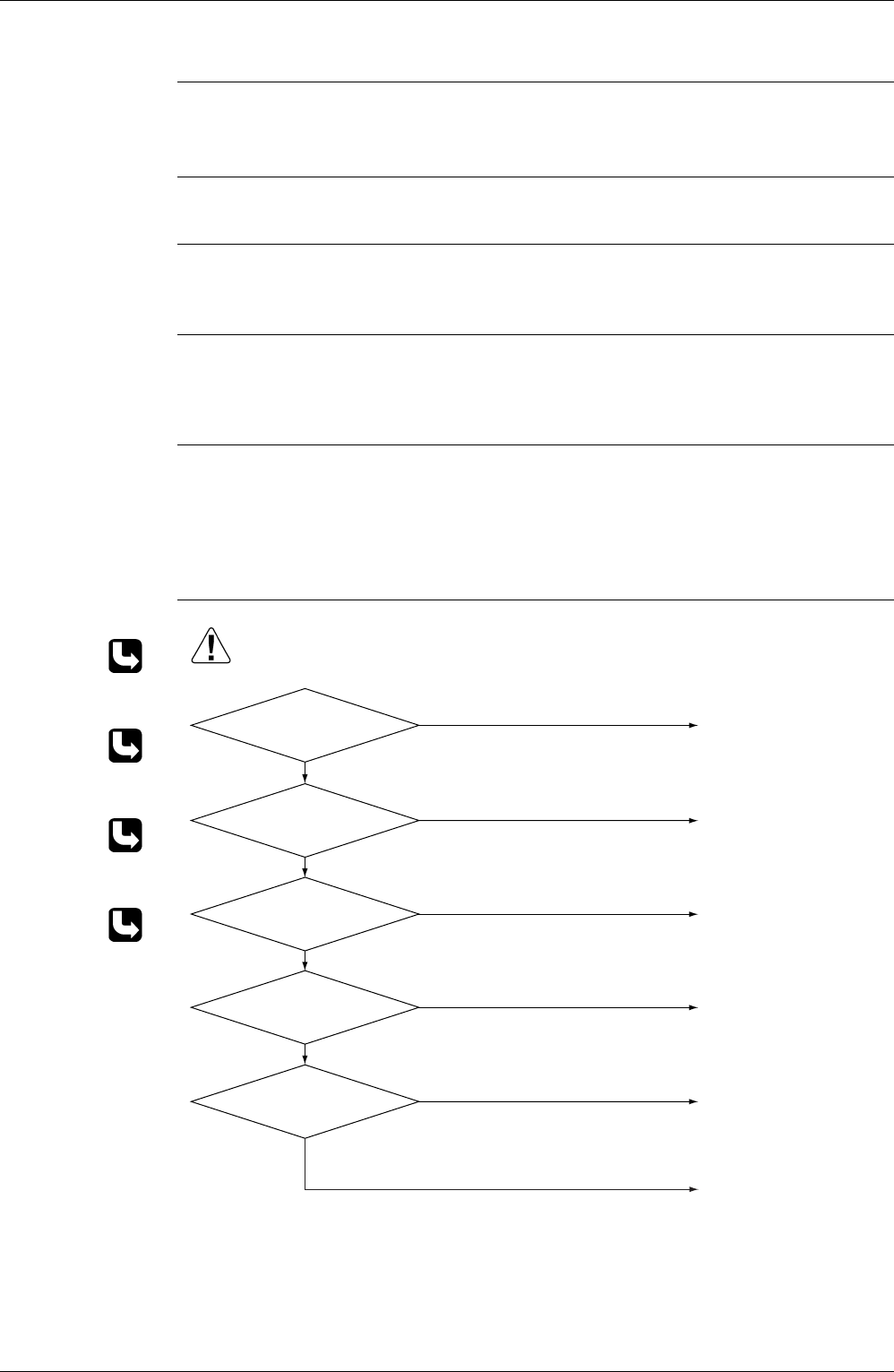

250 Service Diagnosis

5.12 OL Activation (Compressor Overload)

Remote

Controller

Display

E5

Outdoor Unit LED

Display

A

5

1

4

2

1

3

4

4

1

Method of

Malfunction

Detection

A compressor overload is detected through compressor OL.

Malfunction

Decision

Conditions

If the compressor OL is activated twice, the system will be shut down.

The error counter will reset itself if this or any other error does not occur during the following

60-minute compressor running time (total time).

∗

The operating temperature condition is not specified.

Supposed

Causes

Refrigerant shortage

Four way valve malfunctioning

Outdoor unit PCB defective

Water mixed in the local piping

Electronic expansion valve defective

Stop valve defective

Troubleshooting

Check No.04

Refer to P.277

Check No.05

Refer to P.278

Check No.06

Refer to P.279

Check No.11

Refer to P.282

Insert the thermistor in

position.

Replace the discharge pipe

thermistor.

Replace the valve itself or

the coil.

Replace the four way valve

coil or the valve itself.

Replace the outdoor unit

PCB.

Refer to the refrigerant line

check procedure.

(R4697)

Caution

Be sure to turn off power switch before connect or disconnect connector,

or parts damage may be occurred.

Discharge pipe thermistor

disconnected?

YES

Malfunctioning

∗ Discharge pipe thermistor

NO

Functioning

Functioning

Check No. 11

Check the refrigerant line.

Malfunctioning

∗ Refrigerant shortage

∗ Water mixed

∗ Stop valve defective

Check No. 06

Check the thermistors

Malfunctioning

Functioning

Check No. 04

Check the electronic expantion

valve.

Malfunctioning

Functioning

Check No. 05

Check the four way valve.

Replace the outdoor unit

PCB.