Operator`s manual

Section5: Maintenance

_ eforeinspecting,cleaningorservicing themachine,shutoffengine,waitformovingpartstostop,dis- I

connectsparkplugwire andmovewire awayfromsparkplug.

Failureto followtheseinstructionscanresultin seriouspersonalnjuryor propertydamage.

Figure5-17: Dislodginghandlebarstruts.

2. Foldthe top section of the assembly

backward(2, Figure5-16). Guidethe

cablescarefullywhile folding. Besure

not to bend,pinch, or stretchthe cables.

IMPORTANT:To avoid damageto cables,

alwaysfold the top sectionof the

handlebarassemblybackwardandthe

bottom sectionforward.

3. Still supportingthehandlebar

assemblywith onehand,loosenthe two

lower handlebaradjustmentknobs

(3, Figure5-16) just enoughto dislodge

both handlebarstruts (L, Figure5-17)

from the slots (K) inthe wheel bracket

assembly.

NOTE:Thehandlebarheightcould inad-

vertentlychangeif the lower adjustment

knobsareloosenedexcessivelyduring

this step.

4. Carefullyfold the bottom sectionof

the handlebarassemblyforward overthe

engine(4, Figure5-16). Guidethe cables

carefullywhilefolding. Besure not to

bend,pinch, or stretchthe cables;also,

keepcablesawayfrom muffler -- the

outer cablecoveringcanbe burnedifthe

engineis still hot.

5. To unfold handlebarassembly,

performfolding stepsin reverseorder.

PINIONGEARSERVICE

Themowerdrive wheels(rearwheels)

eachcontaina pinion gear. Thisgear

transfersdrive powerto the wheelswhich

propelsthe mowerforward. It is very

importantto keeptheseinternalparts

clean. Thefollowing procedureexplains

how to disassemble,cleanand reassem-

blethemowerdrive wheels. Conductthis

maintenanceonthe pinion gearsafter

every50 operatinghours.

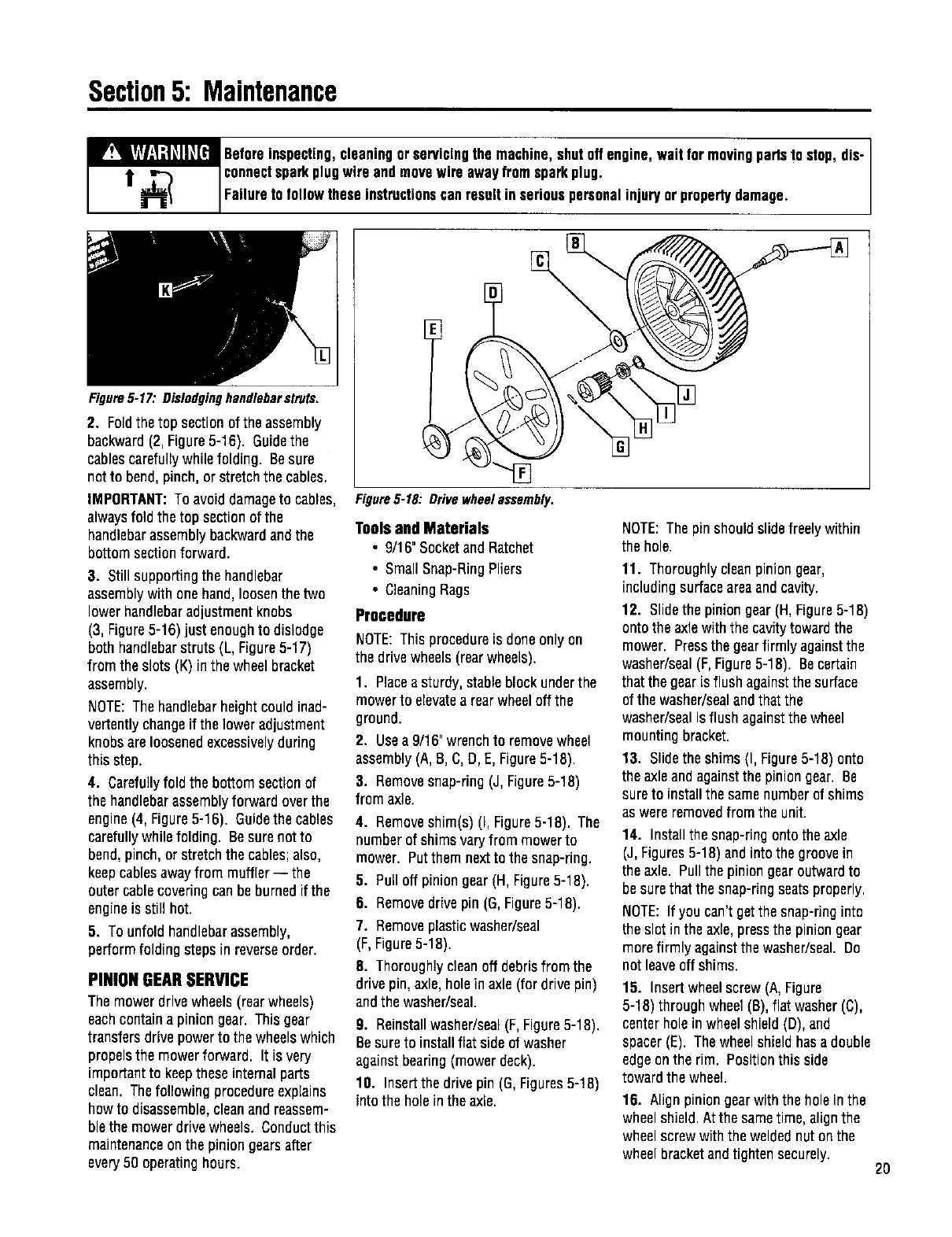

Figure5-18: Drivewheelassembly.

Toolsand Materials

• 9/16" SocketandRatchet

• Small Snap-RingPliers

• CleaningRags

Procedure

NOTE:Thisprocedureis doneonly on

the drivewheels(rearwheels).

1. Placeasturdy, stableblockunderthe

mowerto elevatea rearwheeloff the

ground.

2. Usea 9/16"wrenchto removewheel

assembly(A, 8, C,D,E, Figure5-18).

3. Removesnap-ring (J, Figure5-18)

from axle.

4. Removeshim(s) (I, Figure5-18). The

numberof shims varyfrom mowerto

mower. Putthem nextto thesnap-ring.

5. Pulloff piniongear(H, Figure5-18).

6. Removedrive pin (G,Figure5-18).

7. Removeplasticwasher/seal

(F,Figure5-18).

8. Thoroughlycleanoff debrisfrom the

drive pin, axle,holein axle(for drive pin)

andthe washer/seal.

9. Reinstallwasher/seal(F,Figure5-18).

Besure to installflat side of washer

againstbearing(mowerdeck).

10. Insertthe drive pin (G,Figures5-18)

intothe holein the axle.

NOTE:Thepin should slidefreelywithin

the hole.

11. Thoroughlycleanpinion gear,

including surfaceareaand cavity.

12. Slidethe pinion gear(H,Figure5-18)

onto the axlewith the cavitytowardthe

mower. Pressthe gearfirmly againstthe

washer/seal(F,Figure5-18). Becertain

that the gearLsflush againstthe surface

of the washer/sealandthat the

washer/sealisflush againstthe wheel

mountingbracket.

13. Slidethe shims (I, Figure5-18) onto

the axleandagainstthe piniongear. Be

sureto installthe samenumber of shims

as wereremovedfrom the unit.

14. Installthe snap-ringonto the axle

(J,Figures5-18) andinto the groovein

the axle. Pullthe piniongearoutwardto

besurethatthe snap-ringseatsproperly.

NOTE: If you can't getthe snap-ringinto

the slot in the axle,pressthepinion gear

morefirmly againstthe washer/seal. Do

not leaveoff shims.

15. Insert wheelscrew (A,Figure

5-18) through wheel(B),flat washer(C),

centerholein wheelshield (D), and

spacer(E). Thewheelshieldhas adouble

edgeonthe rim. Positionthis side

towardthewheel.

16. Align piniongearwith the holeinthe

wheelshield.At the sametime, alignthe

wheelscrew with the weldednut on the

wheel bracketandtightensecurely.

2O