User Manual

Table Of Contents

- SECTION 1: important safe operation practices

- SECTION 2: slope gauge

- SECTION 3: tractor set-up

- Gas and Oil Fill-up

- Setting the Gauge Wheels and Roller

- SECTION 4: know your lawn tractor

- Throttle Control Lever

- Choke Control

- Brake Pedal

- Seat Adjustment Lever

- Ignition Switch Module

- Drive Pedal

- Systems Indicator Monitor / Hour Meter

- Deck Lift Lever

- Electric PTO / Blade Engage Knob

- Cruise Control Lever

- Parking Brake Lever

- SECTION 5: operating your lawn tractor

- Safety Interlock Switches

- Reverse Caution Mode

- Starting the Engine

- Stopping the Engine

- Engaging the Parking Brake

- Driving The Tractor

- Driving On Slopes

- Setting The Cruise Control

- Using the Deck Lift Lever

- Operating the Headlights

- Moving The Tractor Manually

- Engaging the PTO

- Mowing

- SECTION 6: making adjustments

- Leveling the Deck

- Parking Brake Adjustment

- Seat Adjustment

- Steering Adjustment

- SECTION 7: maintaining your lawn tractor

- Engine

- Changing the Engine OIl

- Air Filter

- Cleaning the Engine And Deck

- Lubrication

- Carburetor

- SECTION 8: service

- Tires

- Fuse

- Cutting Blades

- Battery

- Cutting Deck Removal

- Changing the Deck Belt

- Changing The Transmission Drive Belt

- Hydrostatic Transmission

- SECTION 9: off-season storage

- Engine

- SECTION 10: maintenance chart

- SECTION 11: maintenance log

- SECTION 12: troubleshooting

- SECTION 13: attachments & accessories

- SECTION 14: Replacement Parts

- SECTION 15: specifications*

18

SECTION 7: MAINTAINING YOUR LAWN TRACTOR

NOTE: Refer to Maintenance Chart on page 28 for a

reference of recommended maintenance intervals.

WARNING: Before performing any

maintenance or repairs, disengage PTO, set

parking brake, stop engine and remove key to

prevent unintended starting.

Engine

Maintenance, repair, or replacement of the emission

control devices and systems, which are being done at

the customer’s expense, may be performed by any

engine repair establishment or individual. Warranty

repairs must be performed by a Cub Cadet Dealer.

Engine Oil Recommendations

Using the proper type and weight of engine oil is

extremely important. So is checking and changing oil

regularly. Failure to use the correct oil, or operating the

engine with dirty oil will result in premature engine wear

and failure.

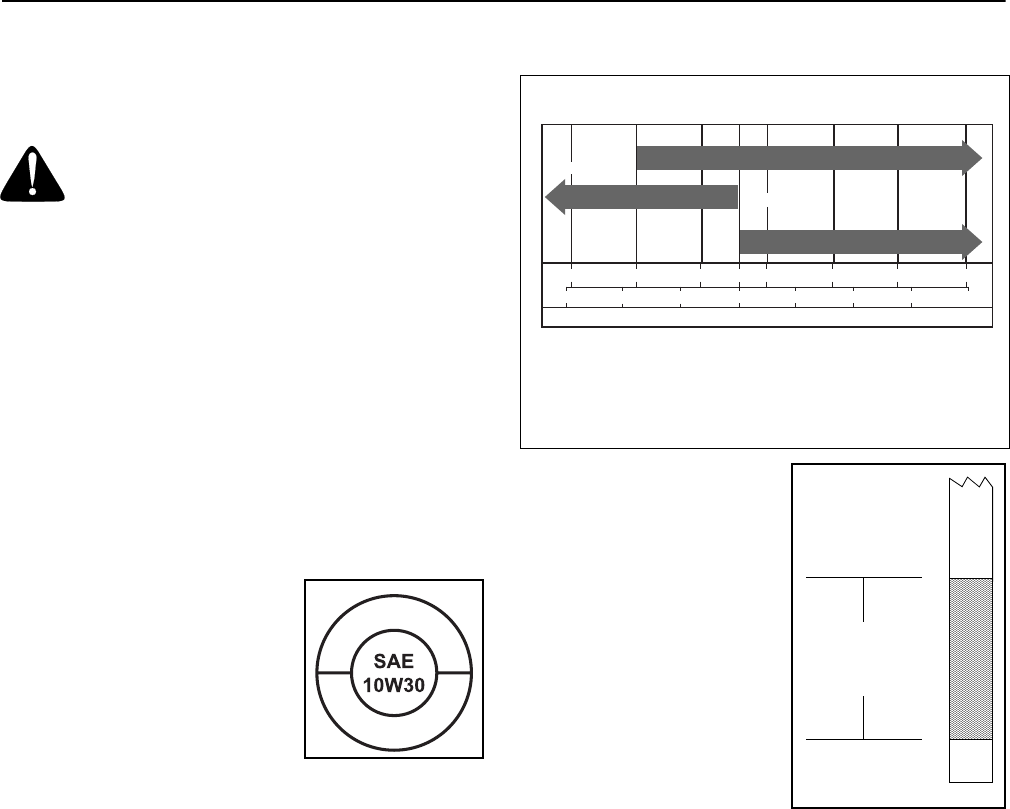

Engine Oil Type

Use only a high quality detergent

oil of API (American Petroleum

Institute) service class SG, SH,

SJ or higher. Selection of engine

oil should be based on the lowest

anticipated temperatures prior to

the next scheduled oil change.

Refer to the Temperature / Oil Viscosity Chart.

Checking the Oil Level

It is important to check the oil level at least every four

hours of operation. Regular checking during the first 24

hours of operation is especially important. Check the oil

level before each use as follows:

• Allow the engine a few minutes to rest after opera-

tion. This will give the oil time to drain into the crank-

case sump and result in a more accurate dipstick

reading.

• Clean the area around the oil fill cap/dipstick to pre-

vent debris from entering the crankcase.

• Remove the oil fill cap/dipstick by lifting it (single

cylinder models) or twisting it (twin cylinder models)

out of the oil fill tube.

• Wipe the dipstick clean before pushing it all the way

back into the oil fill tube. Withdraw the dipstick to

check the oil level. Refer to figure at right.

• Always keep the oil level at or near the FULL mark

on the dipstick. If the oil is low, add oil of the proper

type up to the FULL mark. Always re-check the oil

level with the dipstick before adding more oil.

IMPORTANT:

Never operate

the engine with the oil level

outside of the Operating

Range on the dipstick.

• After checking the oil

level (and adding oil, if

necessary), reinstall the

oil fill cap/dipstick onto

the oil fill tube.

Adding Oil

If, after checking the oil level,

you find the dipstick reads L,

proceed as follows.

• Place the tractor on a level surface. Engage the

parking brake, stop the engine and remove the key.

• Clean the area around the oil fill cap and fill tube to

prevent debris from entering the crankcase.

• Remove the oil fill cap/dipstick from the oil fill tube

and SLOWLY pour oil into the oil fill tube. Do NOT

pour more than 6 oz. of oil at a time without first

stopping and re-checking the oil level.

• Fill the crankcase until the oil level reaches the full

(F) mark on the dipstick. See Figure above. Refer to

the viscosity oil chart for information regarding the

proper type of oil to add to the crankcase.

IMPORTANT:

The engine may overheat and/or damage

may result if the oil level is below the L or above the F

on the dipstick.

• Reinstall the oil fill cap/dipstick securely onto the oil

fill tube.

IMPORTANT:

The oil fill cap/dipstick must be installed

securely onto the tube at all times when the engine

is operating. Severe engine damage could result from

failure to do so.

A

P

I

S

E

R

V

I

C

E

S

J

F

L

Operating Range

TEMPERATURE / OIL VISCOSITY CHART

Temperature Change Expected Before Next Oil Change

°C

°F

403020100-10-20-30

10080604032200-20

5W-20, 5W-30

10W-30 (Twin Cylinder)

10W-30 (Single Cylinder)

*Use of synthetic oil having 5W-20 or 5W-30 rating is acceptable,

up to 4°C (40°F).

**Synthetic oils will provide better starting in extreme cold below

23°C (-10°F).

**

*