Manual

Table Of Contents

- THE ROUTER TABLE

- ASSEMBLY INSTRUCTIONS

- Assembly of legs

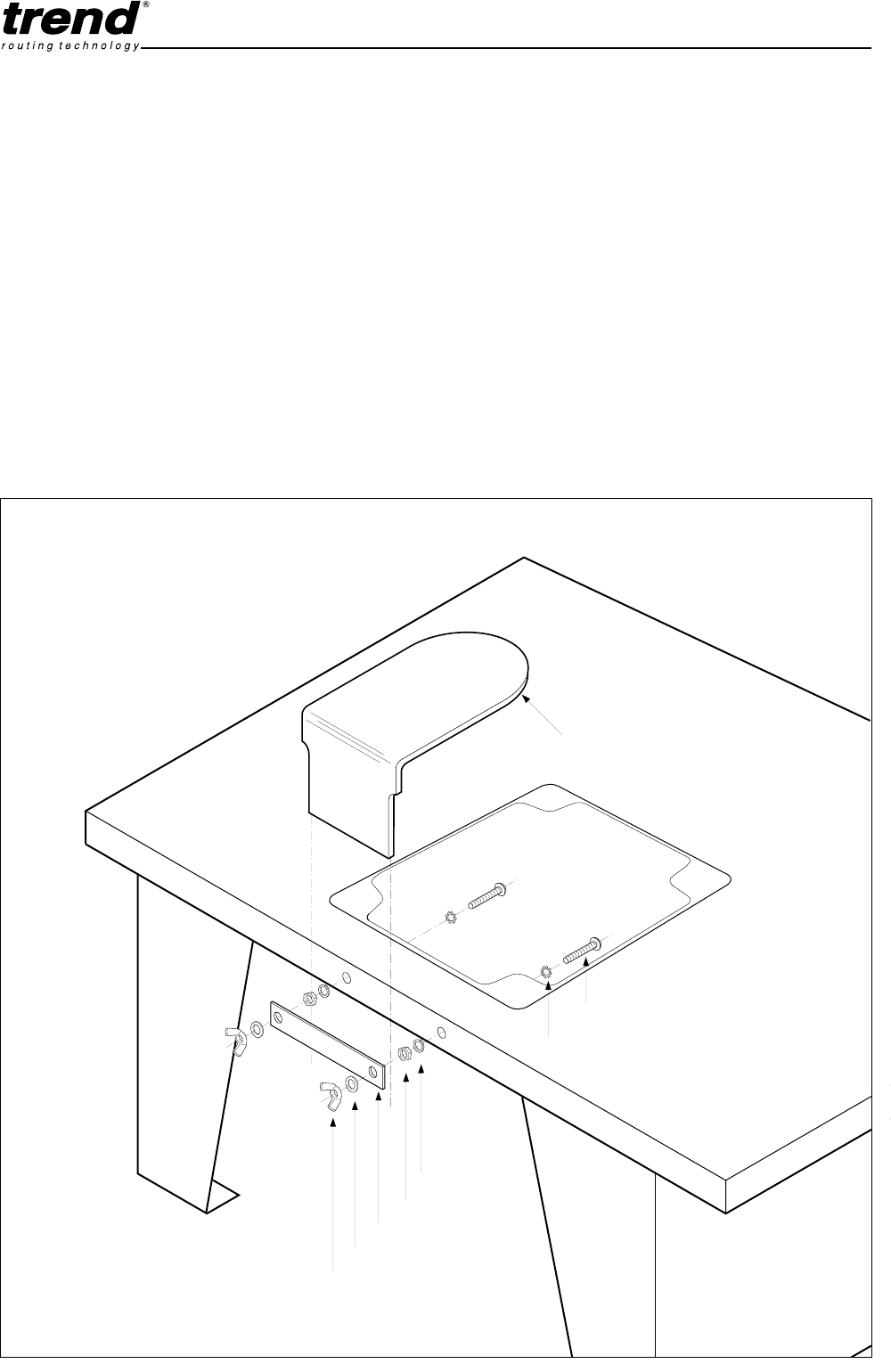

- Mounting Table to Workbench or Workboard

- Mounting Table to a Workmate

- Identification of Mounting Holes and Screws

- Re-Drilling of Router Base

- Re-Drilling of Insert Plate

- Re-Drilling of Insert Plate and Router base

- Fitting Insert Plate to Table Surface

- Fitting Router to Insert Plate

- Selecting & Fitting Insert Plate Rings

- Fitting Lead-on Pin

- Assembly & Mounting of Tenon Push Block

- Assembly of Safety Dust Guard to Back Fence

- Assembly of Back Fence

- Attachment of Back Fence to Table

- Assembly & Alignment of Mitre Fence

- Fitting of No-Volt Release Switch

- OPTIONAL ACCESSORIES

- OPERATION

- APPENDIX

-20-

Router Table for the Craftsman

U.

Assembly of Profiling Top Guard

The use of the optional accessory, Profiling Top Guard

is highly recommended to safely carry out the profiling of

workpieces with a bearing guided cutter. It will prevent

the operator's fingers inadvertantly contacting the cutter.

1.

Fit the Bolt, Star Washer, Spring Washer and Nut

in the sequence as indicated below.

2.

Tighten nut securely with a 8mm spanner.

3.

Fit Plate, Washer and Wing Nut.

4.

Slide the Perspex Guard in between the Plate and

edge of Table Surface.

5.

Gently tighten Wing Nuts.

Adjustment

1.

The height of the Perspex Guard should be

adjusted to leave a 6mm to 12mm gap between the

top of the workpiece and the underside of the

guard. This will prevent fingers coming into contact

with the cutter.

2.

To adjust the height undo the wing nuts, re-position

the guard and retighten.

Section Y describes a typical application involving the

use of bearing guided cutters with the Router Table.

fig. T

Wing Nut

Washer

Plate

Half Nut

Spring Washer

Star Washer

Perspex Guard

M5 Bolt

Profiling Top Guard - CRT/2