Manual

Table Of Contents

- THE ROUTER TABLE

- ASSEMBLY INSTRUCTIONS

- Assembly of legs

- Mounting Table to Workbench or Workboard

- Mounting Table to a Workmate

- Identification of Mounting Holes and Screws

- Re-Drilling of Router Base

- Re-Drilling of Insert Plate

- Re-Drilling of Insert Plate and Router base

- Fitting Insert Plate to Table Surface

- Fitting Router to Insert Plate

- Selecting & Fitting Insert Plate Rings

- Fitting Lead-on Pin

- Assembly & Mounting of Tenon Push Block

- Assembly of Safety Dust Guard to Back Fence

- Assembly of Back Fence

- Attachment of Back Fence to Table

- Assembly & Alignment of Mitre Fence

- Fitting of No-Volt Release Switch

- OPTIONAL ACCESSORIES

- OPERATION

- APPENDIX

Router Table for the Craftsman

-19-

T.

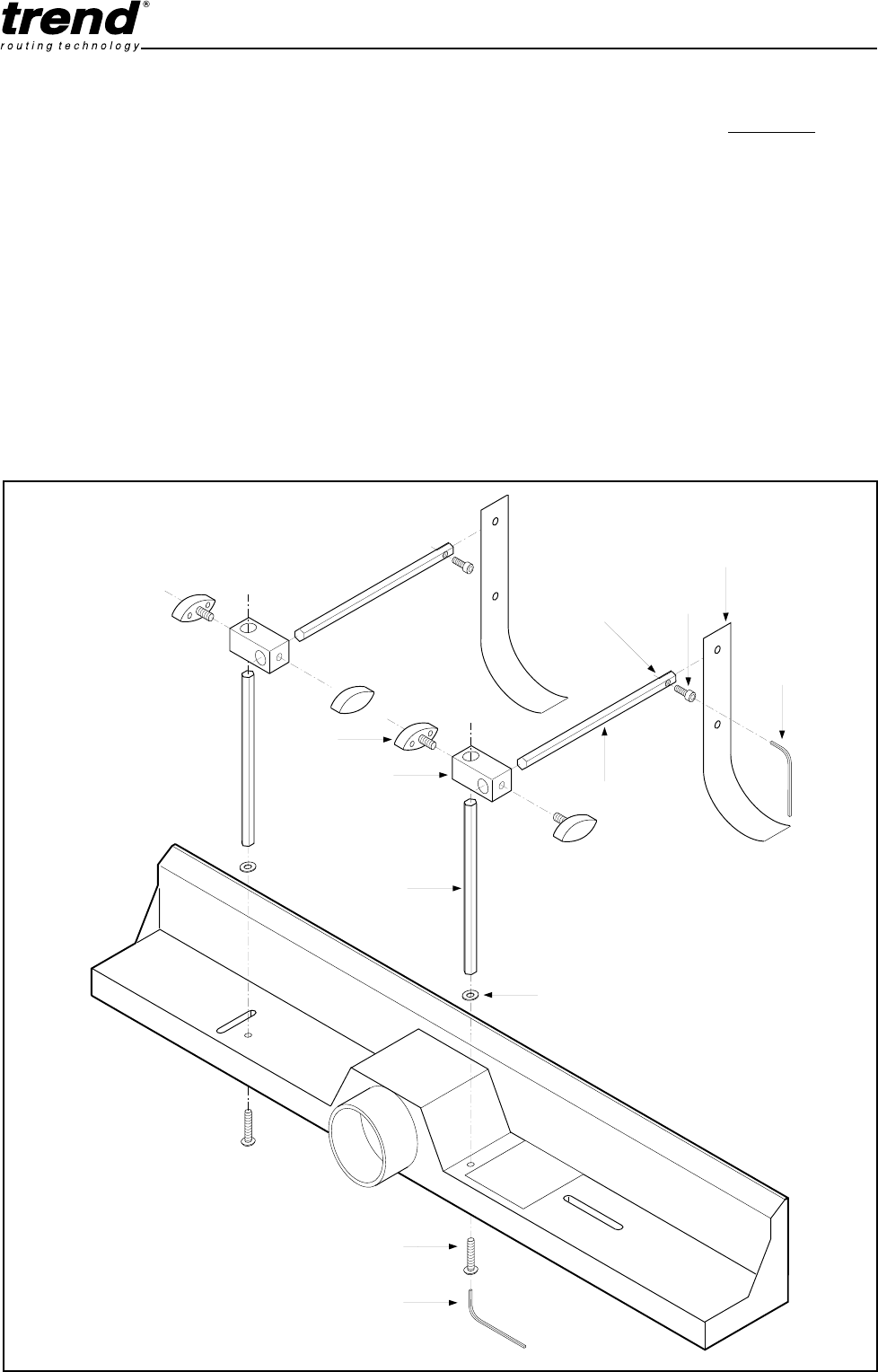

Assembly of Spring Pressure Clamps

The Optional Spring Pressure Clamps can be mounted

to the Back Fence. When adjusted to suit the width and

thickness of the material, it ensures the material is held

down onto the surface to obtain accurate machining of

the workpiece.

The Back Fence is pre-drilled to accept both Spring

Pressure Clamps.

1.

Remove Back Fence from Table Surface

2.

Insert Vertical Pillar Bolt through the underside of

the Back Fence.

3.

Fit washer and screw on the Vertical Pillar. Tighten

screw securely to ensure pillar is vertical.

4.

Fit knobs to Connector Block and slide it onto

Vertical Pillar.

5.

Slide Horizontal Bar through Connector Block.

fig. S

Vertical

Pillar Bolt

Vertical

Bar

Connector

Block

Knob

Washer

Horizontal

Bar

Retaining

Screw

Pressure

Strip

3mm

Allen

Key

4mm

Allen Key

Slot

Spring Pressure Clamp Set - CRT/10

6.

Slide Pressure Strip into the slot in Horizontal Bar

aligning the holes. Insert the Retaining Screw

ensuring it goes in through the un-threaded side of

the hole first.

Before tightening the Vertical Pillar Bolts, ensure that

the Vertical Pillar will allow the block to be positioned

parallel to the Back Fence with the knob engaging on the

flat of the Vertical Pillar.

Adjustment

The Spring Pressure Clamps will require adjusting to

suit the height and width of material being routed. The

Pressure Strips should provide enough pressure to

prevent the material lifting from the Table Surface, but

not too much as to create friction which would prevent the

material from sliding freely. The block assembly with

Horizontal Bar and Pressure Strip can be removed

from the Vertical Pillars when not required. The Vertical

Pillars can be left in position and will not impede the

Tenon Push Block system.