User guide

Table Of Contents

- IMPORTANT SAFETY INSTRUCTIONS

- Important Installation Instructions Ds4020/Ds 4020H/Ds & 4020HX (only)Gate operation

- Pad and Operator Location

- Important Installation Instructions for the DST 4520 0nly

- Gate operation

- Pad and Operator Location

- Concrete Pad Construction and Layout

- Operator Mounting

- Universal gate arm Installation Guidelines

- Arm Installation

- Initial Limit Adjustment

- Pipe Connection

- Dorene DGC2000 Controller

- Power Connection / Electrical Hookup115 Volt Single PhaseSee figure 10

- Mag-Lock installationIf a 115 volt lock is used, connect the neutral wire from the lock to port #7 and the power wire from thelock to port #6

- Final Limit Adjustment

- DGC – 2000 Controller Settings

- Hand

- Close Timer

- Reverse Delay

- Close Delay

- Motor Run Timer

- Sensitivity Adjustment

- Warning Alarm

- To Hold Gate Open

- JP-3

- Led enable switch

- Final Assembly

- Blue Box formatAll Commands are dry contact, except JS4 & JS8

- JS1

- JS2

- JS3

- JS4

- JS5

- JS6

- JS7

- JS8

- JS9

- JS10

- Jp3

- Jp4

- Shadow loop Installation

- SychronousOPEN/CLOSE OPERATIONDGC 2000

- Double Swing gate loop placement

-

- Final Check

- Maintenance

- Safety Accessories

- Installation

- Testing

- Warning

- Caution

- Troubleshooting

- The left LED’S

- The Right LED’s

- Gate will not open or operate

6

IMPORTANT INSTALLATION INSTRUCTIONS

DR 3020/DR 3020HX/DRT 3520

GATE OPERATION

e gate must roll freely with no binding of the wheel, guides, and/or gate hardware before any operator is

connected to the gate.

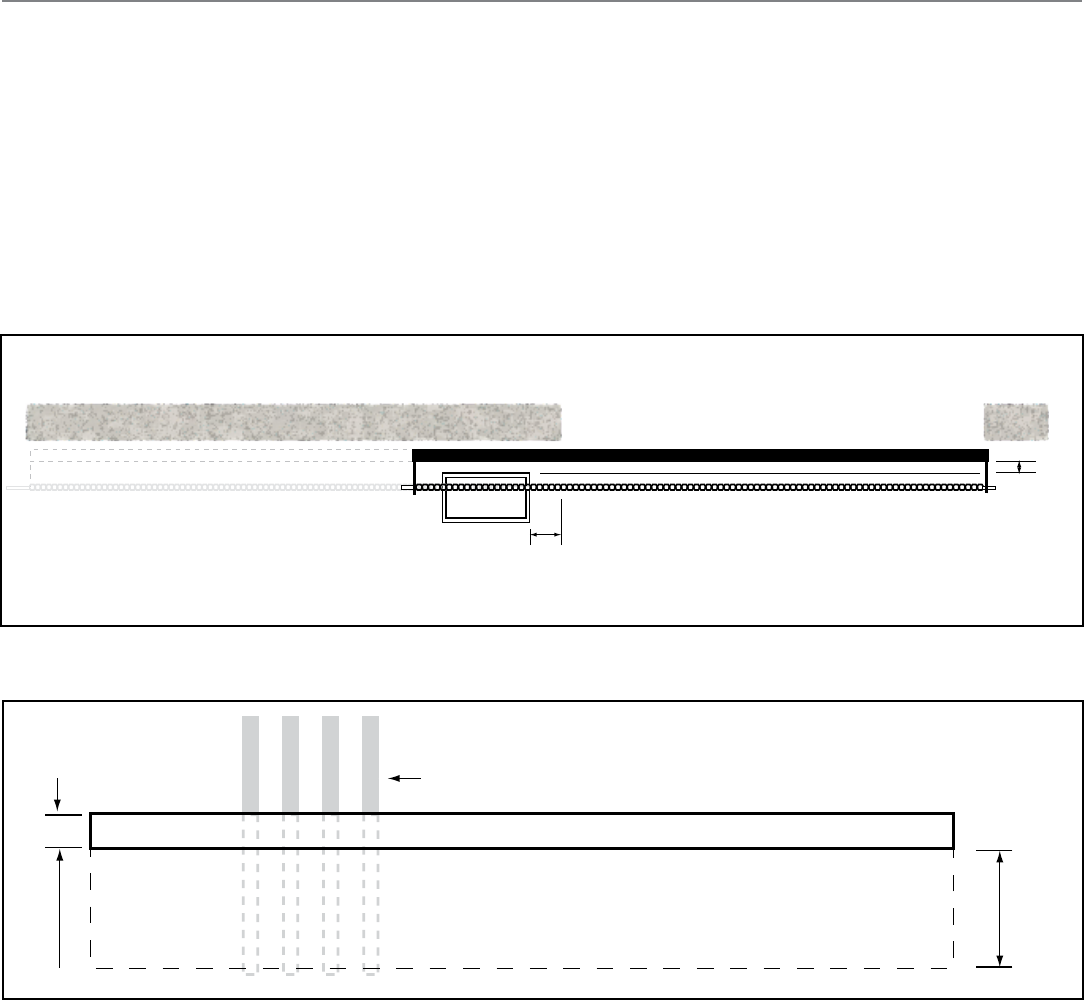

PAD AND OPERATOR LOCATION

Position the pad as indicated in Figure #1. Failure to do so may cause erratic operation resulting in reduced

operator life.

Important: If the gate is not at least twenty-eight inches longer than the opening, an extension should be added

to the rear portion of the gate r the mounting of the rear chain bolt bracket. See Fig #2 e

extension must be rigid and long enough to allow the gate to fully close without the rear chain bolt

bracket hitting the operator.

Note: If there is already concrete where the operator is to be mounted, a pad is not necessary, if the existing

concrete is level.

Gate Closed Position

4”

1”

Concrete Pad

DR 3020 / DR 3020HX / DRT3520

Gate Open Position

Figure 1 (Front Mount)

Concrete Pad Construction and Layout

18” Min.

Electrical Stub Ups

Y

Figure 2 (Side View)

Y dimension in Figure 2 must be high enough so that water will not stand under the operator in a worst case

scenario.

Soil conditions may vary but in sandy or loose soil the pad should be at least 18”-24” inches deep.