User guide

Safety

information

Product

information

Mechanical

installation

Electrical

installation

Getting

started

Basic

parameters

Running the

motor

Optimization NV Media Card

Advanced

parameters

Technical

data

Diagnostics

UL listing

information

112 Unidrive M100 User Guide

Issue Number: 1

11.1.3 Supply requirements

AC supply voltage:

100 V drive: 100 V to 120 V ±10 %

200 V drive: 200 V to 240 V ±10 %

400 V drive: 380 V to 480 V ±10 %

Number of phases: 3

Maximum supply imbalance: 2 % negative phase sequence (equivalent

to 3 % voltage imbalance between phases).

Frequency range: 48 to 62 Hz

For UL compliance only, the maximum supply symmetrical fault current

must be limited to 100 kA

11.1.4 Line reactors

Input line reactors reduce the risk of damage to the drive resulting from

poor phase balance or severe disturbances on the supply network.

Where line reactors are to be used, reactance values of approximately

2 % are recommended. Higher values may be used if necessary, but

may result in a loss of drive output (reduced torque at high speed)

because of the voltage drop.

For all drive ratings, 2 % line reactors permit drives to be used with a

supply unbalance of up to 3.5 % negative phase sequence (equivalent to

5 % voltage imbalance between phases).

Severe disturbances may be caused by the following factors, for example:

• Power factor correction equipment connected close to the drive.

• Large DC drives having no or inadequate line reactors connected to

the supply.

• Across the line (DOL) started motor(s) connected to the supply such

that when any of these motors are started, the voltage dip exceeds

20 %

Such disturbances may cause excessive peak currents to flow in the

input power circuit of the drive. This may cause nuisance tripping, or in

extreme cases, failure of the drive.

Drives of low power rating may also be susceptible to disturbance when

connected to supplies with a high rated capacity.

Line reactors are particularly recommended for use with the following

drive models when one of the above factors exists, or when the supply

capacity exceeds 175 kVA:

Model sizes 04200133 to 04400170 have an internal DC choke so they

do not require AC line reactors except for cases of excessive phase

unbalance or extreme supply conditions.

Where required, each drive must have its own reactor(s). Three

individual reactors or a single three-phase reactor should be used.

Reactor current ratings

The current rating of the line reactors should be as follows:

Continuous current rating:

Not less than the continuous input current rating of the drive

Repetitive peak current rating:

Not less than twice the continuous input current rating of the drive

11.1.5 Motor requirements

No. of phases: 3

Maximum voltage:

100 V drive: 240 V

200 V drive: 240 V

400 V drive: 480 V

575 V drive: 575 V

690 V drive: 690 V

11.1.6 Temperature, humidity and cooling method

Ambient temperature operating range:

- 20 °C to 40 °C (- 4 °F to 104 °F).

Output current derating must be applied at ambient temperatures

>40 °C (104 °F).

Cooling method: Forced convection

Maximum humidity: 95 % non-condensing at 40 °C (104 °F)

11.1.7 Storage

-40 °C (-40 °F) to +60 °C (140 °F) for long term storage.

Storage time is 2 years.

Electrolytic capacitors in any electronic product have a storage period

after which they require reforming or replacing.

The DC bus capacitors have a storage period of 10 years.

The low voltage capacitors on the control supplies typically have a

storage period of 2 years and are thus the limiting factor.

Low voltage capacitors cannot be reformed due to their location in the

circuit and thus may require replacing if the drive is stored for a period of

2 years or greater without power being applied.

It is therefore recommended that drives are powered up for a minimum

of 1 hour after every 2 years of storage.

This process allows the drive to be stored for a further 2 years.

11.1.8 Altitude

Altitude range: 0 to 3,000 m (9,900 ft), subject to the following

conditions:

1,000 m to 3,000 m (3,300 ft to 9,900 ft) above sea level: de-rate the

maximum output current from the specified figure by 1% per 100 m

(330 ft) above 1,000 m (3,300 ft)

For example at 3,000 m (9,900 ft) the output current of the drive would

have to be de-rated by 20 %.

11.1.9 IP / UL Rating

The drive is rated to IP20 pollution degree 2 (dry, non-conductive

contamination only).

In addition to this, drive sizes 2 and 3 are rated to IP21 standard (without

an Adaptor Interface module installed).

The IP rating of a product is a measure of protection against ingress and

contact to foreign bodies and water. It is stated as IP XX, where the two

digits (XX) indicate the degree of protection provided as shown in Table

11-5.

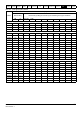

Table 11-5 IP Rating degrees of protection

First digit Second digit

Protection against contact and

ingress of foreign bodies

Protection against ingress of water

0 No protection 0 No protection

1

Protection against large

foreign bodies φ > 50 mm

(large area contact with the

hand)

1

Protection against vertically

falling drops of water

2

Protection against medium

size foreign bodies φ > 12 mm

(finger)

2

Protection against spraywater

(up to 15 ° from the vertical)

3

Protection against small

foreign bodies φ > 2.5 mm

(tools, wires)

3

Protection against spraywater

(up to 60 ° from the vertical)

4

Protection against granular

foreign bodies φ > 1mm (tools,

wires)

4

Protection against splashwater

(from all directions)

5

Protection against dust

deposit, complete protection

against accidental contact.

5

Protection against heavy

splash water (from all

directions, at high pressure)

6

Protection against dust

ingress, complete protection

against accidental contact.

6

Protection against deckwater

(e.g. in heavy seas)

7 - 7 Protection against immersion

8 - 8 Protection against submersion