Specifications

Table Of Contents

- Imprint

- Documentation Representative

- © HYDAC FILTER SYSTEMS GMBH

- Contents

- Preface

- Safety information

- Storing the CS

- Decoding the model code label

- Checking the scope of delivery

- CS1000 Features

- CS1000 Restrictions on use

- CS1x1x dimensions (without display)

- CS1x2x dimensions (with display)

- Hydraulic connection types

- Fastening / mounting the CS1000

- Display rotatable/Adjustable As Needed

- CS1000 hydraulic installation

- Electrical connection of the CS1000

- Setting the measuring mode

- Operating the CS1x2x using the keypad

- Overview of menu structure

- Using switching output

- Setting limit values

- Reading the analog output

- Status Messages

- Connecting CSI-D-5 (Condition Sensor Interface)

- Connecting the CS1000 to an RS-485 bus

- Communicating with the CS1000 via the RS-485 bus

- Taking the CS1000 out of operation

- Disposing of CS1000

- Spare Parts and Accessories

- Cleanliness classes - brief overview

- Checking/resetting default settings

- Technical data

- Recalibration

- Customer Service

- Model Code

- EC declaration of conformity

ContaminationSensor CS 1000 CS1000 hydraulic installation

HYDAC FILTER SYSTEMS GMBH

en(us)

Page 23/112

BeWa CS1000 3764916 300 en-us 2012-08-29.doc 2012-08-29

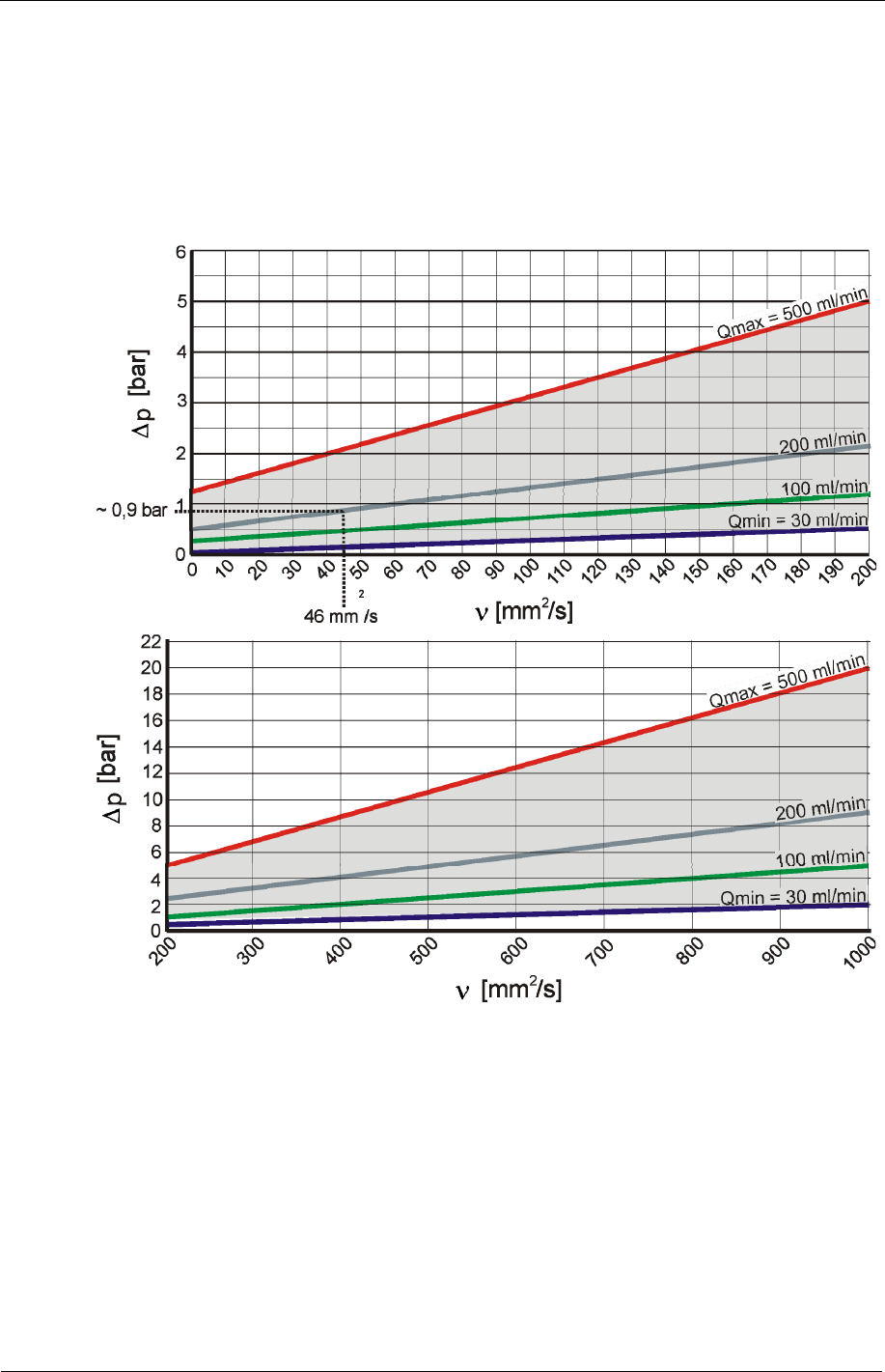

Flow rate, differential pressure

p

and viscosity

characteristics

Differential pressure

p

and viscosity

characteristics. All the values indicated in

the figures below apply regardless whether the direction of flow is A->B or B->A.

Note that the permissible measured volumetric flow is 30 … 500 ml/min.

If you are unable to achieve the required flow values, we offer an extensive line of

accessories with various conditioning modules.

For example:

You are using a fluid with a viscosity

of 46 mm²/s at a pressure difference

p

of

~0.9 bar, so that you achieve a flow rate of approx. 100 ml/min.

The flow rate depends on the viscosity of the medium and the differential pressure

p

via the sensor.