Maintenance Instructions

10044S

Colt Canada Proprietary 4-4 2005-09-20

e. Move the bolt in and out to check for

binding in the bolt carrier; and

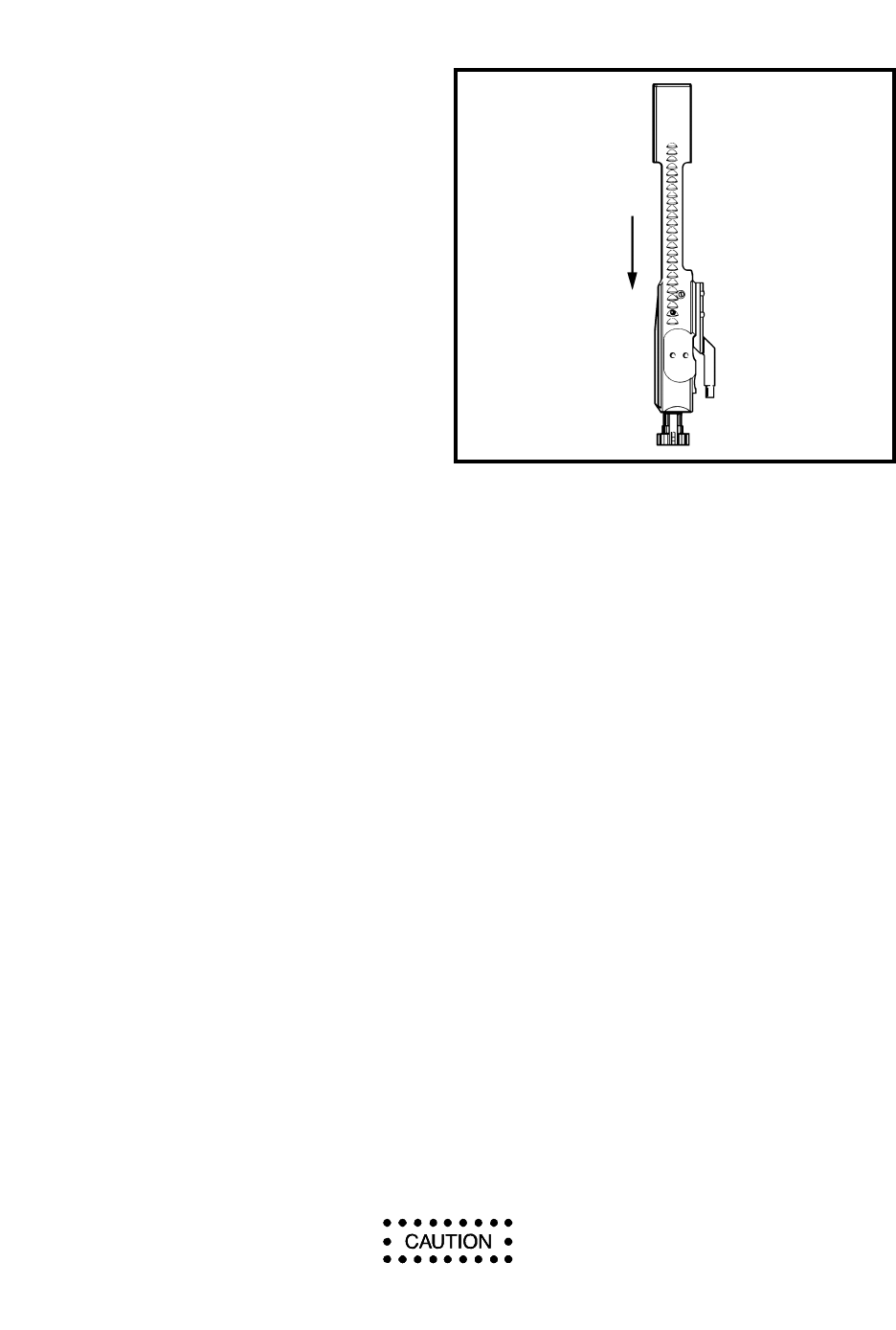

f. Hold the bolt carrier with the bolt

facing downward. See Figure 4-6.

10. The bolt shall not drop out of the bolt

carrier on its own weight. If the bolt drops out,

replace all three bolt rings.

RETURN SPRING LENGTH

11. See Table of Specifications for

approximate return spring lengths.

12. Replace Defective Springs. DO NOT

attempt to adjust spring length by stretching the

spring.

HAMMER AND TRIGGER AXIS PIN HOLE WEAR

13. Gauge the diameter of the hammer and trigger axis pin holes from both sides of the

receiver with the “NOT GO” plug gauge. If the “NOT GO” gauge passes completely through the

receiver wall the axis pin hole is no longer serviceable. Backload weapons failing this test.

NOTE

Hammer and trigger axis pin holes shall only be gauged if the trigger mechanism has

been removed for other work, if there is side play evident in the trigger mechanism or if

the weapon malfunctions and the trigger mechanism is suspect.

TRIGGER PULL

14. Check the trigger mechanism for cleanliness and smooth operation. Test trigger pull by

the following procedure:

a. Cock the weapon and move the fire control selector to the “R” position;

b. Place a trigger test scale on the trigger and apply a steady pressure in line with the bore

of the weapon; and

c. Note the weight at which the trigger releases the hammer.

15. The trigger pull shall be between 2.26 and 3.85 kg (5 and 8-1/2 lb). Adjust trigger pull by

exchanging parts in the trigger mechanism as required.

DO NOT adjust trigger pull by altering the shape or dimension of the sear or hammer

bents.

Figure 4-6 Bolt Ring Wear Test