Maintenance Instructions

10044S

Colt Canada Proprietary 4-2 2005-09-20

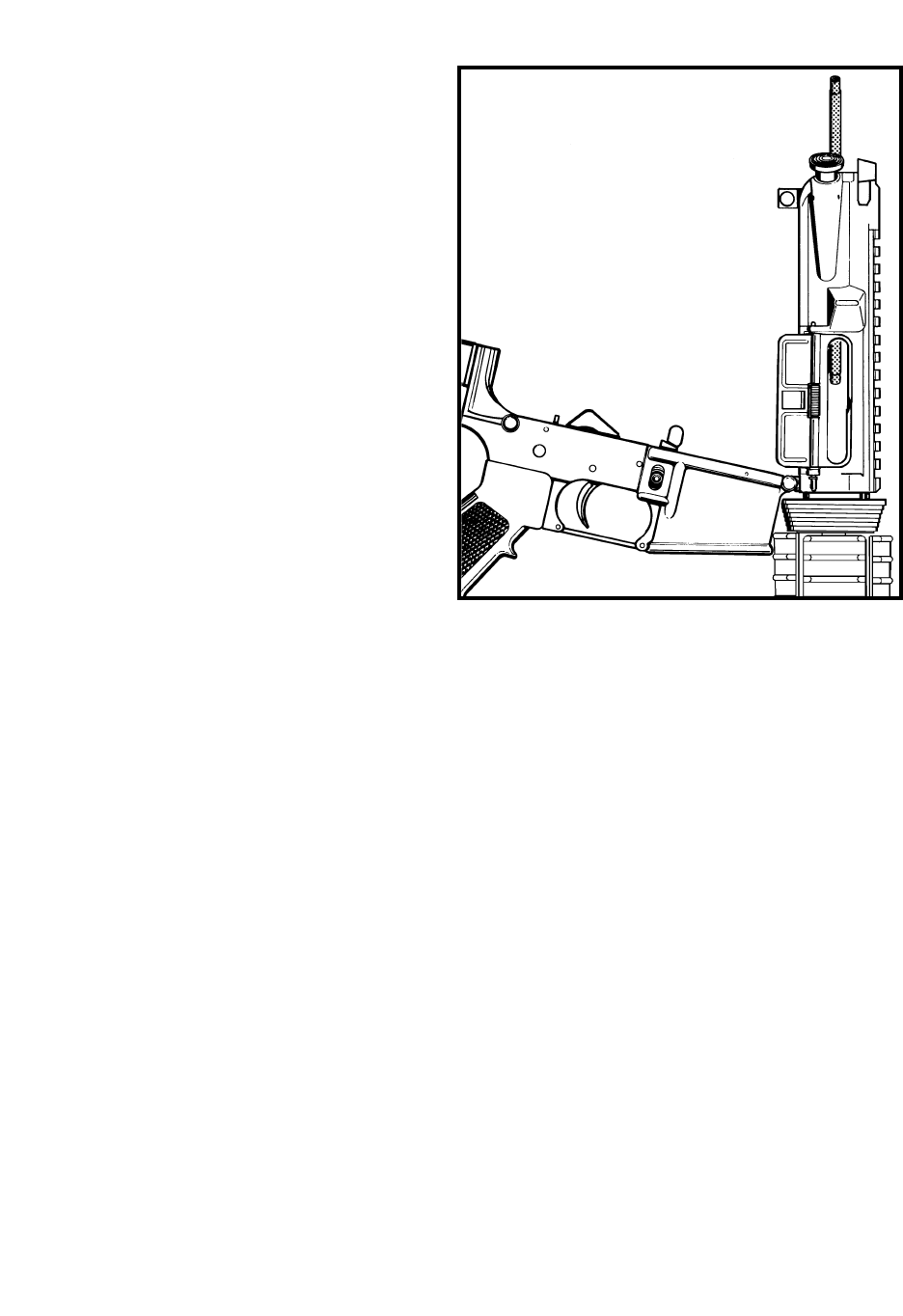

a. Break open the weapon and remove

the bolt carrier group;

b. Thoroughly clean the bore and 5.49

mm bore straightness “GO” gauge;

c. Hold the weapon over a work bench

with the barrel vertical; and

d. Insert the gauge into the barrel from the

breech end. See Figure 4-3.

NOTE

DO NOT allow the gauge to fall onto a hard

surface.

6. The gauge shall pass freely through the

barrel. Clean and retest weapons failing to

pass the gauge freely.

a. Using a commercial chemical fouling

remover, brush out the fouling with the

bore brush in accordance with normal

cleaning procedures;

b. Repeat as necessary; and

c. Inspect bore for straightness using barrel straightness gauge 8576410-1.

HEADSPACE

7. See Figure 4-4. The headspace dimension (1) is the distance between the face of the

cartridge seat of the bolt (2) and the datum diameter (3) of the cone at the front of the chamber.

Headspace for the C7 and C8 weapons shall be between 37.10 and 37.42 mm. Check

headspace with the “GO” and “NOT GO” headspace gauges by the following procedure:

a. Separate the upper receiver and barrel group from the weapon;

b. Withdraw the bolt carrier group far enough to allow the headspace gauge to be positioned

in the chamber;

c. Insert the headspace gauge into the chamber; and

d. Push the bolt carrier group forward with a slight, steady finger pressure.

8. The bolt shall close and lock over the “GO” headspace gauge. It shall not lock over the

“NOT GO” headspace gauge. See Figure 4-5. If the weapon does not pass the test, retest it with

a known serviceable bolt assembly to determine the source of the problem. If after retesting with

Figure 4-3 Testing Bore Straightness