Maintenance Instructions

10044S

Colt Canada Proprietary 3-2-55/3-2-56 2005-09-20

b. Ensure that the front sight protectors are not bent or cracked, and that the front sight post

is secure;

c. Inspect the barrel to ensure that it is straight, free from fouling or other obstruction, and

meets gauging requirements. Rifles which show evidence of erosion at the commencement

of rifling (C of R) should be range tested for accuracy and incidents of keyholing;

d. Ensure that the chamber is free of roughness or burrs, and that the chromium plating is

intact;

e. Inspect all parts of the gas system to ensure that carbon deposits are removed and vent

holes are clear, and that the gas tube aligns with the carrier key.

f. Inspect the handguards for cracks or chips, and ensure that the two half sections fit together

properly. Check also for gaps or sharp edges which could cause injury to the hands;

g. Ensure that the positive retention of the back sight in each position;

h. Ensure that the rear sight protectors are not bent or cracked; and

j. Ensure that the ejection port cover is held closed by its latch.

BOLT CARRIER GROUP

89. Check the bolt carrier group serviceability as follows:

a. Inspect the extractor for wear or chipping;

b. Inspect the bolt carrier for fractures or burrs; and

c. Ensure that bolt carrier key screws are tight and properly staked.

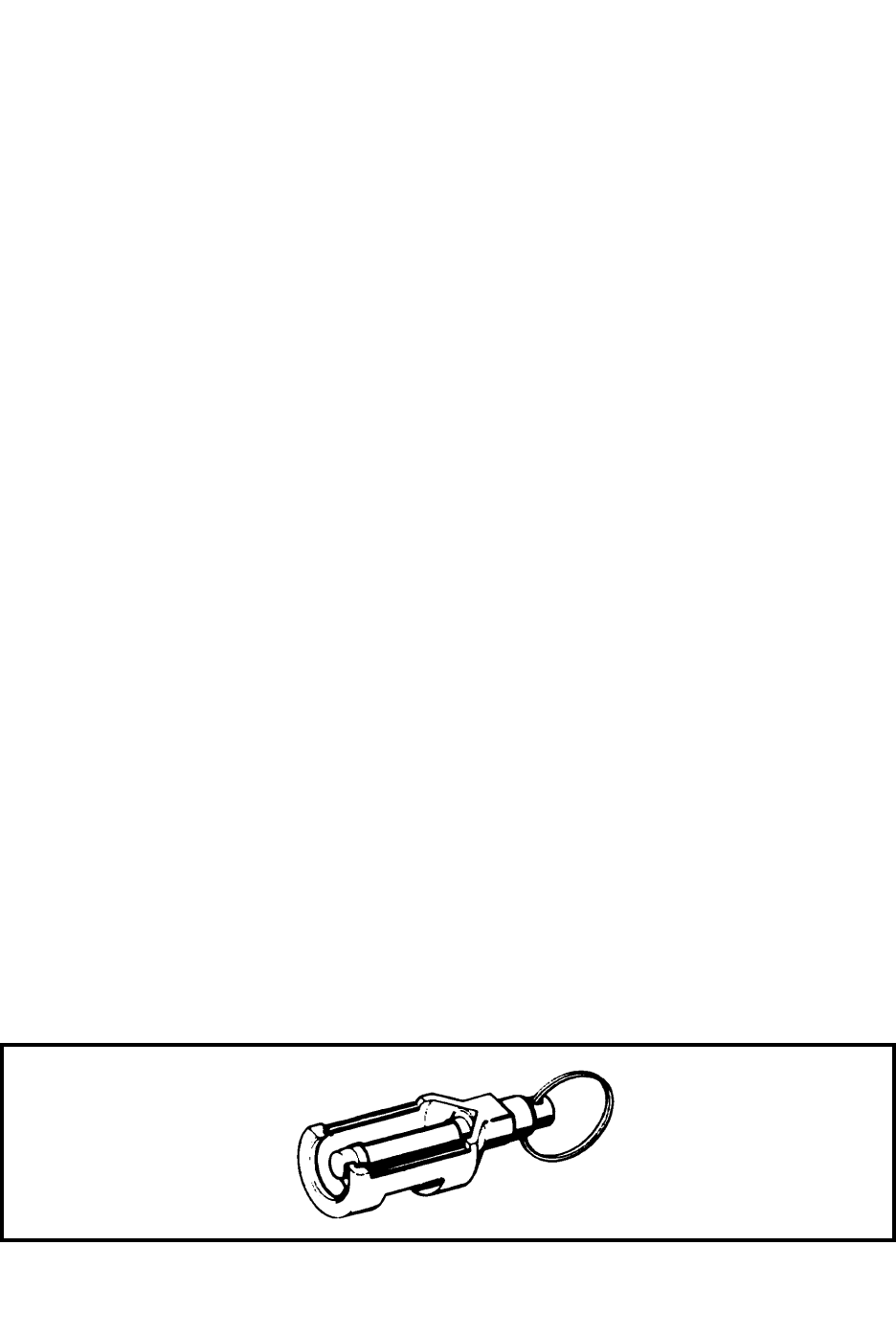

BLANK FIRING ATTACHMENT

90. The blank firing attachment shall be maintained in serviceable condition so that it may be

securely fastened to the compensator. The blank firing attachment with the exception of the

threads, shall be painted with yellow or red, heat resisting enamel for identification purposes.

See Figure 3-2-69.

Figure 3-2-69 Blank Firing Attachment