Maintenance Instructions

10044S

Colt Canada Proprietary 3-2-12 2005-09-20

c. Gas Tube. Ensure that the gas tube is free of deformation, cracks and carbon deposits;

d. Compensator. The compensator shall be free of burrs, cracks or dents. Check the

compensator spacer to ensure that the laminations are uniform with no protruding sharp

edges which could present an injury hazard;

e. Front Sight. Ensure that the front sight post is not burred or distorted. Check the spring

to ensure that it is not kinked or corroded. Check the detent for correct form and function;

f. Barrel Nut Assembly Components. Ensure that the slip ring is not cracked, burred or

distorted and that it effectively secures the handguards. Check the slip ring spring to

ensure that it is not kinked or broken and that it holds the slip ring forward under uniform

pressure. Check the condition of the snap ring; ensure that it retains the slip ring spring

effectively. Ensure that the barrel nut is not cracked, burred or distorted, and that the

threads are not damaged; and

g. Barrel Assembly. Inspect the barrel assembly for the following:

(1) Security and correct form of the front sight;

(2) Security and correct form of the barrel indexing pin;

(3) Cracks, rust, bulges or pitting in the bore;

(4) Amount of gilding (coppering) of the rifling, as denoted by the darkness of the lands;

and

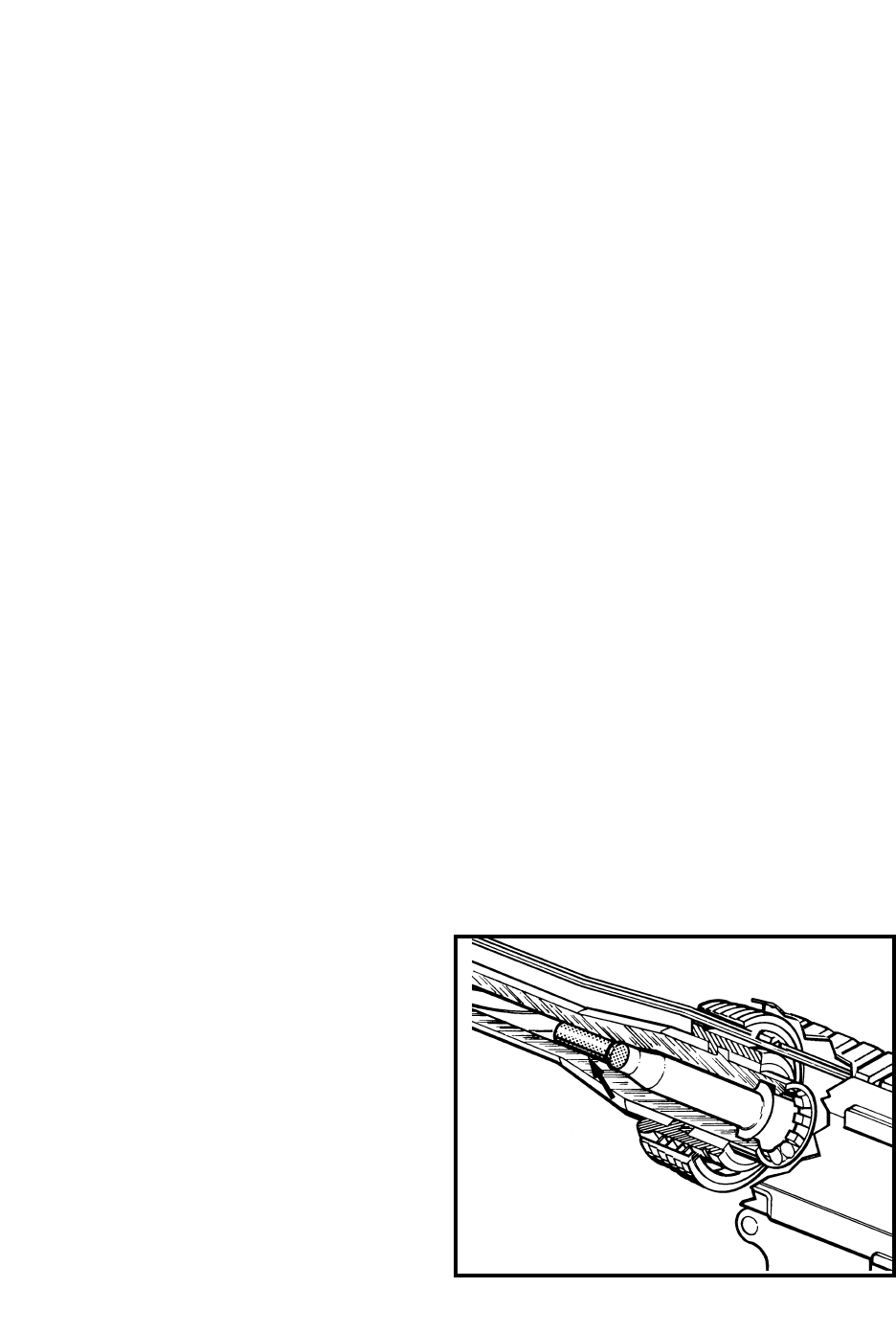

(5) Condition of the chamber, determined by using the reflector tool. See Figure 3-2-20.

NOTE

If doubt exists as to the serviceability or accuracy of the barrel, test it as detailed in

Part 4 - Tests and Adjustments, of this instruction.

REPAIRING THE BARREL ASSEMBLY

9. Repair the barrel assembly

components by the following procedures:

a. Handguard Assemblies. Replace

defective handguard assemblies, and

RAS parts.

b. Gas Tube Assembly. Remove carbon

from the exterior of the gas tube as

required to facilitate reassembly.

Replace gas tube assemblies that are

restricted with carbon, have worn

furrels, or are otherwise defective.

Figure 3-2-20 Inspecting the Chamber