Operating instructions

EC3 Series

Coldroom Controllers

D A T A S H E E T

EC3-3_35041_EN_R13.docx 5 / 8 23.02.2012

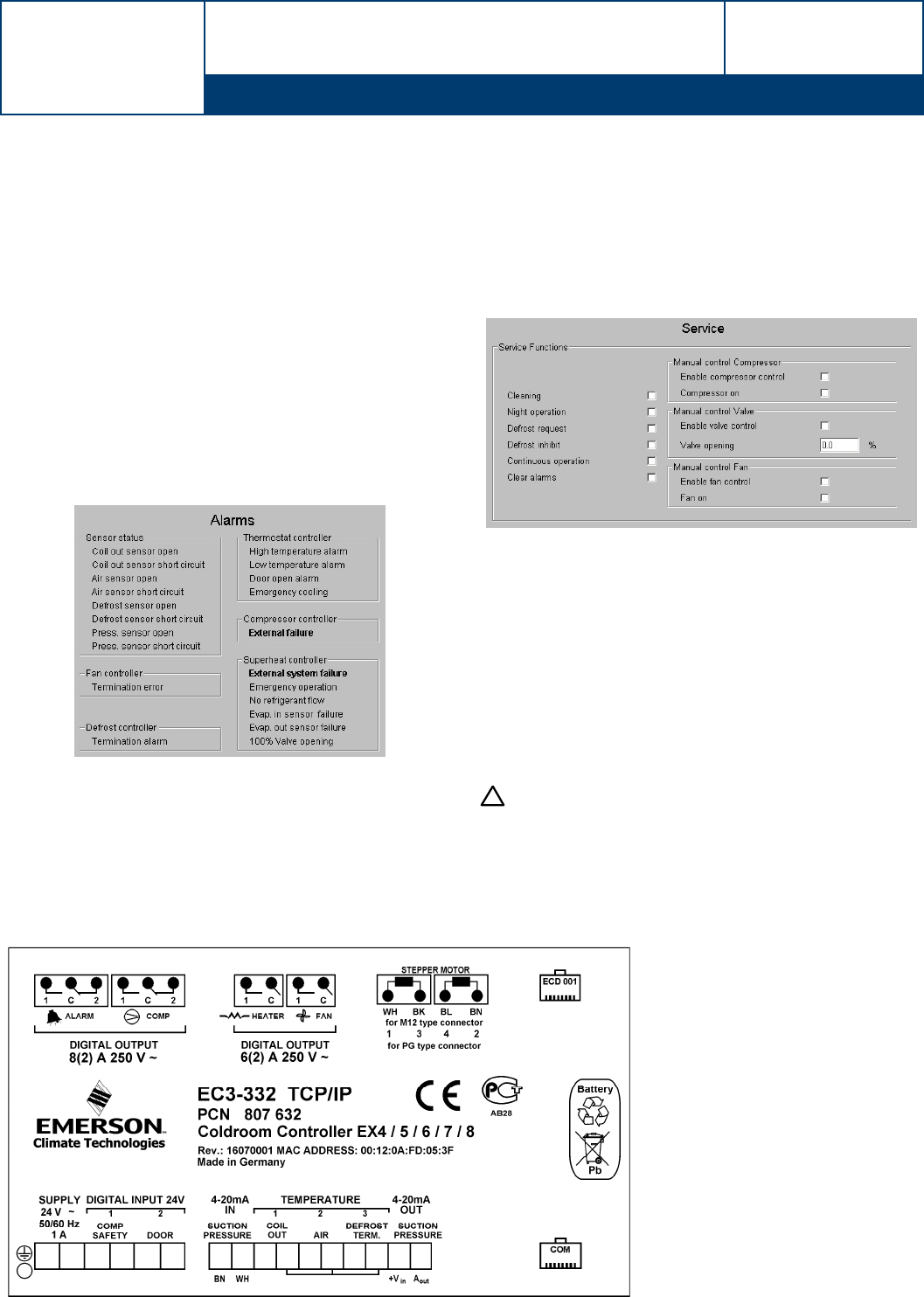

Alarm and Maintenance Functions

EC3-33x provides many alarm codes to facilitate diagnosis.

Limit violation alarms are associated with temperature and

pressure set point (high alarm, low alarm, sensor failure).

The serial alarm loop of the compressor can be connected to a

digital input. It will monitor compressor operation and signal

shutdown in case the serial alarm loop is open due to high

motor temperature or excessive pressure etc.

Alarm management includes the issuing of an alarm message

through the network and to show the alarm code on the

controllers display. The priorities and subsequent actions can

be individually defined for each alarm when connected to a PC

or an AMS monitoring server.

The EC3-332 has the capability to send alarm messages

directly by email.

While the attached Display Unit ECD-001 indicates alarms as

blinking symbols only, the monitoring WebPage shows all

alarms in text form. All possible alarm messages are visible,

active alarms are highlighted bold, see below:

Safety Functions

Various safety functions are available for use particularly when

the EC3-33x is controlling the compressor directly. These safety

features are used to prevent compressor damage and include:

Limitation of maximum evaporating pressure (MOP), delay of

compressor start after control reset, minimum time between two

starts, minimum compressor off time, minimum compressor run

time.

Safe operating modes allow the system to continue to operate

safely even when the signal is lost from a defective or

disconnected sensor.

Particularly useful facilities are the service functions, which

enable the engineer to manually control the system during

commissioning. They include manual operation of compressor,

fan and Electrical Control Valve, or special operating modes of

system for cleaning, permanent night operation, manual defrost

or others, see below:

In event of power failure to the entire system, the stepper motor

driven valve would not be able to move. Due to the differential

pressure between condenser and evaporator, the refrigerant

could continue to flow through the valve if the valve is open.

The compressor must be protected after power recovery

against wet running. EC3-33x contains an internal rechargeable

battery and smart battery charge control to automatically close

the valve in case of power failure. Whilst the battery is

maintenance free, the life expectancy will depend upon the

working ambient; as the temperature increases the life

expectancy reduces.

It is recommended to replace the battery annually to maintain

the system in optimum operating condition.

If the alarm relay is not utilized, the user must ensure

appropriate safety precautions are in place to protect the

system against damage caused by a power failure.

Wiring Diagram

EC3-33x Coldroom Controller for Electrical Control Valves EX4 … EX8

!