Operating instructions

EC3 Series

Coldroom Controllers

D A T A S H E E T

EC3-3_35041_EN_R13.docx 3 / 8 23.02.2012

Defrost

EC3-33x Series controllers allow local defrost management

through the built-in defrost timer but also permit remote defrost

scheduling through the networking connection. For remote

defrost details please consult the operating instructions.

Two basic defrost modes are possible:

Electrical / hot gas defrost

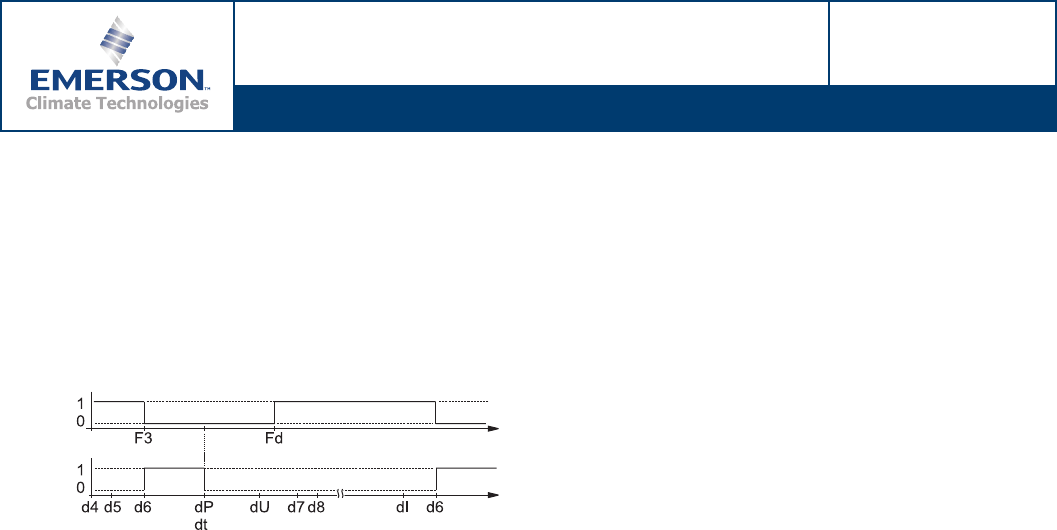

All timing parameters can be selected to cover specific defrost

modes, see the diagrams below for the function of defrost

output and fan output at defrost:

Fan

Defrost

Defrost can be activated after power up (d4 flag) and the delay

(d5). Delay (d6) allows for pump down. The defrost will end

either when the defrost termination temperature (dt) has been

exceeded or after the maximum defrost duration (dP). Other

delays take care for synchronization of multiple evaporators in

the same system (dU), for drain (d7) and for injection (d8). The

next defrost will occur after the specified defrost interval (dI).

Fans can be switched off at defrost (F3 flag) and switched on

after defrost and drip time delay (Fd).

End of defrost is detected by the dedicated defrost temperature

sensor ECN-F60.

Natural Defrost

Though natural defrost is possible with the EC3-33x Series, it is

unlikely that such a defrost method is used in a coldroom. Since

the EC3-33x Series is also applicable for other refrigeration

applications, natural defrost may well be applicable there.

Sensors

Low cost NTC sensors are available with different cable lengths

to meet specific customer's requirements for optimal positioning

of the sensors. All sensors are hermetically sealed for high

reliability and long life. Air sensors have a plastic housing, pipe

and fin sensors have metal housings for optimal thermal

conductivity and the fin sensor has an additional mounting clip.

Operation and Commissioning

Operating and commissioning of an EC3-33x Controller may be

performed by using one of the following options:

- Locally or remote with a PC connected to the TCP/IP Ethernet

port of the EC3-332.

- Remotely via the AMS Server connected to the LON

®

port of

an EC3-331.

- Locally through the 4-button keypad of an optional ECD-001.

For initial commissioning of a new installation depending on the

networking technology of the EC3-33x the first two options are

the most appropriate. Commissioning is done via dedicated

menus with meaningful default values, which make

commissioning an EC3-33x a plug-and-play type of job.

Anybody who is familiar with Microsoft Windows

®

based

programs and WebBrowsers should find it very intuitive without

the need for special training.

Optional ECD-001 Display Unit

The ECD-001 may be attached to the EC3 Series Controller to

provide a local display of system parameters, most commonly

temperatures. With the 2½ digit display temperatures within

±199°C can be shown with a resolution of 1°C. The resolution

improves to 0.1°C within a range of ±19.9°C. The display unit

can be switched from °C to °F. When displaying °F the same

resolution as above applies.

Indicator LEDs show the status of compressor, fan, defrost and

alarm. A blinking LED indicates that the EC3 Controller is trying

to fulfill a task but is prevented from doing so by another

restraint in the system. An example of this would be the

minimum compressor run time.

WebServer function of the EC3-332 with TCP/IP Ethernet

networking capabilities

Though the actual status of the controllers can be viewed on

the optional ECD-001 Display Unit, it is much more convenient

to do the viewing on a PC. All relevant parameters and modes

are visible on a single WebPage simultaneously. For even more

details and for setup and maintenance a click on one of the

screen tabs calls up a WebPage dedicated to specific task. All

of this can be done with a standard WebBrowser like the

Internet Explorer

®

, the Mozilla Firefox or others. The picture on

page 4 shows the homepage of an EC3-332 with the monitoring

WebPage of the controller.

Echelon LON

®

Networking Capabilities of the EC3-331

The remote access, viewing and monitoring features of the

LON

®

version EC3 Series Controllers match and exceed the

capabilities of their TCP/IP counterparts. Though remote access

requires the use of the EMS Monitoring Server or special third

party LON

®

compliant hardware and software, many more

additional functions and features are available.

The EC3-331 Controllers are equipped with LON-FTT10 (free

topology) transceiver types. This offers the installer greatest

flexibility in the way the controllers are connected to the LON®

network in addition to offering higher communication

transmission rates.

When connected to the LON

®

network, the individual EC3

Series controllers may be bound together through peer-to-peer

communication to form self-contained control loops for

applications such as synchronised defrosting.

Retrieval and download of setups and data is very comfortable

and easily achievable in LON

®

systems.

Refer to the "Alco Networking Application" sheets for further

details.

Where to apply TCP/IP Ethernet vs. LON

®

Controllers

In general TCP/IP Ethernet controllers are more applicable for

smaller refrigeration systems with only a few pieces of

refrigeration equipment. No special hardware or special

software is needed and whoever can set up a small PC network

has all the necessary know-how to set up and operate EC2 and

EC3 TCP/IP Ethernet controllers.

In larger installations LON

®

has its merits. Network wiring is

easier and less costly. Peer-to-peer communication is another

benefit of LON

®

and data retrieval and storage are very easily

achievable. These advantages come at a price however: a

monitoring and server device like the EMERSON EMS is

needed along with some special know-how in LON

®

technology. The associated cost therefore makes LON

®

technology primarily applicable in large refrigeration plants with

many pieces of refrigeration equipment like Supermarkets or

large cold storage facilities.