Operating instructions

EC3 Series

Coldroom Controllers

D A T A S H E E T

EC3-3_35041_EN_R13.docx 2 / 8 23.02.2012

Introduction

The EC3-33x series Controllers are for use in commercial

refrigeration systems, primarily to control the refrigeration circuit

of coldrooms. This includes the control of the refrigerant flow to

optimize superheat, maintain air temperature and the defrost

management. Alco Controls EX4…EX8 Electrical Control

Valves must be used in conjunction with the EC3-33x units to

modulate refrigerant flow.

Two separate control loops are coordinated in the device: one

senses evaporating pressure and temperature to maintain

optimum superheat, while the other loop controls air temperature.

Other functions include the management of defrost schedules

and sequences, data monitoring and alarm handling. Though

EC3 Controllers can operate as stand alone devices, they are

best suited to networked solutions, which take advantage of the

monitoring capabilities.

The EC3-33x Controllers are members of the range of EC2 and

EC3 devices, which can be easily assembled into complete

control systems for commercial refrigeration. They all share the

benefits of remote access and data communication. Please

refer to specific datasheets for details.

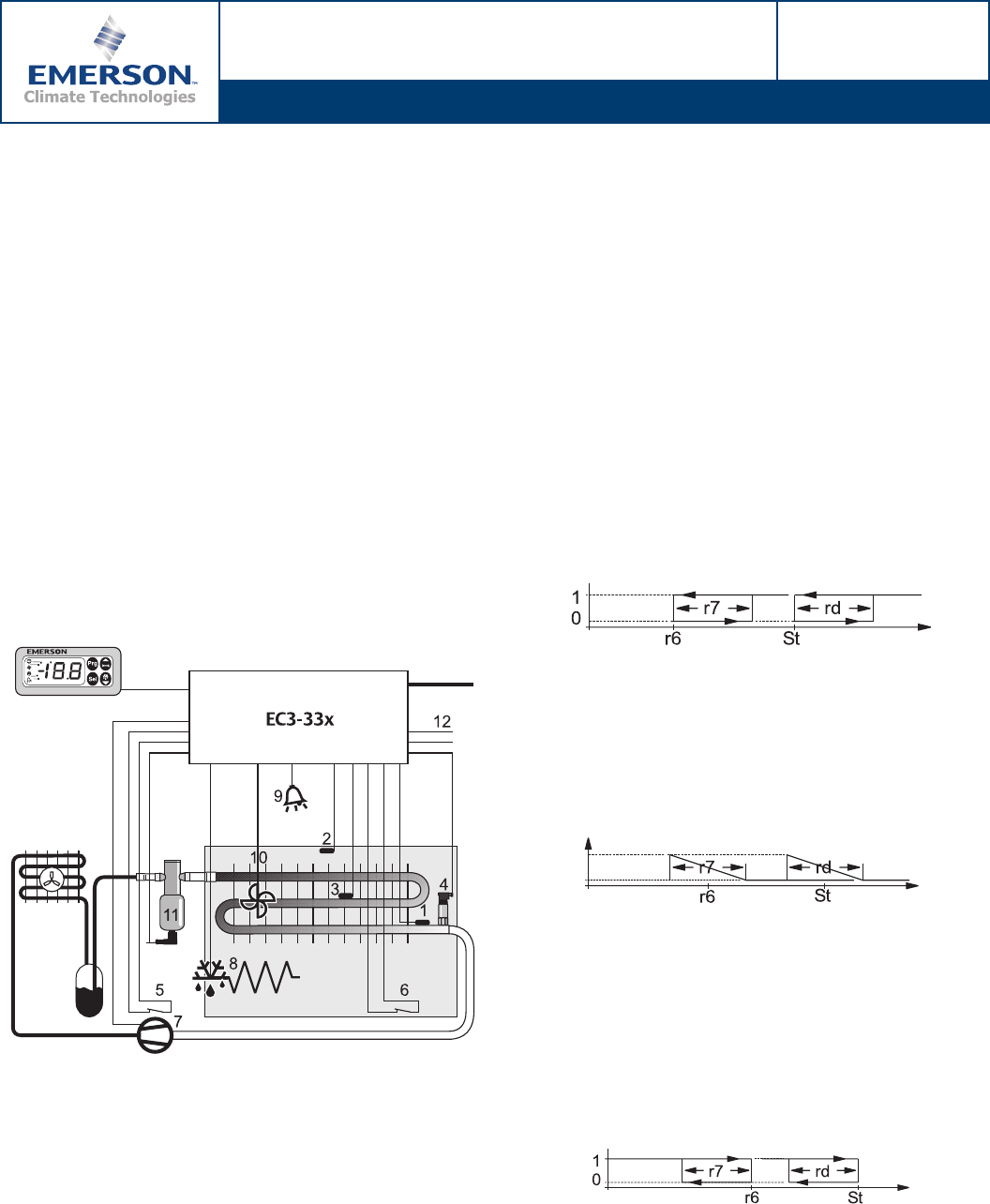

Application

The functions of the EC3-33x Controllers are described in the

functional diagram below:

With coil out temperature (1) and evaporating pressure (4) the

superheat is calculated to define the opening of the Electrical

Control Valve (11). Superheat can be set to a fixed value or an

adaptive mode may be used. Temperature sensor (2) is part of

the temperature control loop. The defrost heater (8) can be

activated locally by fixed timing intervals or remotely through the

communications port. For defrost end termination the

temperature sensor (3) can be used. Fan (10) and compressor

(7) are controlled as well. One digital input is allocated to the

compressor safety loop (5). Another digital input monitors the

door switch (6), which will activate an alarm if the door is not

closed within a specified time. The analog output (12) feeds the

evaporating pressure transmitter signal to a 2

nd

EC3-33x or

other Controller on the same suction line thus eliminating the

need for a second pressure transmitter.

In case of power loss a battery built in the EC3-33x will close

the Electrical Control Valve (11) and avoid flooding of the

compressor. Due to the positive shut-off capabilities of the EX4

… 8 valves a separate liquid line solenoid valve is not required.

Superheat Control

The EC3 Series controls evaporator superheat by varying the

mass flow through the Electrical Control Valve (ECV). The

controller automatically calculates the number of steps required

for the correct valve opening by measuring pressure and

temperature at the evaporator output. PT5-07M pressure

transmitters and ECN-Pxx pipe type temperature sensors from

EMERSON must be used.

The controller works in two operating modes: fixed superheat

and adaptive superheat. In the “fixed” mode, the superheat

set-point is fixed to a user-defined value. In the “adaptive” mode

the controller varies superheat set-points in the range between

3K

and 15K depending on system conditions to maintain stable

operation. The pressure drop through a distributor or the glide

associated with certain refrigerants (e.g. R407C) can be

compensated in the controller.

Temperature Control

The ECN-Sxx air sensor is used for temperature control of the

coldroom. The dead band control function is described in the

diagram below:

The horizontal axis represents the temperature, with St the set-

point for day operation and rd the difference at day, while r6 is

the set-point for night operation and r7 the difference at night.

The vertical axis represents cooling operation (1 = cooling, 0 =

no cooling).

A control parameter allows to switch off the evaporator fan

during “no cooling”.

A more precise temperature control can be achieved by using

the modulating temperature mode as shown below:

The horizontal axis represents the temperature, the vertical axis

the superheat setting. At high temperatures, the controller

works with minimum superheat. St is the set-point for day

operation, at which the superheat is already increased. rd

specifies the proportional band in which the superheat is

modulated. Equivalent is r6, the set-point for the night operation

and r7 the width of the proportional band at night. At a

temperature of St minus ½*rd (day) or r6 minus ½*r7 (night) the

valve is closed.

In case the controller should be used in a heat pump for

heating, the function of the temperature controller can be

inversed:

When used with a standard condensing unit, the compressor

relay can be used to switch the coil of power contactor. The

compressor relay is not used in a refrigeration system with a

rack controller. In this application, the electrical control valve

closes when the thermostat set-point has been reached and the

rack will automatically pump down if there is insufficient demand

from the rest of the refrigeration system.