User`s manual

Table Of Contents

- 535 User's Manual

- Table of Contents

- Chapter 1: Introduction

- Chapter 2: Basic Interface

- Chapter 3: Installation

- Chapter 4: Hardware Set Up

- Chapter 5: Software Configuration

- Chapter 6: Tuning

- Chapter 7: Applications

- Control Type

- Alarms

- Duplex Control

- Slidewire Position Proportioning Control

- Velocity Position Proportioning Control

- Staged Outputs

- Retransmission

- Digital Inputs

- Remote Setpoint

- Multiple Setpoints

- Multiple Sets of PID Values

- POWERBACK

- Self Tune–POWERTUNE®

- Ramp-To-Setpoint

- Input Linearization

- Load Line

- Security

- Reset Inhibition

- Process Variable Reading Correction

- Serial Communications

- Cascade Control

- Ratio Control

- Appendix 1: Menu Flowcharts

- Appendix 2: Parts List

- Appendix 3: Troubleshooting

- Appendix 4: Calibration

- Appendix 5: Specifications

- Appendix 6: Glossary

- Appendix 7: Isolation Block Diagram

- Return Procedures and Warranty Information

- 500 Series Process Controllers User's Manual

535 User's Manual Chapter 7 103

Applications

V. RATIO CONTROL

Ratio Control is employed in mixing applications that require the materials to

be mixed to a desired ratio.

For example: A given process requires Material A to be blended with Material

B in a 2:1 ratio. Material B is uncontrolled or wild. Flow sensors/transmitters

are used to measure the flow rate of each stream. The flow signal for Material

A is wired to the process variable input, and the flow signal for Material B is

wired to the remote setpoint input of the 535.

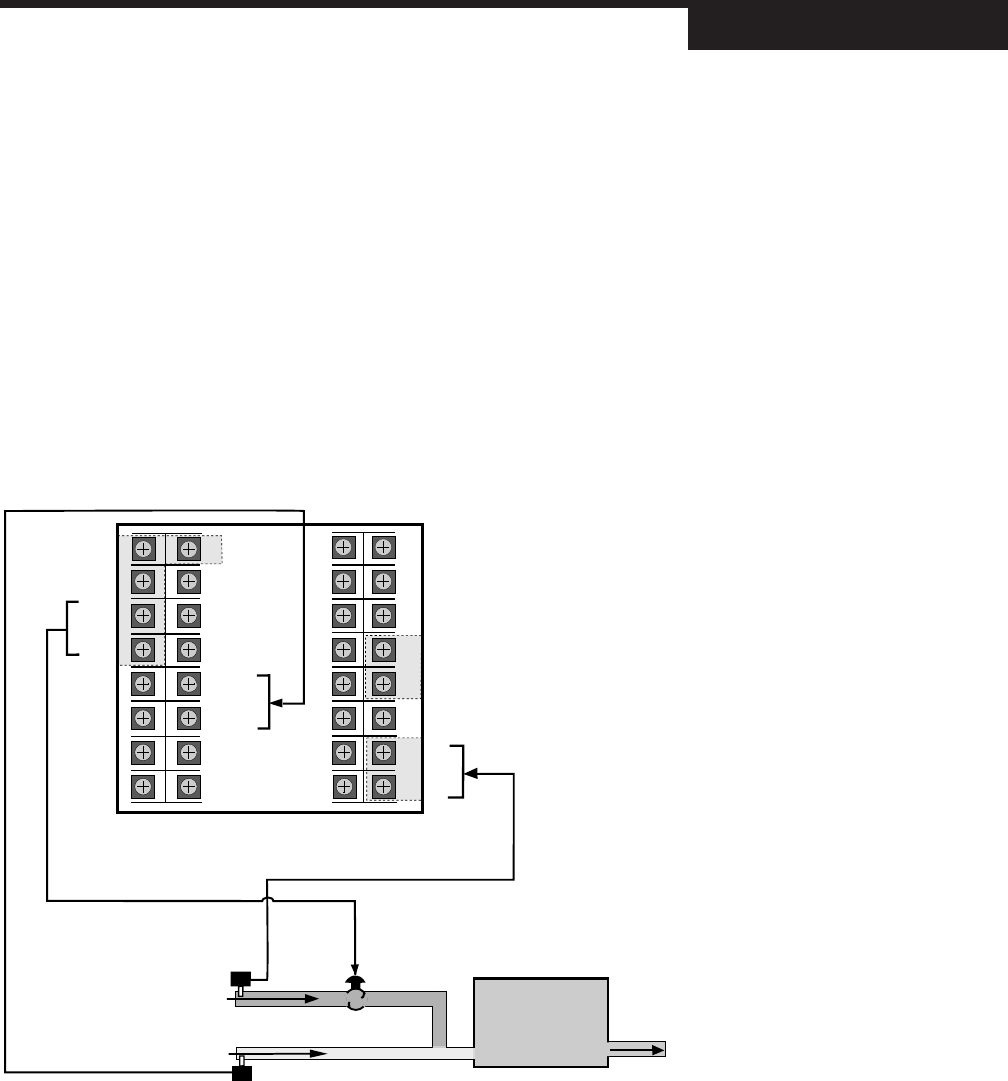

For this example, as shown in Figure 7.21, we would set RSP RATIO to 2.0. If

the flow of Material B is measured at 50 gallons/minute, the effective remote

setpoint value would be 2 times 50, or 100. The 535 controller would try to

maintain the flow of Material A at 100. As the flow of Material B changes, the

setpoint would change accordingly, always in a 2:1 ratio.

Hardware Configuration

• Set the process variable jumper and remote setpoint jumper to mA. Make

sure that both inputs are set up to accept the corresponding signal from the

flow transmitters.

• Wire as in Figure 7.21.

Software Configuration

1. Make sure that the range of both inputs matches the range of the

corresponding transmitter:

1

2

3

4

5

6

7

816

15

14

13

12

11

10

9

17

18

19

20

21

22

23

24

32

31

30

29

28

27

26

25

BOTTOM

(As viewed from rear)

EARTH GND

PV 1+

PV 1–

AC+

AC–

OUT 1–

OUT 1+

MIXER

CONTROLLED STREAM

RSP+

RSP–

flow

sensor

WILD STREAM

MATERIAL B

MATERIAL A

flow

sensor

Figure 7.21

Ratio Control in Mixing Applicatoin