User`s manual

Table Of Contents

- 535 User's Manual

- Table of Contents

- Chapter 1: Introduction

- Chapter 2: Basic Interface

- Chapter 3: Installation

- Chapter 4: Hardware Set Up

- Chapter 5: Software Configuration

- Chapter 6: Tuning

- Chapter 7: Applications

- Control Type

- Alarms

- Duplex Control

- Slidewire Position Proportioning Control

- Velocity Position Proportioning Control

- Staged Outputs

- Retransmission

- Digital Inputs

- Remote Setpoint

- Multiple Setpoints

- Multiple Sets of PID Values

- POWERBACK

- Self Tune–POWERTUNE®

- Ramp-To-Setpoint

- Input Linearization

- Load Line

- Security

- Reset Inhibition

- Process Variable Reading Correction

- Serial Communications

- Cascade Control

- Ratio Control

- Appendix 1: Menu Flowcharts

- Appendix 2: Parts List

- Appendix 3: Troubleshooting

- Appendix 4: Calibration

- Appendix 5: Specifications

- Appendix 6: Glossary

- Appendix 7: Isolation Block Diagram

- Return Procedures and Warranty Information

- 500 Series Process Controllers User's Manual

100 Chapter 7 535 User's Manual

Applications

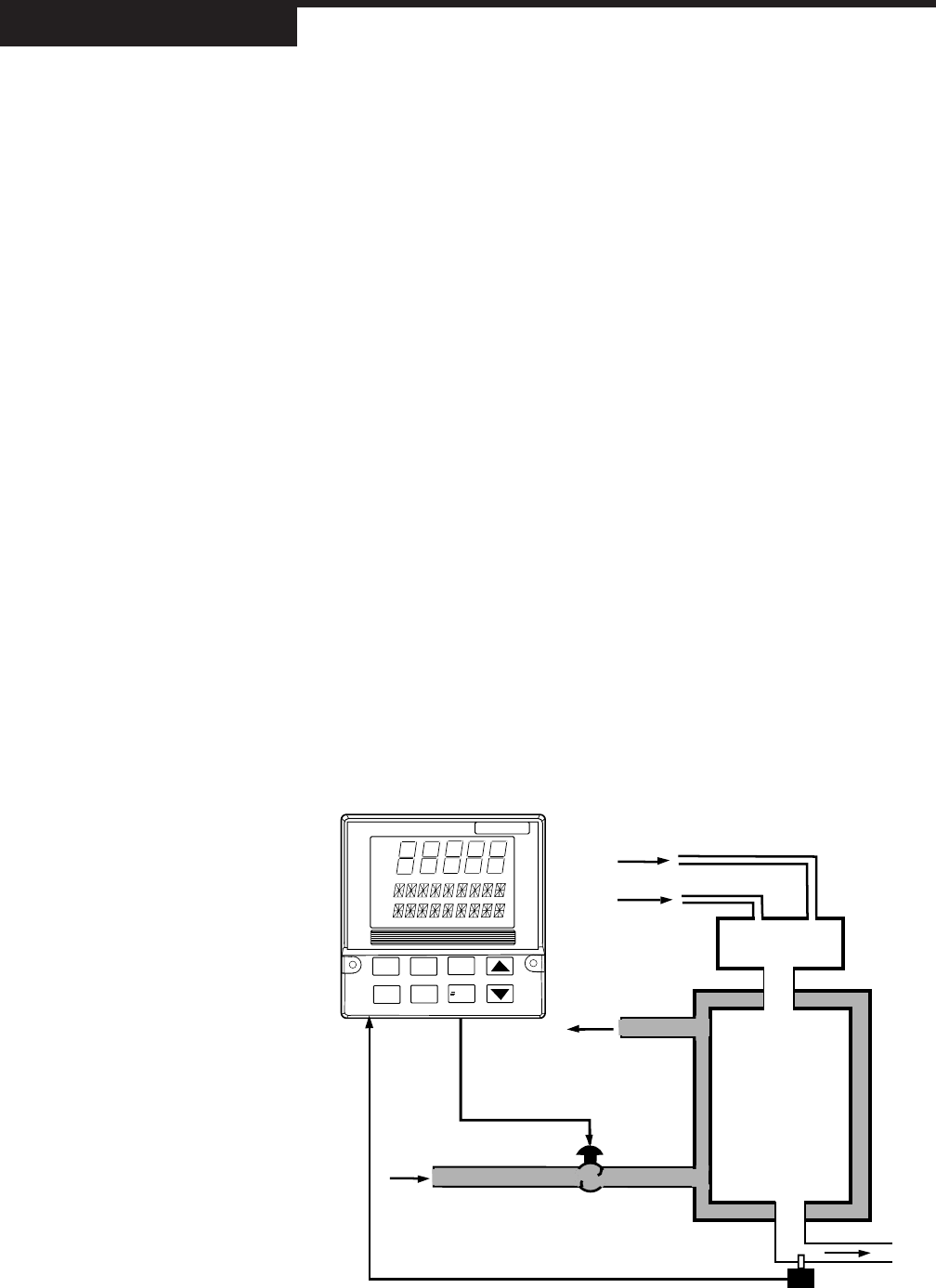

Figure 7.19

Heat Exchanger Control Loop for

Steam Supply

raw

materials

MIXER

temperature sensor

steam

HEAT

EXCHANGER

MANUAL

DISPLAY

SET PT

FAST

MENU

ACK

535

OUT

1 2

ALM

1 2

DESIG. SP to the desired setpoint.

U. CASCADE CONTROL

While a single 535 Controller is effective in maintaining many control systems,

others require more sophisticated control schemes. Figure 7.19, shows a

sample control set up with a 535 controller. Cascade control is often used to

control a process more precisely. In cascade control, a second variable is

monitored in addition to the primary controlled variable. This second variable

is one that more quickly reflects any changes in the process environment.

Cascade control involves installing one feedback loop within another, as in

Figure 7.20. This second loop, based on steam pressure, is called the inner or

secondary feedback loop. The outer or primary feedback loop is based on the

temperature of the liquid in the heat exchanger. However, instead of directly

positioning the steam valve, the output of the primary 535 controller is now used

to adjust the setpoint of the secondary 535 controller, which then positions the

valve.

Cascade Control is typically used for the following:

• A slow responding process with a significant lag time

• A process requiring more advanced or tighter control

• A process where two PID control loops need to interact to achieve optimum

control. Cascade control is commonly implemented in temperature control

applications where the main control variable is affected by another

variable, i.e., pressure.

Example

In Figure 7.19 we have a 535 set up to control a heat exchanger. In a PID-

equipped heat exchanger, pressure in the steam shell more quickly reflects

fluctuations in the steam supply than does the process liquid’s temperature.