Manual

www.climacoolcorp.com

42

Chiller Operation and Maintenance

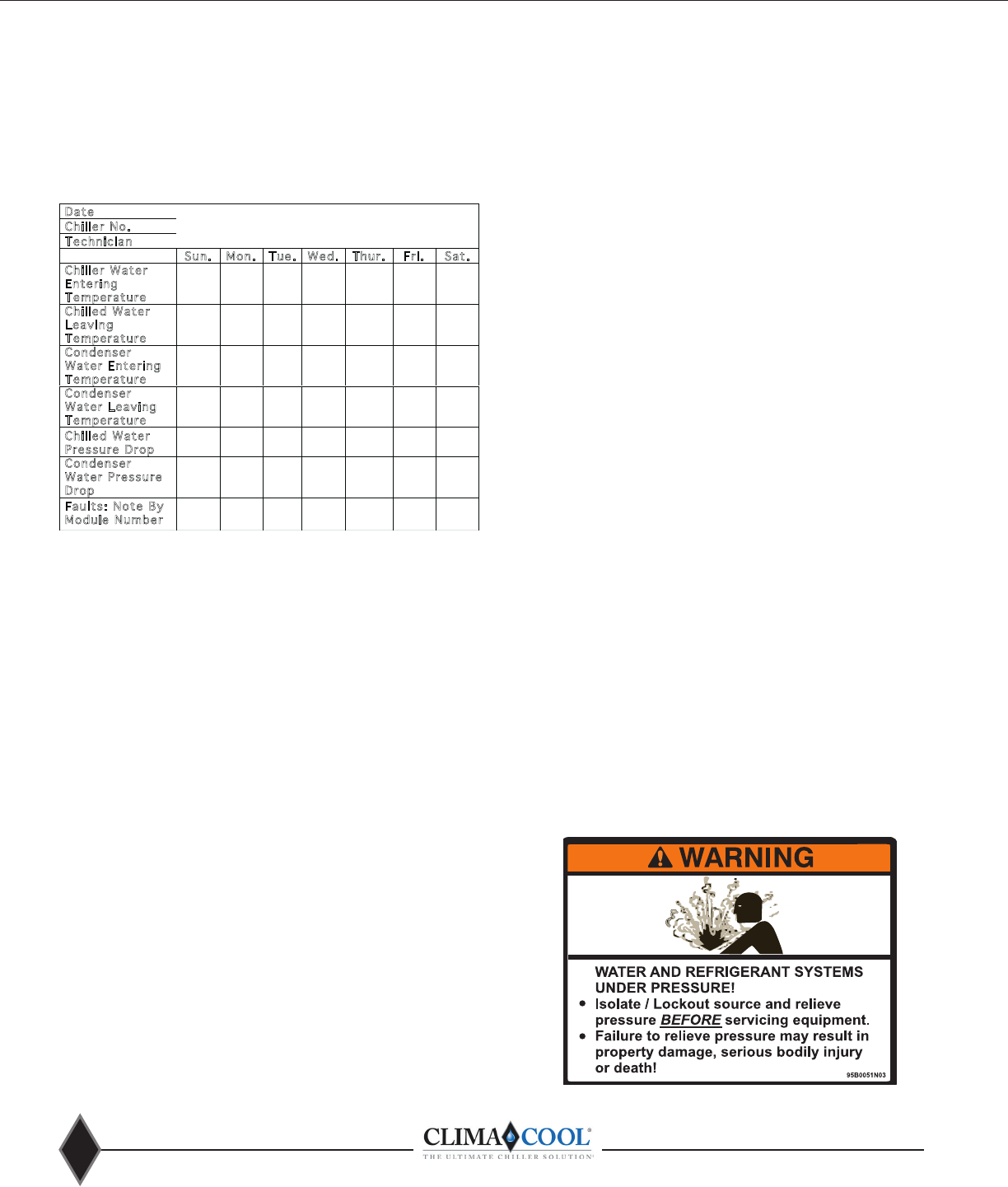

Pressure and Temperature Log

A log of temperatures and pressures should be taken

regularly. Periodically conduct a visual inspection of the

chiller to identify problems before they reach the point of

failure. As with any mechanical system, it is necessary to

of the chiller.

Maintaining a Daily Log

Date

Chiller No.

Technician

Sun. Mon. Tue. Wed. Thur. Fri. Sat.

Chiller Water

E

ntering

T

emperature

Chilled Water

L

eaving

T

emperature

Condenser

W

ater Entering

T

emperature

Condenser

W

ater Leaving

T

emperature

Chilled Water

P

ressure Drop

Condenser

W

ater Pressure

D

rop

Faults: Note By

M

odule Number

Daily

• A daily operational log should be kept.

• Perform visual inspection.

• Record entering and leaving chiller water and

condenser water temperatures and pressures.

• Properly document all data taken.

• Note any problems that may exist and

immediately plan for further investigation. If

repair is necessary, schedule for the earliest

possible date.

Weekly

• Review daily log from previous week.

• Perform visual inspection.

• Properly document all data taken.

• Note any problems that may exist and immediately

plan for further investigation. If repair is necessary,

schedule for the earliest possible date.

Quarterly

• Check Master Control Panel operating parameters

and set points.

• Check temperature drop/rise on each individual

heat exchanger. *

• Check compressor oil level.

• Check compressor oil color.

evaporator and condenser heat exchangers.

• Properly document all data taken.

• Check all electrical connections for tightness.

compressors) heat exchanger is generally 10°F. If only one

compressor is running, the temperature drop/rise will be

approximately 5°F. Some projects are designed to have a

higher or lower temperature drop on either the evaporator

or the condenser depending on application. Consult the

these values. If the temperature drop/rise is greater than the

the strainer may need to be cleaned.

Annual

43 – Chemical Clean In Place Washing).

• Remove and clean all waterside strainers.

• Manually operate all waterside isolation valves,

if provided, on each module.

• Check all electrical connections for tightness.

• Perform leak check on all refrigerant circuits.

• Check all header piping couplings for tightness.

• Check oil level and color on each compressor.

• Check and test all refrigerant safeties for

proper operation.

• Check all peripheral systems for proper operation.

• Check and test CoolLogic Control System.

• Verify set points, sensors and general control

• Properly document all data taken.