Operating instructions

Kettle Safety Inspection Checklist

SE90047

Just recently a competitor’s steam jacketed kettle exploded causing serious

personal injury and damage to a kitchen. In most cases these accidents are caused by

poor maintenance and/or incorrect installation.

We at Cleveland would like to restate that regular inspection and maintenance of units is essential to

obtain trouble free and safe operation of equipment. Inspections must include testing of the pressure relief

valve and checks of the operating system to insure that it has not been altered.

No safety features designed into the equipment should ever be tampered with

. Tampering

with or bypassing controls is a very dangerous practice and unfortunately we have seen several cases of this.

Following is a short list of the most common and the most dangerous alterations performed on kettles.

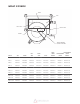

✘

Plug

✘

Tube

diameter

reduced

✘

Frozen,

stuck, or

plugged

✘

Plumbed to

drain or

water line

1

2

3

4

✔

✔

✔

Incorrect Installations

1

Safety valve has plug threaded into the discharge opening

preventing any steam from escaping.

2

Safety valve’s tube diameter has been reduced.

3

Safety valve is sticking, frozen shut or plugged. To test, refer to Service

Bulletin SE90038 rev. 2, “Pressure Relief Valve Periodic Testing”.

4

Safety valve is plumbed to a drain or water line creating back

pressure and reducing flow.

SAFETY VALVE:

The above illustrations show the three variations

of factory installed Safety Valves.

Any modifications are unacceptable.

✔