Manual

– 3 –

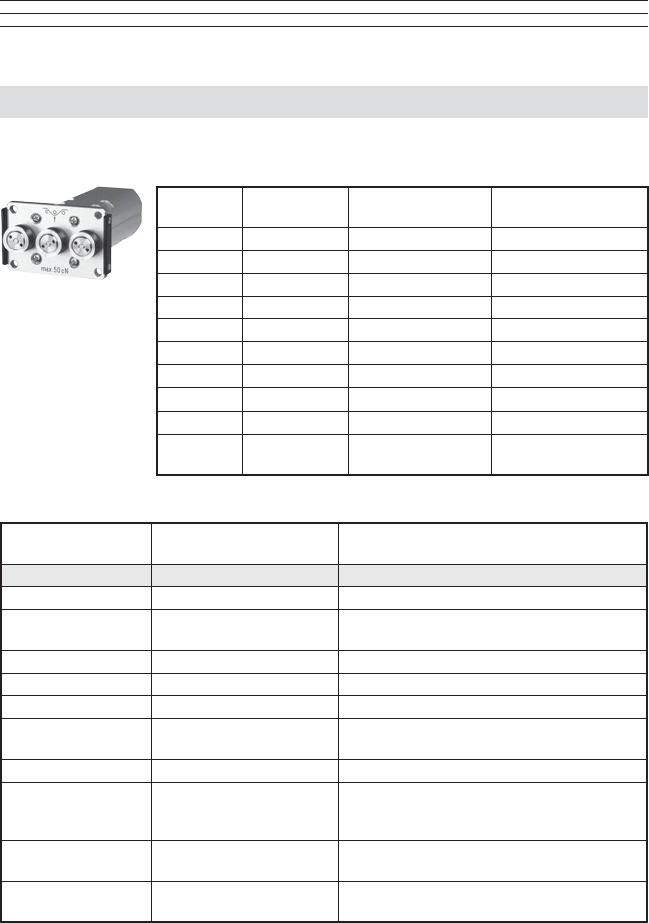

2.0 AVAILABLE MODELS

2.1 TS2 Models

Model Tension

Ranges [g]

*Measuring Head

Width [mm]

**Factory

Calibration Material

TS2-50 0 - 50 64 PA: 0.12 mm Ø

TS2-100 0 - 100 64 PA: 0.12 mm Ø

TS2-200 0 - 200 64 PA: 0.12 mm Ø

TS2-500 0 - 500 64 PA: 0.20 mm Ø

TS2-1K 0 - 1000 64 PA: 0.30 mm Ø

TS2-2K 0 - 2000 124 PA: 0.50 mm Ø

TS2-5K 0 - 5000 124 PA: 0.80 mm Ø

TS2-10K 0 - 10 Kg 124 PA: 1.00 mm Ø

TS2-20K 0 - 20 Kg 224 PA: 1.50 mm Ø

TS2-50K 0 - 50 Kg 224

Steel rope: 1.5mm Ø

(7 x 7 x 0.20)

TS2 Guide Rollers

V-Groove

Line Speed

[m/min ... max.]

Roller Material

Standard 2000 Hardcoated aluminium

Code K 3500 Hardcoated aluminium

Code H 5000

Plasma-coated aluminium

(TS2-100 and higher ranges)

Code T 1000 Plastic (POM) black

Code W 1000 Nickel-plated steel

Code ST 1000 Hardened steel

Code B 1000

Tempered steel, specially for

measuring tire cord

Code CE1 1000 Ceramic

Asymmetrical

Groove

Code ASY

1000

Hardcoated aluminium

(TS2-500 and higher ranges)

Code ASYB 1000

Tempered Steel

(TS2-500 and higher ranges)

U-Groove

Code U

2000

Hardcoated aluminium

(TS2-500 and higher ranges)

* Depending on model, either width of lament guide or outer distance between outside

guide rollers.

** Suitable for 95% of applications. PA = Polyamide Monolament

Should the process material differ signicant from the factory calibration material

in size, rigidity or shape, we recommend special calibration using customer supplied

material.

International unit of tensile force: 1 g = 1.02 g = 0.01 N

1 Kg = 1.02 kg = 10.00 N