Operating Guide

56

dump body is supported by the body prop.

1. Park the trailer on a rm and level surface.

2. Pump grease into the dump body hinge ttings and

rear door hinges every month.

3. Raise the dump body and place the body prop in

the upright position. Lower the dump body onto

the body prop. The body prop must engage the

receiver.

4. Pump grease into the ttings on each end of

the cylinder(s) and in the scissor mechanism (if

equipped). The number of grease ttings and

location on the scissor mechanism will vary by

trailer model.

5. For trailers equipped with fold down sides, pump

grease into each tting on the fold down side hinges

every month.

9.2.11 hydraulIc reSerVoIr

Check uid level prior to towing the trailer. The reservoir

is normally located inside the battery box.

The dump body must be fully lowered before checking

uid level. The reservoir should be lled to the full mark

on the side of the reservoir.

Use a quality hydraulic uid with anti-wear properties,

rust and oxidation inhibitors. Fluid ejecting from the

reservoir could indicate a low battery.

9.2.12 lug nutS or BoltS

Lug nuts or bolts are prone to loosen right after a wheel

is mounted to a hub. When driving on a remounted

wheel, check to see if the lug nuts or bolts are tight

after the rst 10, 25 and 50 miles of driving, and before

each tow thereafter.

^ WARNING

Lug nuts or bolts are prone to loosen after

being rst assembled. Death or serious

injury can result.

Check lug nuts or bolts for tightness on a

new trailer, and after re-mounting a wheel

at 10, 25 and 50 miles.

^ WARNING

Metal creep between the wheel rim and lug

nuts or bolts can cause rim to loosen.

Death or injury can occur if wheel comes

off.

Tighten lug nuts or bolts before each tow.

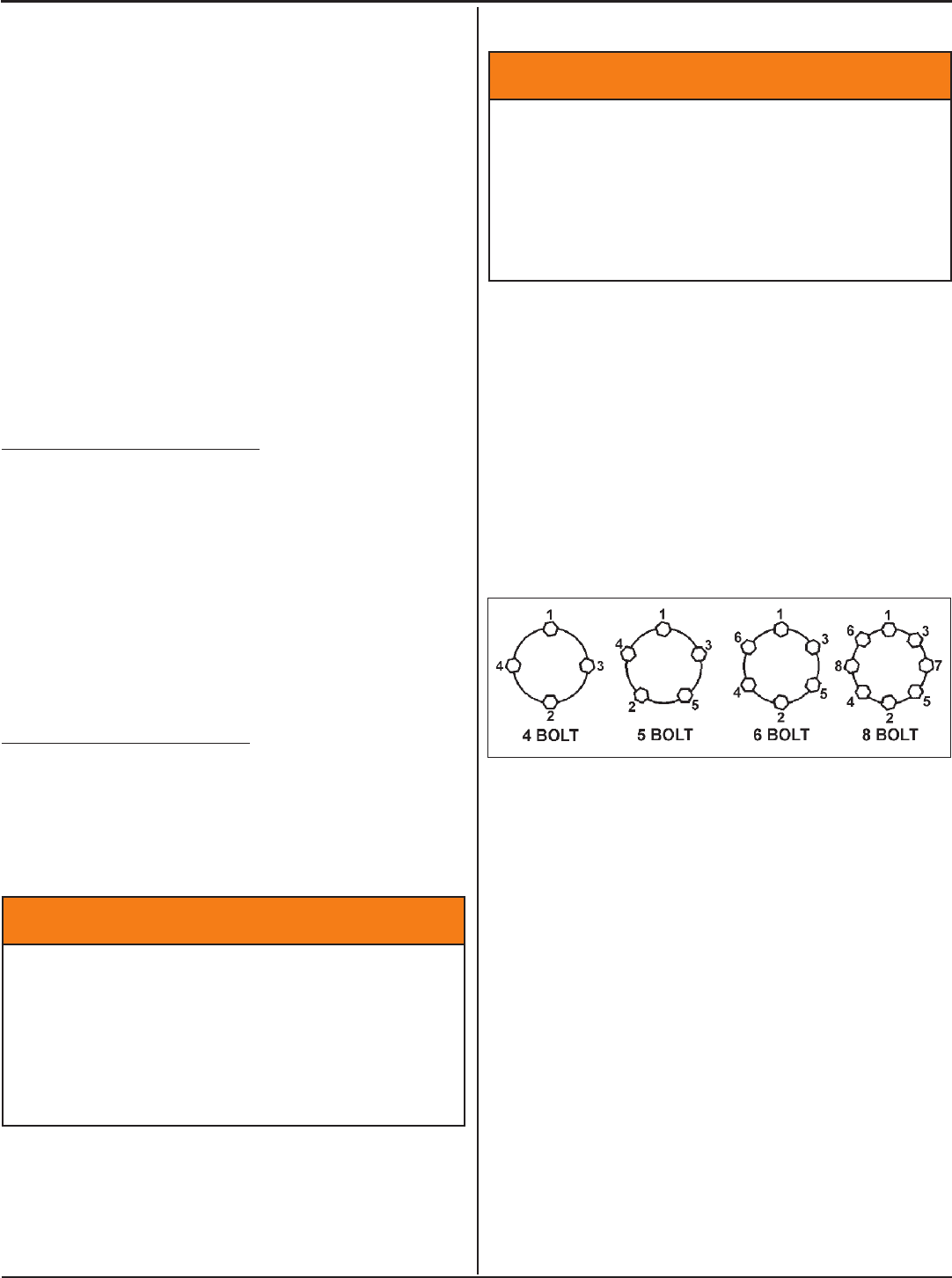

Tighten the lug nuts or bolts in three stages to the

nal torque for the axle size on your trailer, to prevent

wheels from coming loose. Tighten each lug nut or bolt

in the order shown in the following gure.

Use a calibrated torque wrench to tighten the fasteners.

Verify that wheel studs are free of contaminates such

as paint or grease, which may result in inaccurate

torque readings. Over-tightening will result in breaking

the studs or permanently deforming the mounting stud

holes in the wheels, and will void the axle warranty.

See your axle manufacturers manual or your dealer for

wheel nut or bolt torque specications.

If your ball mount is welded to the shank, adjusting the

ball height and angle can be rather difcult. This is why

using a ‘L’ shaped drop bar shank with holes about

every two inches is handy. The ball is mounted on a

bracket that is bolted to the drop bar and its height is

easily adjusted. The ball angle can also be adjusted

with a spacer on the top of the ball mount between it

and the drop bar and an adjusting nut at the bottom to

hold the mount steady.

Inspection, Service And Maintenance