Operating Guide

48

Check uid level prior to using the trailer. The master

cylinder is normally located on the tongue of the

trailer. The uid level must maintained at full mark on

reservoir. Check with your dealer for the type of brake

uid used in the brake system.

9.2.3.2 hydraulIc Surge Brake

Before each tow, perform the following steps:

1. Check that the brake master cylinder level as

instructed above. Check for leaks and repair as

required.

2. Examine the actuator for wear, bent parts, corroded/

seized parts, or other damage. Have the affected

components replaced with genuine service parts.

3. Check to determine that the actuator mounting bolts

are tightened to the manufacturer’s specication.

4. Test the actuator and brake function as described

in the Coupling To Tow Vehicle section of this

manual. Actuator travel over one inch indicates

that the brakes need adjustment (or that the

actuator has been structurally damaged). Actuator

travel is the distance the coupler case assembly

moves to the outer case during braking. Adjust the

brakes following the instructions given in the brake

installation manual. Failure to adjust brakes will

result in loss of braking.

5. Before storage or after extended use, apply motor

oil to the coupler components and the internal

rollers to keep them moving freely and to prevent

corrosion.

6. See the surge brake manufacturer’s manual for

other inspection and maintenance activities. If you

do not have this manual, contact your dealer for

assistance.

9.2.3.3 maSter cylInder BleedIng

Remove the master cylinder’s cap and ll the reservoir

to three quarters full with DOT-3 or DOT 4 brake uid.

DO NOT allow brake uid to contact painted surfaces

since it will damage the nish. Wipe up any spills

immediately and wash the area with water.

Bleed the brake system manually or with a pressure

bleeder. Pressure bleeding equipment simplies the

process, and is available at most automotive supply

stores. Use the instructions provided with the pressure

bleeder. If you chose to manually bleed the system,

an assistant is required. Use the following steps to

manually bleed the brake system:

1. Disconnect the trailer from the tow vehicle and jack

the trailer’s tongue until it is horizontal. Make sure

that the wheels are blocked so that the trailer will

not roll away.

2. Fill the master cylinder with correct uid.

3. Install a bleeder hose on the bleeder screw of the

farthest wheel cylinder from the actuator. If the

trailer has multiple axles, bleed the rear axle rst.

Submerse the other end of the hose in a glass

container of brake uid, so that air bubbles can be

observed.

4. Open the bleeder screw and have an assistant

stroke (but not release) the actuator. Brake uid

and/or air bubbles will ow into the jar. Close the

bleeder screw. The helper can then allow the

actuator to return to its rest position.

5. Repeat the process until no more bubbles are

released with the stroke. Air trapped in the brake

lines will greatly reduce your braking efciency. Be

sure to close the bleeder screw securely when the

cylinder is fully bled. Repeat the bleeding operation

at each wheel cylinder. During the bleeding process,

replenish the master cylinder reservoir with fresh

brake uid so that the level does not fall below half

full. This will ensure that no air is drawn into the

system.

6. After all brakes have been bled, rell the master

cylinder before operating. Be sure to install the

master cylinder ller cap.

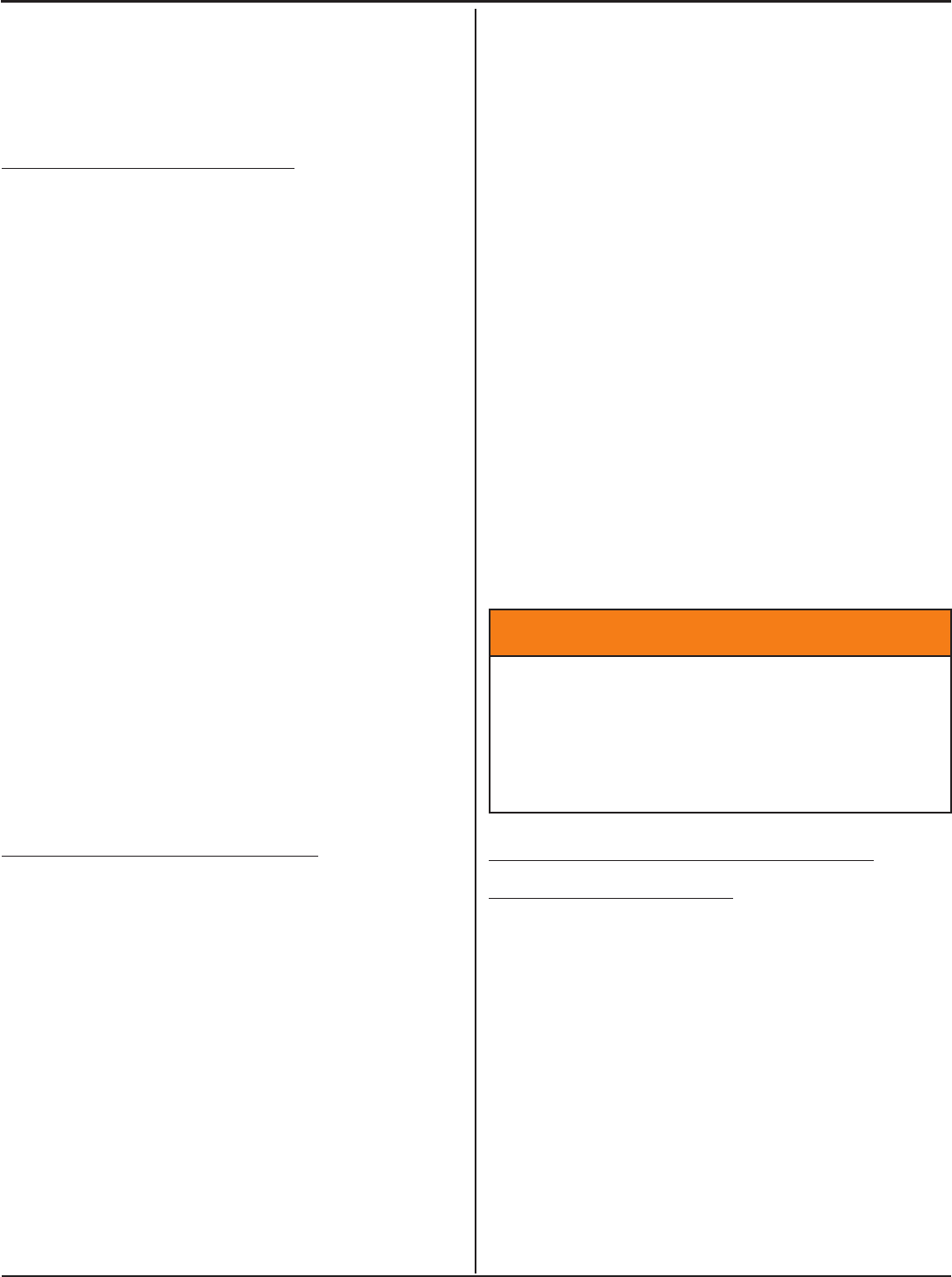

^ WARNING

Use only fresh brake uid from a sealed

container. DO NOT reuse uid. After lling

and bleeding, rell the actuator.

Failure to maintain an adequate uid level

may cause brake failure.

9.2.4 traIler connectIon to tow VehIcle

9.2.4.1 coupler and Ball

Before each tow, coat the ball with a thin layer of

automotive bearing grease to reduce wear and ensure

proper operation; and check the locking device that

secures the coupler to the ball for proper operation.

See the coupler manufacturer’s manual for other

inspection and maintenance procedures. If you do not

have this manual, contact your dealer for assistance.

If you see or feel evidence of wear, such as at spots,

deformations, pitting or corrosion, on the ball or coupler,

immediately have your dealer inspect them to determine

the proper action to prevent possible failure of the ball

and coupler system. All bent or broken coupler parts

must be replaced before towing the trailer.

Inspection, Service And Maintenance