Operating Guide

33

board should be 4 feet or longer so it will extend several

feet above the actuator. Keep the end of the board

a few inches off the ground, and position it to press

against the front end of the actuator’s coupler. Press

the board towards the rear of the trailer.

Keep pressing the top of the board to stroke the

actuator and its internal master cylinder. If the trailer

brake system is operational, the brakes will apply and

keep the trailer from rolling away from you. Properly

adjusted uni-servo or duo-servo type brakes will

prevent you from moving the trailer back more than

a few inches. Free-backing type brakes will initially

provide rolling resistance, but continued force on the

board will switch them into free-backing mode, and

you’ll be able to move the trailer backwards.

If you have uni-servo or duo-servo brakes, and stroking

the actuator (as described above) causes the trailer to

roll away from you freely or with only minimal resistance,

the brakes are NOT applying properly. If you have free-

backing brakes and stroking the actuator (as described

above) causes the trailer to roll away without initial

resistance, then the brakes are NOT applying properly.

The brake system MUST be evaluated to determine

the cause of the problem and corrective action MUST

be taken before the trailer is used. Use this procedure

each time you tow your trailer to check your surge

brake system operation.

4.3.5.4 teSt Surge Breakaway SyStem

Before towing, check that the breakaway lever and

lanyard are properly positioned. If the breakaway lever

and lanyard are not located correctly due to either the

lanyard being pulled during use or by accident, it MUST

be reset prior to the trailer being moved.

See the Surge Brake Actuator manual for the correct

resetting and testing procedure.

^ WARNING

The breakaway system is designed to

operate if the trailer separates from the tow

vehicle.

DO NOT use the breakaway system as a

parking brake.

4.4 uncouple traIler

Follow these steps to uncouple trailer from the tow

vehicle:

1. Park the trailer on a rm level surface and block

trailer tires.

2. Disconnect electrical connector.

3. Disconnect breakaway brake switch lanyard.

4. Disconnect safety chains from tow vehicle.

5. Unlock the coupler and open it.

6. Before extending jack, make certain the ground

surface below the jack pad will support the tongue

load.

7. Rotate jack handle to extend the jack and transfer

the weight of the trailer tongue to the jack.

8. Raise the trailer coupler above the tow vehicle

hitch.

9. Drive tow vehicle forward.

4.5 tongue weIght

It is critical to have a portion of the trailer load carried

by the tow vehicle. That is, the trailer tongue must exert

a downward force on the hitch. This is necessary for

two reasons. First, the proper amount of tongue weight

is necessary for the tow vehicle to be able to maintain

control of the tow vehicle/trailer system. If, for example,

the tongue exerts an upward pull on the hitch, instead

of pushing down on it (because the trailer is overloaded

behind its axle(s)), the rear wheel of the tow vehicle

can lose traction or grip and cause loss of control. Also,

even if there is some weight on the tongue, but not

enough weight on the tongue, the trailer can become

unstable at high speeds. Remember, the faster you go

the more likely the trailer is to sway.

If there is too much tongue weight, the tow vehicle is

prone to jack-knife. The front wheels of the tow vehicle

can be too lightly loaded and cause loss of steering

control and traction, if the front wheels are driving.

In addition to tow vehicle control, tongue weight

is necessary to insure that the trailer axle(s) do not

exceed their Gross Axle Weight Rating (GAWR).

In the following table, the second column shows the

rule of thumb percentage of total weight of the trailer

plus its cargo (Gross Trailer Weight, or “GTW”) that

should appear on the tongue of the trailer. For example,

a large trailer with a loaded weight of 6,000 pounds,

should have 10-15% of 6,000 pounds (600-900 lbs.)

on the hitch.

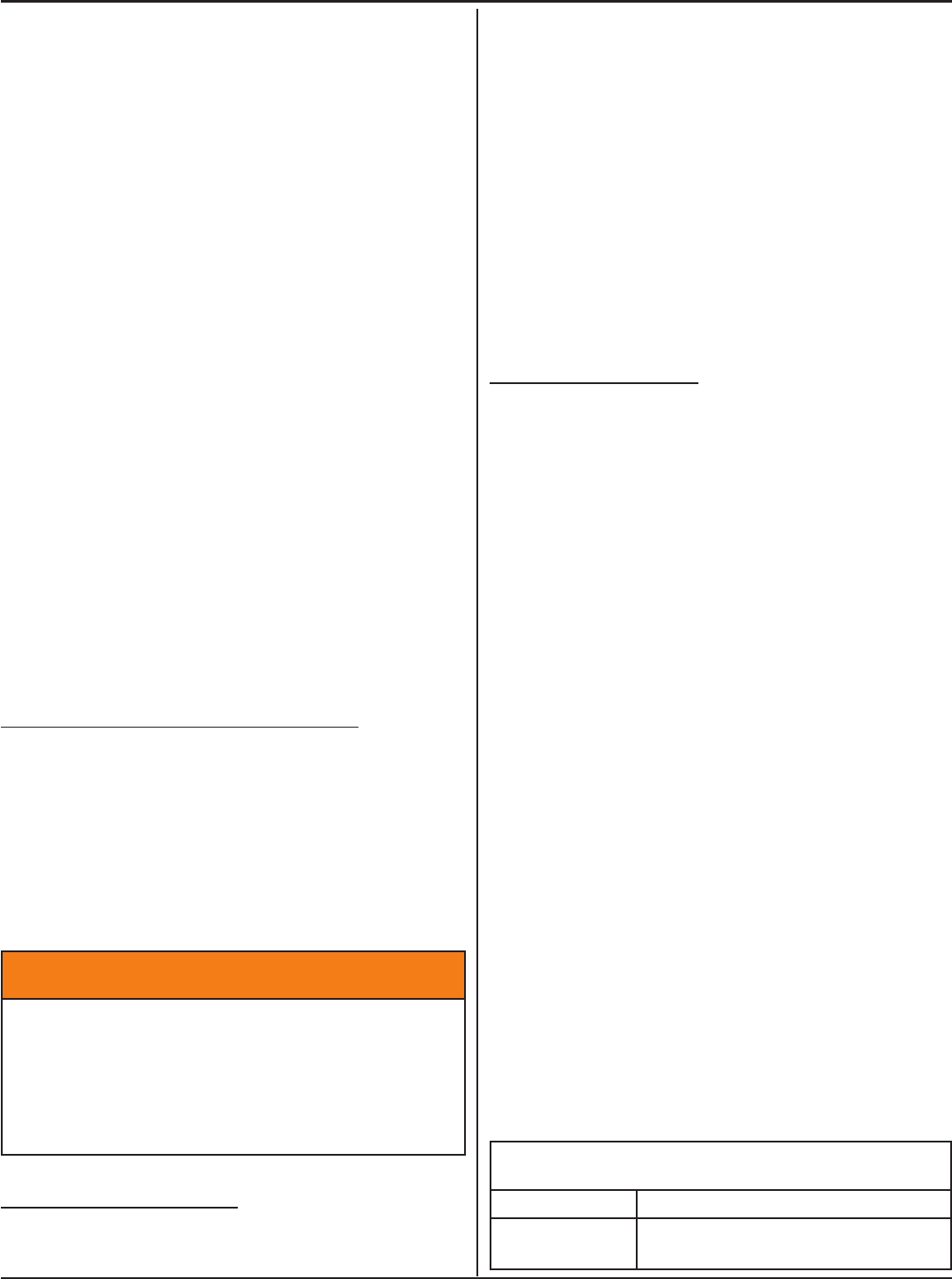

Tongue Weight as a Percentage of Loaded Trailer

Weight

Type of Hitch Percentage

Ball Hitch or

Ring & Pintle

10-15% for large trailers

6-10% for small trailers

Coupling To Tow Vehicle