Owner's manual

Table Of Contents

- Revision and Copyright Information

- Limited Warranty

- Assistance

- Table of Contents

- 1. Preparation and Siting

- 2. Hardware Installation

- 2.1 Base Foundation

- 2.2 Tower/Pole

- 2.3 Enclosure

- 2.4 Crossarm and Sensor Installation

- 2.5 Communication Peripherals

- 2.6 Lightning Rod Installation

- 2.7 Solar Panel Installation

- 2.8 Battery Installation

- 2.9 Restraining Cables and Sealing/Desiccating Enclosure

- 3. ET Software

- 4. Maintenance, Troubleshooting, and Schematics

- 4.1 Maintenance

- 4.2 Troubleshooting

- 4.2.1 No Response Using the CR1000KD Keypad

- 4.2.2 No Response from Datalogger through SC32B, RAD Modem, or Phone Modem

- 4.2.3 NAN or (INF Displayed in a Variable

- 4.2.4 Unreasonable Results Displayed in a Variable

- 4.2.5 NAN or (INF Stored in a Data Table

- 4.2.6 Communication Problems when using an RF450 Radio

- 4.2.7 Gill WindSonic1-ET Diagnostic Diagnostic Codes

- 4.3 Schematics of Connectors

- Appendix A. T107 Maintenance Log

- Appendix B. PS24 24 Ahr Power Supply and 10 x 12 inch Enclosure

- Appendix C. Exploded Views

- Appendix D. Default Programs

- Appendix E. Step-down Transformer Installation

- Campbell Scientific Companies

T107 Weather Station

filter in the cup of water. Remove the filter and allow to air dry before

putting it back on the end of the sensor.

6 months

• Replace 034B-ET’s anemometer bearings and reed switch if operating

under harsh conditions, such as constant high winds, blowing dust, and/or

salt spray contamination.

1 year

• Replace 034B-ET wind speed (anemometer) bearings (pn 3648). Contact

your local Toro distributor for service.

• Replace 034B-ET wind speed (anemometer) reed switch (pn 13764) if

needed. Contact your local Toro distributor for service.

• Check calibration of the HMP60-ETS temp/RH probe. Sensor will tend to

drift up over time giving readings higher than 100%. Replace RH chip (pn

9598) if necessary (see FIGURE 4-1 and Section 4.1.4.1, Procedure for

Removing RH Chip).

T107 stations began shipping January 2014 with an updated gill

radiation shield retained with knurled thumb screws, using the

HMP60-ETS Temp/RH sensor. All information in this document

is also pertinent for the HMP50-ET, HMP60-ET, and HMP60-

ETR sensors.

• Replace desiccant in enclosure housing as needed.

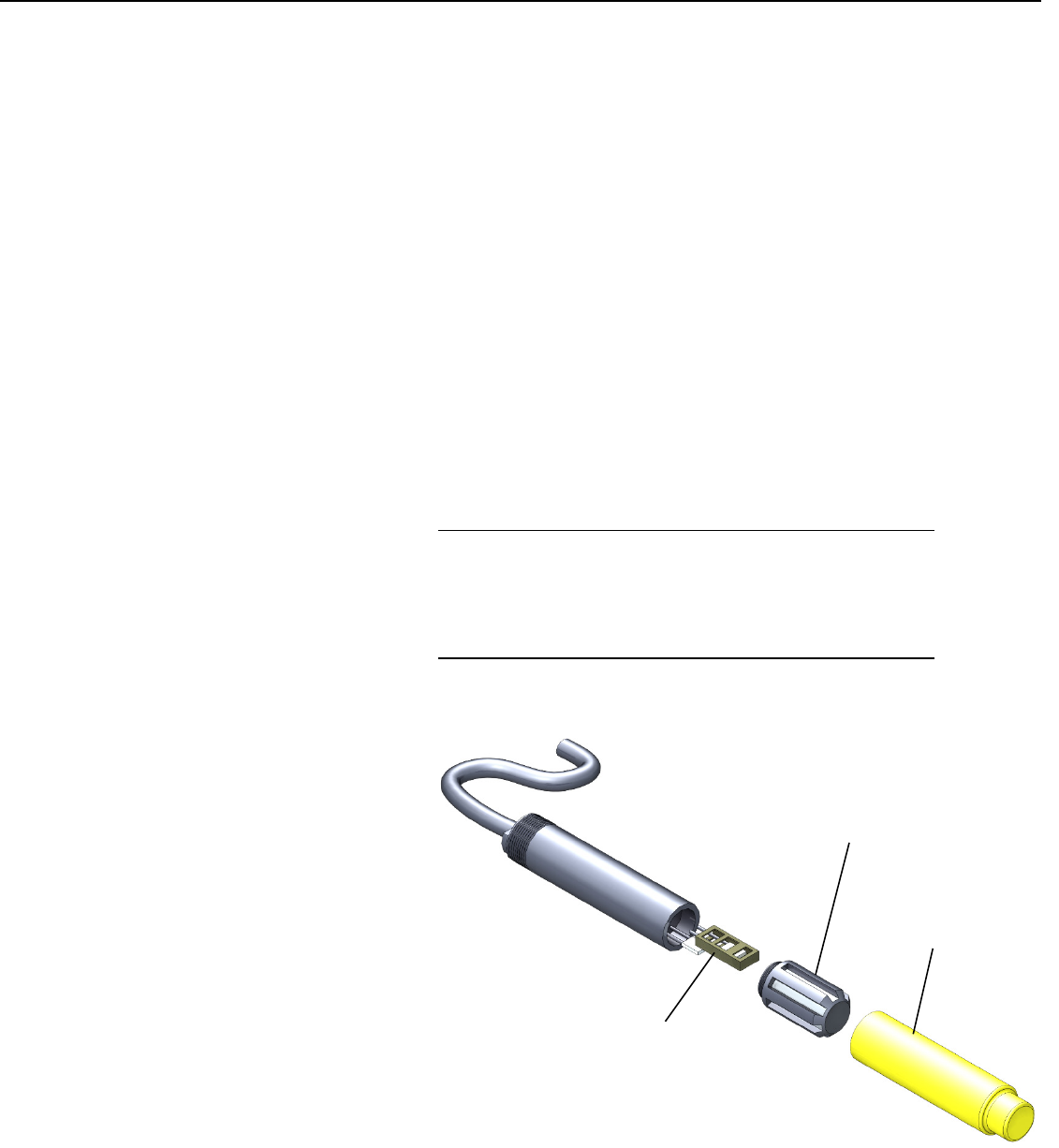

FIGURE 4-1. Exploded view of the temperature and RH sensor

(adapter not shown)

NOTE

Protective Cap

and Filter

Shipping Cap

(remove prior

to installation)

9598 RH Chip

57