Brochure

Construction details

Supply manifold

663 series

Supply manifold has manual

balancing valves for regulating flow

delivered to system circuits. The

balancing is accomplished by turning

an hex wrench into the balancing

valve in each supply outlet.

The chart on page 7 shows the

number of turns for reaching the

desired value of flow and

∆p.

668 series

The micrometric balancing valve is

made of plastic (POM) and features

an upside down V channel (1) to

provide greater precision when

regulating the flow delivered to the

system circuits.

This solution offers the following

advantages with respect to the

traditional conically shaped valve:

- greater precision, particularly for

the low flow rates usually

encountered in radiant system.

- proportional flow rates due to the

V channel in the fluid passage.

- the chart on page 7 shows the

micrometric graduated scale

number for setting the desired

value of flow and

∆p.

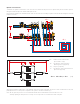

Return manifold

The return manifold is equipped

with manual shut-off valves (1)

which ar

e used to shut of

f the flow

to individual circuits.

They can also be used with a

ther

moelectric actuator which,

when used with an ambient

thermostat, maintains the ambient

temperature at the set limits when

ther

mal load varies. The stem (2)

is made of polished stainless steel

to minimise friction and prevent

harmful encrustation from forming.

The control device upper part

featur

es a double EPDM

O-ring seal (3) – (4) on the sliding

stem.

The valve (5) is made of EPDM and

is moulded to optimise the hydronic

characteristics of the valve and

reduce noise to a minimum as the

fluid passes through and as it

gradually opens and closes when

operating with a

thermo-electric actuator.

Exterior shape of the manifolds and mounting brackets

The exterior of the manifold deserves special mention because it

can be cast in any shape to meet any requirements.

In the example shown below, indentations have been created in the

manifold to correspond to the plastic pipes exiting from the upper

manifold, thus partially accommodating the pipes and reducing

their overall thickness. This does not interfere with the pressure loss

values because the sections with the indentations (a) are equal to

the sections in which the pipes are branched (b) and (c) and where

the regulating parts (micrometric regulating and shut-off valve)

obstruct the passage of the fluid.

The partial accommodation of the pipes in the indentations created

in the manifold is further enhanced by the angle of the mounting

brackets, which are slanted to create a 1” (25 mm) offset between

the upper and lower manifolds.

As shown in the figure below, this offset positions the pipes so that

they perfectly match the profile of the manifold during installation.

End fitting and automatic air vent valve

The end fitting consists of a fill/drain cock (1)

and an automatic air vent valve with a

hygr

oscopic safety cap (2). It has been

specifically designed to close the air vent valve

automatically if there is water near the vent

itself.

1

1

3

4

2

5

a

b

c

CALEFFI

CALEFFI

10

0

8

6

4

2

1” (25 mm)

CAL EFFI

CAL EFFI

CA

LEFFI

CALEFFI

10

0

8

6

4

2

10

0

8

6

4

2

10

0

8

6

4

2

10

0

8

6

4

2

10

0

8

6

4

2

10

0

8

6

4

2

10

0

8

6

4

2

10

0

8

6

4

2

10

0

8

6

4

2

10

0

8

6

4

2

10

0

8

6

4

2

10

0

8

6

4

2

10

0

8

6

4

2

10

0

8

6

4

2

2

1

CALEFFI