Submittal Sheet

COLD

HOT

MIXED

1

4

2

3

5

32

60

80

100

120

140

160

Kills bacteria instantly

Kills 90% of bacteria in 2 minutes

Kills 90% of bacteria in 2 hours

Optimum temperature

for growth of bacteria

Surviving bacteria inactive

Construction details

Anti-scale materials

The material used in the construction of the Caleffi AngleMix 520 series

thermostatic mixing valve reduces jamming caused by lime deposits.

All the working parts such as shutter, seats and slide guides are made

of a special anti-scale polymer material, with a low friction coefficient,

assuring long term performance.

Temperature setting and locking

The control knob permits temperature setting between minimum and

maximum in one turn (360°). It also has a tamper-proof system to lock

the temperature at the set value.

Thermal shut-off

In the event of accidental cold water supply failure, the shutter seals

off the hot water passage, thus preventing the delivery of mixed

temperature water. This is only guaranteed when there is a minimum

temperature difference between the inlet hot water and the mixed

temperature water delivery of 18° F. Additionally, the tight closing hot

inlet port prevents temperature creep in recirculation applications.

Check valve

In systems with thermostatic mixing valves, check valves must be

installed to prevent undesired backflow. As a convenience for easier

installations, the AngleMix 5205__AC series mixing valves are supplied

complete with a check valve in the hot and cold inlet ports.

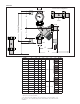

Operating principle

The thermostatic mixing valve mixes the hot and cold water at the

inlets to maintain constant mixed water at the desired set temperature.

A thermostatic sensor (1) is fully immersed in the mixed water outlet

passage (2) which, as it expands or contracts, continuously establishes

the correct proportion of hot and cold water entering the valve. The

regulation of these flows is by means of a piston (3) sliding in a cylinder

between the hot and cold water passages. This controls the passage of

hot (4) or cold (5) water at the inlet. If the inlet temperature or pressure

changes, the internal element automatically reacts to restore the set

temperature at the outlet. The AngleMix 520 series point of distribution

mixing valve is an angled configuration for easy installation to most water

heaters for direct mounting to the top pipe connections.

Thermal disinfection

The diagram shows the behavior of the bacteria Legionella Pneumophila

when the temperature conditions of the water in which it is containedvary.

In order to ensure proper thermal “disinfection”, the values must not be

below 140° F.

110

120

130

140

150

160

170

0.11 10 100 1,000 10,000 Seconds

Partial burning

To tal burning

Safety condition.

Maximum exposure time

at a given temperature

Temperature — exposure time

Legionella-scalding risk

In systems producing domestic hot water with storage, in order to

avoid the dangerous infection known as Legionella, the hot water must

be stored at a temperature of at least 140° F. At this temperature it

is certain that the growth of the bacteria causing this infection will be

totally eliminated. At this temperature, however, the water cannot be

used directly.

As shown on the diagram opposite, temperatures of more than 120° F

can cause burning very quickly. For example, at 130° F partial burning

will occurr in approximately 30 seconds, while at 140° F partial burning

will occurr in approximately 5 seconds. The time may be reduced by 50

percent or more for children and elderly people.

In view of the above, it is necessary to install a thermostatic mixing valve

which can:

- reduce the temperature at the point of use to a value lower than that

of storage and suitable for sanitary users. For safety reasons, it is

advisable to limit the mixed water temperature to 120° F when point-

of-use anti-scalding thermostatic mixing valves are not present at all

fixtures.

- maintain the temperature constant when the incoming pressure and

temperature conditions vary.