User's Manual

5.6

Fault Finding

M889-00

02/10/95 Copyright TEL

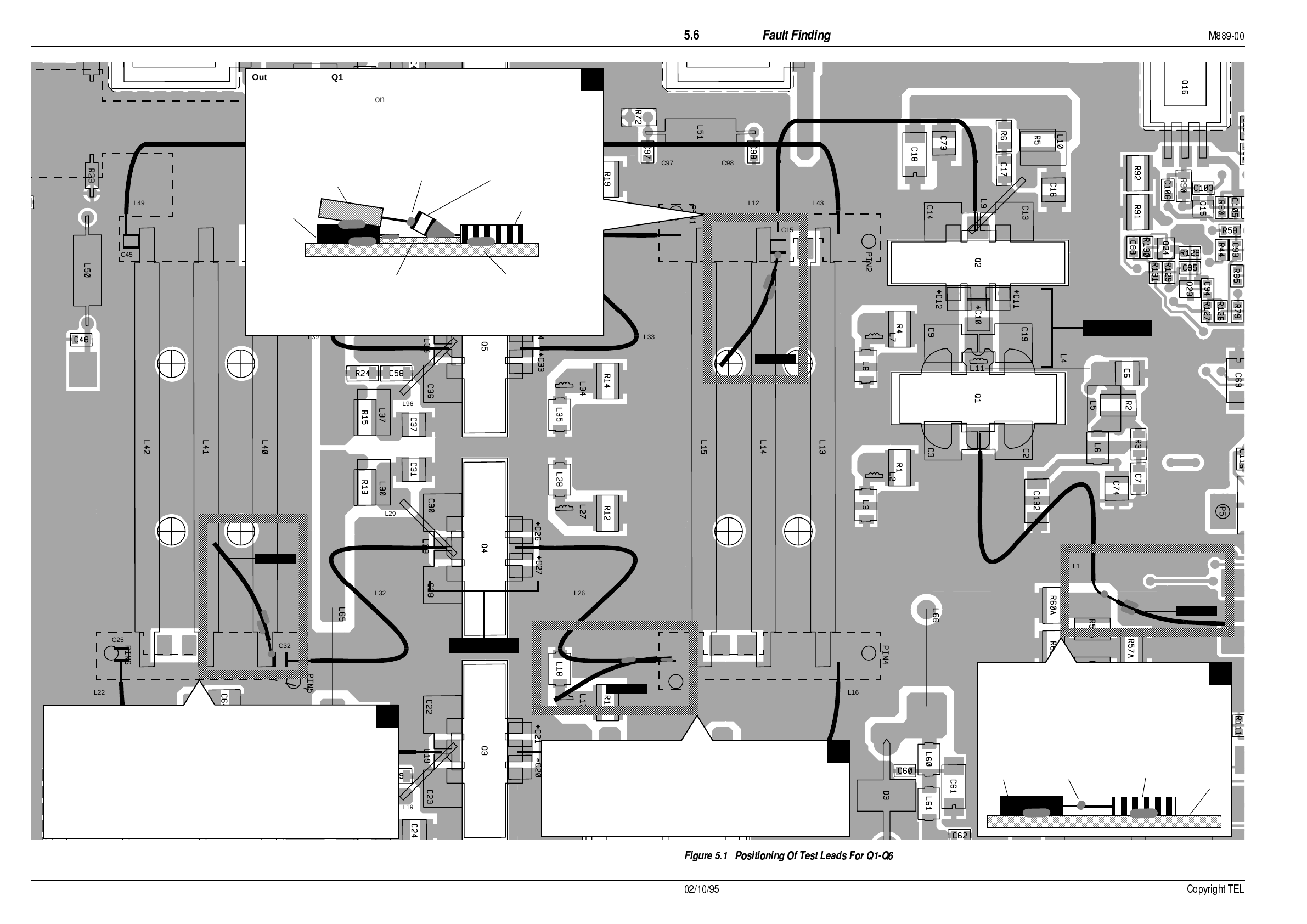

T889 PCB Layout

Bottom Side

L46

C97 C98

L19

L29

L96

C59

L22 L16

L32 L26

L1

L49 L43L12

L39 L33

C45

C38

C15

C32

C25

Output Test Lead - Q1 & Q2

1. Desolder C15 and resolder on edge as shown.

2. Remove the wireline clamping plate and solder the test lead outer core to the outer

core of the wireline (L14 shown).

3. Solder the inner core of the test lead to the raised end of C15.

4. To test Q1 & Q2, provide 2.5-3W drive power to Q1 through the input test lead. While

testing, ensure that the output test lead on Q2 is terminated at all times into a good

50

Ω

RF load.

main PCB

Teflon PCB

L14

L12

C15 (DC blocking capacitor)

output test lead

(transmission line)

(wireline)

(to wattmeter, analyser etc.)

50

Ω

test point

Input Test Lead - Q1 & Q2

1. Desolder the inner core of L1 and lift off its pad.

2. Solder the test lead outer core to the earth plane (remove

the resist first).

3. Solder the inner cores of L1 and the test lead together off

the PCB.

main PCB

L1

input test lead

50

Ω

test point

Output Test Lead - Q3-Q6 (Q4 Shown)

Refer to drawing B above.

1. Desolder the appropriate DC blocking capacitor and resolder on edge.

2. Remove the wireline clamping plate and solder the test lead outer core to the outer

core of the wireline.

3. Solder the inner core of the test lead to the raised end of the DC blocking capacitor.

4. To test, drive the transistor with approx. 10W over the range 800-870MHz and expect

a minimum output of 30W.

Input Test Lead - Q3-Q6 (Q4 Shown)

1. Desolder the appropriate transmission line inner core and lift off its pad.

2. Solder the test lead outer core to the transmission line outer core.

3. Solder the inner cores of the transmission line and test lead together off

the PCB.

not 50

Ω

not 50

Ω

test lead

test lead

test lead

test lead

A

B

C

D

Figure 5.1 Positioning Of Test Leads For Q1-Q6