Operating instructions

7

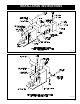

1. BOILER PIPING

Attach supply and return piping lines and insert plugs

and bushings in connections as required. Supply and

return piping headers are detailed in Figure 2.

IT IS IMPORTANT TO COMPLY WITH THE MINIMUM

PIPING REQUIREMENTS IN ORDER TO ENSURE

MAXIMUM PERFORMANCE AND RELIABILITY. ON

STEAM BOILERS, PARTICULAR ATTENTION SHOULD

BE GIVEN TO THE CONSTRUCTION OF THE SUPPLY

HEADER.

The nominal temperature differential between supply

and return water recommended for Burnham retube

water boilers is 20°F. As a precaution against thermal

shock, this differential should never exceed 40°F.

When differentials in excess of 30°F are anticipated

on rebox boilers, the return water should enter the boiler

at the top tting (normally the supply) and the supply

water should leave the boiler through the bottom tting

(normally the return). This ow pattern directs the return

water over the relatively cool third pass rather than

directly against the rear of the furnace.

The boiler should not be operated for any length of

time at a temperature setting that allows the formation of

condensation in the tubes or smokebox. This generally

dictates a minimum setting of approximately 140°F on

the low limit on systems with a 20°F system differential.

On cold start up, condensation can be expected until the

boiler warms up. If formation of condensate persists, the

low limit should be adjusted upward until condensate no

longer forms.

Water boilers and low pressure steam boilers must

have a set LFH at 120° minimum to avoid condensation.

High pressure steam should have a minimum LFH

temperature of 180°F.

2. RECOMMENDED WATER BOILER

RECIRCULATION LOOP

The following guidelines relating to system water

temperature uctuation and ow through the boiler must

be observed.

A. It is important to operate your boiler in such a

manner as to prevent temperature uctuation of

more then 40°F at any time. Rapid temperature

changes within the boiler can create stresses in the

boiler metal. These stresses can cause damage to

the boiler by loosening tubes, or in more severe

instances can crack tube sheet ligaments,

furnaces, or waterlegs.

B. If temperature differentials approach 40°F, to

help prevent temperature uctuations and insure

proper circulation through the boiler, a recirculation

loop as shown in Figure 10 should be considered.

The recirculation ow should be at least 1/2 GPM/

BHP at all times when the boiler is online

for operation.

3. TANKLESS HEATER

A. If boiler is ordered with tankless heater, connect

tankless heater piping as shown in Figure 2.

Install an automatic mixing valve at the tankless

heater outlet to avoid risk of burns or scalding due to

excessively hot water at the xtures. Adjust and maintain

the mixing valve in accordance with the manufacturer’s

instructions.

B. The following guidelines should be followed when

piping the tankless heaters:

4. FLOW REGULATION

If ow through the heater is greater than its rating, the

supply of adequate hot water may not be able to keep

up with the demand. For this reason a ow regulator

matching the heater rating should be installed in the

cold water line to the heater. The ow regulator should

preferably be located below the inlet so it's not subjected

to excess temperatures that may occur during “off”

periods when it is possible for the heat to be conducted

back through the supply line. The ow regulator also

limits the ow of supply water regardless of inlet

pressure variations in the range of 20 to 120 psi.

5. TEMPERING OF HOT WATER

Installation of an automatic mixing valve will lengthen

the delivery of the available hot water by mixing some

cold water with the hot. This prevents excessive and

possibly scalding hot water. Higher temperature hot

water is possible by piping the hot water from the heater

prior to entering the mixing valve. The mixing valve

should be “trapped” by installing it below the cold water

inlet to heater to prevent lime formation in the valve.

SECTION II — INSTALLATION INSTRUCTIONS

FIGURE 2

SCHEMATIC TANKLESS HEATER PIPING

CAUTION

WARNING

WARNING