INSTALLATION AND OPERATING INSTRUCTIONS FOR BURNHAM COMMERCIAL FIRETUBE BOILERS Commercial Boilers For service and repairs to the heating plant, call your local representatives. When seeking information on the boiler, provide series and size designation shown on rating plate. Boiler Number __________________ Type Firing________________ Type System _________ Project______________________________________________________________ Address_________________________________________________ Phone No.

IMPORTANT INFORMATION Burner/boiler system, as used throughout this manual, shall mean all mechanical and/or electrical equipment including the boiler, burner, pumps, compressors, feed water systems and all associated piping, electrical and control systems used and maintained in the boiler room. The following defined terms are used throughout this manual to bring attention to the presence of hazards or various risk levels or to note important information concerning the operating life of the product.

5. Keep boiler area clear and free from combustible materials, gasoline and other flammable vapors and liquids. 6. Provide positive assurance that adequate combustion and ventilation air is provided from the outdoors to the burner/boiler system and boiler room. 7. Do not place any obstructions in the boiler room that will hinder the flow of combustion and ventilating air. 8.

TABLE OF CONTENTS SECTION I General information Introduction....................................................................................................................................... 6 Setting the Unit................................................................................................................................. 6 Air Supply/Venting............................................................................................................................

SECTION I — GENERAL INFORMATION 1. GENERAL INFORMATION The boiler is designed specifically for forced draft firing, is available with oil, gas or combination gas/oil burners, and operates with a combustion efficiency of over 80%. This manual gives the necessary information for the proper installation, operation, maintenance and service of units. For special installation problems, contact Burnham Commercial, P.O. Box 3939 Lancaster, PA 17604, Phone: 888-791-3790 . 2.

SECTION II — INSTALLATION INSTRUCTIONS 1. BOILER PIPING Attach supply and return piping lines and insert plugs and bushings in connections as required. Supply and return piping headers are detailed in Figure 2. CAUTION IT IS IMPORTANT TO COMPLY WITH THE MINIMUM PIPING REQUIREMENTS IN ORDER TO ENSURE MAXIMUM PERFORMANCE AND RELIABILITY. ON STEAM BOILERS, PARTICULAR ATTENTION SHOULD BE GIVEN TO THE CONSTRUCTION OF THE SUPPLY HEADER.

6. FLUSHING THE BOILER All water contains some sediment which settles on the inside of the coil. Consequently, the heater should be periodically backwashed. This is accomplished by installing hose bibs as illustrated and allowing water at city pressure to run into hosebib A, through the heater, and out hosebib B until the discharge is clear. The tees in which the hosebibs are located should be the same size as heater connections to minimize pressure drop. 8 7.

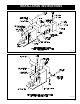

INSTALLATION INSTRUCTIONS FIGURE 3 FIGURE 4 TS-71-131-D TS-71-130-D 9

INSTALLATION INSTRUCTIONS FIGURE 5 TS-71-124-D FIGURE 6 TS-71-125-D NOTES: (1) When pump discharge piping exceeds 25 ft. install swing check valve at pump discharge. (2) If pump discharge is looped above normal boiler waterline, install a spring-loaded check valve at return header and at pump discharge.

INSTALLATION INSTRUCTIONS FIGURE 7 TS-71-157-C FIGURE 8 TS-71-155-D 11

INSTALLATION INSTRUCTIONS 12 FIGURE 9 TS-71-154-C FIGURE 10 TS-71-127-D

SECTION III — OPERATING INSTRUCTIONS 1. Always inspect installation before starting burner. 2. Fill heating system with water. IMPORTANT Any time that raw water is introduced to the boiler it must be heated to at least 180ºF immediately to dissipate the dissolved gases which can otherwise cause internal corrosion to the boiler. A. Steam Boilers Fill boiler to normal water line. Water should be visible in the gauge glass.

5. CLEANING A NEW STEAM BOILER Oil, grease & sediments which accumulate in a new boiler and piping must be removed from the system in order to prevent an unsteady water line and carryover of the water into the supply main above the boiler. Operate the boiler with steam in the entire system for a few days allowing the condensate to return to the boiler. If the condensate can temporarily be wasted, operate the boiler only for the length of time it takes for condensate to run clear.

8. BOILER WATER TREATMENT Boiler water treatment will help maximize the effectiveness and prolong the life of pressure vessels. The general objectives of boiler water treatment are: A. Remove corrosive gases from feedwater and boiler water. B. Prevent sludge and scale deposits on the water side heating surfaces. C. Prevent foaming and carryover.

SECTION IV — SERVICE INSTRUCTIONS IMPORTANT 1. IMPORTANT See item 10 under Operating Instruction if it becomes necessary to add water to the boiler more frequently than once a month. 2. GENERAL Inspection should be conducted annually. Service as frequently as specified in paragraphs below. Before service or maintenance is performed complete boiler shutdown/cooldown procedure. 3.

Clean firetubes with flue brush and reinstall turbulators. If turbulators are corroded or deteriorated, replacing them will ensure a high level of boiler efficiency. Remove soot and rust and reseal the boiler. 5. MAINTENANCE OF LOW WATER CUTOFF DEVICES IMPORTANT PROBE AND FLOAT TYPE LOW WATER CUTOFF DEVICES REQUIRE ANNUAL INSPECTION AND MAINTENANCE. A.

B. Steam Boilers Procedure for taking steam boilers off line at the end of heating season: Drain off boiler water until it runs clear while holding the boiler temperature between 180 and 200ºF. Then refill to top of gauge glass. C. Water Boilers Since a water boiler is a closed system, no draining/refilling should be necessary. 18 D. Note any time raw water is introduced into the boiler it must be immediately heated to 180°F to drive off dissolved gases.

PERIODIC TESTING RECOMMENDED CHECK LIST ITEM FREQUENCY ACCOMPLISHED BY REMARKS Gauges, monitors, and Daily Operator indicators Make visual inspection and record readings in log Instrument and equipment Daily Operator settings Make visual check against recommended specifications Firing rate control Verify factory settings Verify factory settings Check with combustion test Weekly Semi-annually Annually Operator Service Technician Service Technician Igniter Weekly Operator

PERIODIC TESTING RECOMMENDED CHECK LIST ITEM Atomizing Air/Steam FREQUENCY Annually ACCOMPLISHED BY REMARKS Service Technician Refer to burner instructions High and Low Gas Monthly Operator Pressure Interlocks Refer to burner instructions High and Low Oil Pressure Interlocks Monthly Operator Refer to burner instructions High and Low Oil Temperature Interlocks Monthly Operator Refer to burner instructions Fuel Valve Interlock Switch Annually Service Technician Refer to burner instruct

Commercial Boilers LIMITED WARRANTY LIMITED WARRANTY Subject to the terms and conditions herein, Seller warrants to the original owner at the original installation site that products manufactured by Seller (“Products”) comply, at the time of manufacture, with recognized hydronics industry regulatory agency standards and requirements therein effect and will be free from defects in materials and workmanship for a period of 12 months after the date of start-up or 18 months after the date of shipment, whichever