Install Instructions

38

EMP

Installation & Service Manual

109529-03 - 11/19

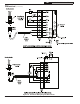

Figure 27: Electrode Settings

2. PRESS RED RESET BUTTON on burner

primary control, hold for ten (10) seconds and

release to reset the control.

3. THE BOILER CONTROL is factory set with a

High Limit setpoint of 190°F. The High Limit

setpoint is adjustable between 100°F and

220°F. This temperature may be varied to suit

the installation requirements.

4. CHECKOUT

Put the system into operation and observe at

least one complete cycle to make sure that the

controller operates properly.

E. CHECK / ADJUST OIL BURNER BEFORE

STARTING.

Natural Vent Applications:

1. Check Burner Settings and readjust if

necessary, see Burner Specifications, Tables

9A and 9B at the rear of this manual. Turn off

power to burner before proceeding.

2. Beckett Burners

a. Remove Gun Assembly.

b. Verify nozzle size, head size, gun setting,

and positioning of electrodes. This

information is shown in Figure 28, and

Beckett AFG Burner Specifications, Table

9A. Replace Gun Assembly.

c. Inspect Beckett head setting on left side

of burner housing by insuring the blue line

MD(V1) or the line on the label MB(L1) are

aligned, readjust if necessary. Refer to

Figure 28 and Table 9A at the rear of this

manual.

d. Check burner air band and air shutter

settings. Readjust if necessary, see Burner

Specifications Table 9A at the rear of this

manual.

e. OPEN ALL SHUT-OFF VALVES in the oil

supply line to the burner.

f. ATTACH A PLASTIC HOSE TO FUEL PUMP

VENT/BLEED FITTING and place the other

hose end into an empty container to catch

the oil.

g. SLIGHTLY OPEN FLAME OBSERVATION

PORT COVER on burner swing door,

enough to insert draft gauge probe later.

3. Carlin Burners

a. Remove nozzle line electrode assembly

from burner.

b. Verify the desired nozzle; refer to Table 9B

at the rear of this manual, for proper nozzle.

The nozzle must be securely installed to

assure leak free joints between the nozzle

and adapter. When installing the nozzle,

be careful not to bump or move the burner

electrodes.

c. Reinstall Flame Retention Head on Nozzle

Line Electrode Assembly. Make sure the

clamp is fully sated against the shoulder on

the nozzle adapter before securing.

d. Loosen and remove the retaining nut and

factory installed head bar from side of

burner housing. Install the proper head bar

that corresponds to the desired firing rate,

refer to Table 9B, and tighten retaining nut.

e. Readjust air band to preliminary setting that

corresponds to the nozzle installed, refer

to Table 9B. Inspect and measure burner

electrodes. Refer to Figure 27 for proper

electrode setting. Readjust electrode setting

to the proper dimensions if necessary.

f. Reinstall nozzle line electrode assembly.

g. Reconnect copper connector tube. Tighten

knurled nut. Close igniter, rotate and tighten

two (2) igniter latching screws.

h. Inspect Carlin head setting on left side

of burner to ensure that the proper head

positioning bar matches the nozzle that is

installed in drawer assembly refer to Table

9B.

Direct Vent Applications:

4. Beckett NX Burners

a. Verify nozzle size, gun setting and

positioning of electrodes. See Figures

29 through 31 and Beckett NX Burner

Specifications, Table 10 at the rear of this

manual.

b. Remove burner cover by loosening the four

thumb screws and set aside.

8 System Start-Up (continued)